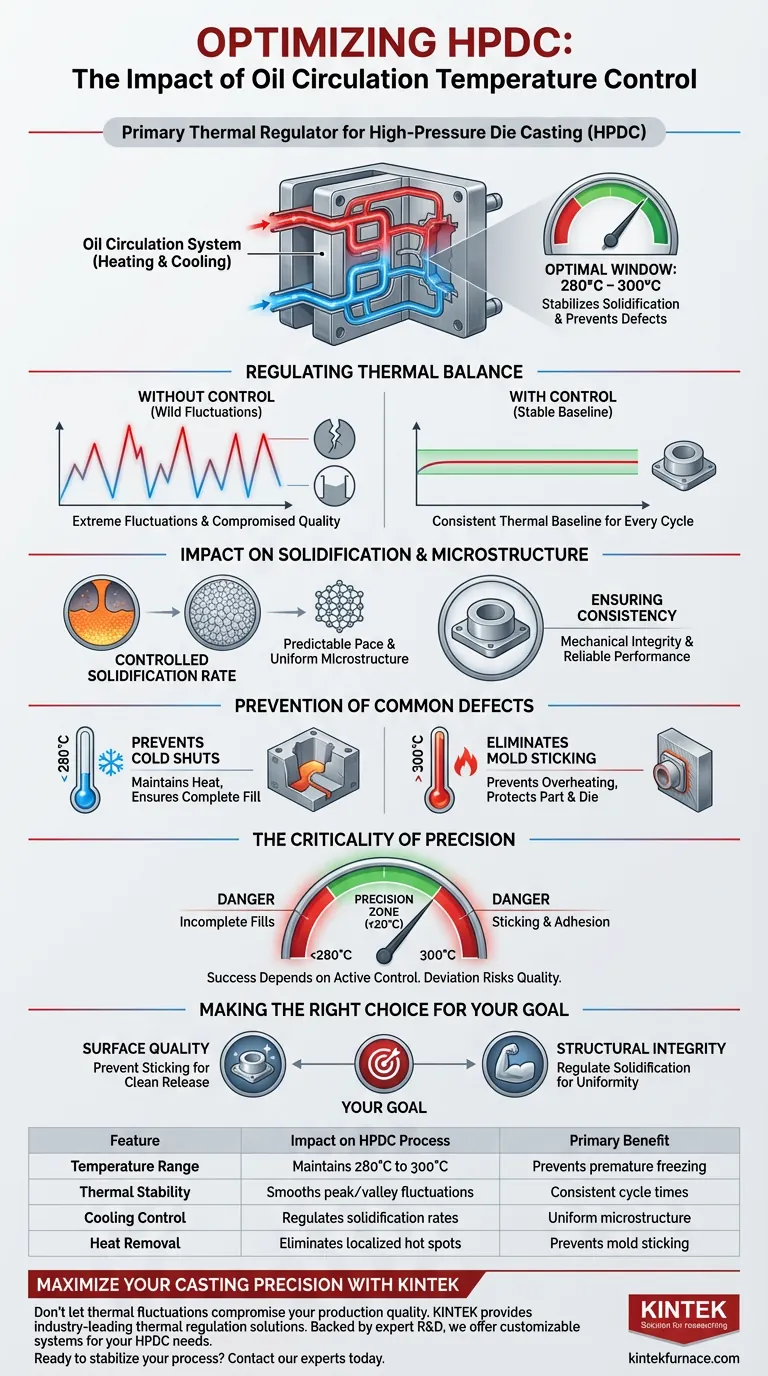

An oil circulation heating and cooling temperature control system acts as the primary thermal regulator for the high-pressure die casting (HPDC) process. Its function is to actively maintain the mold temperature within a precise, optimal window—typically between 280°C and 300°C—to stabilize the solidification of the liquid alloy and prevent temperature-related defects.

By stabilizing the thermal balance of the mold, this system eliminates the extreme temperature fluctuations that compromise part quality. It ensures the mold is neither too cold, which causes premature freezing, nor too hot, which leads to adhesion issues.

Regulating Thermal Balance

To understand the impact of an oil circulation system, you must look at how it manages the thermal energy within the mold tool.

Establishing the Optimal Window

The system is designed to lock the mold temperature into a specific range, usually 280°C to 300°C.

Stabilizing the Process

Without active control, a mold's temperature fluctuates wildly as hot metal is injected and the part is ejected. This system smooths out these peaks and valleys, creating a consistent thermal baseline for every cycle.

Impact on Solidification and Microstructure

The way the liquid alloy freezes determines the mechanical properties of the final part.

Controlling Solidification Rates

The system regulates the solidification rate of the liquid alloy within the cavity. By preventing the mold from acting as an uncontrolled heat sink, it allows the metal to cool at a predictable pace.

Ensuring Microstructural Consistency

Consistent cooling leads to a consistent internal structure. The system ensures a uniform distribution of microstructural components, which is essential for the mechanical integrity of the casting.

Prevention of Common Defects

The primary value of the system lies in its ability to mitigate specific defects caused by thermal mismanagement.

Preventing Cold Shuts

If a mold is too cold, the metal may freeze before it completely fills the cavity. By maintaining heat, the system prevents these cold shuts and ensures complete fill.

eliminating Mold Sticking

Conversely, if a mold overheats or develops hot spots, the alloy may adhere to the tool surface. The cooling capability of the system prevents this mold sticking, protecting both the part surface and the die itself.

The Criticality of Precision (Trade-offs)

While an oil circulation system is a powerful tool, its effectiveness relies entirely on the precision of its settings.

The Consequence of Deviation

The system operates within a relatively narrow margin (20°C variance). Falling below 280°C risks incomplete fills, while exceeding 300°C invites sticking.

Dependency on Thermal Balance

The process becomes highly dependent on this active control. Any failure in the circulation system immediately disrupts the thermal balance, reintroducing the temperature gradients that cause defects.

Making the Right Choice for Your Goal

The implementation of this system should be driven by the specific quality metrics you are trying to improve.

- If your primary focus is Surface Quality: The system is essential for preventing mold sticking, ensuring the casting releases cleanly without surface damage.

- If your primary focus is Structural Integrity: The precise temperature control regulates solidification, preventing cold shuts and ensuring a uniform microstructure across the part.

Success in HPDC relies on treating temperature as a controlled variable, not a random outcome.

Summary Table:

| Feature | Impact on HPDC Process | Primary Benefit |

|---|---|---|

| Temperature Range | Maintains 280°C to 300°C | Prevents premature freezing |

| Thermal Stability | Smooths peak/valley fluctuations | Consistent cycle times |

| Cooling Control | Regulates solidification rates | Uniform microstructure |

| Heat Removal | Eliminates localized hot spots | Prevents mold sticking |

Maximize Your Casting Precision with KINTEK

Don't let thermal fluctuations compromise your production quality. KINTEK provides industry-leading thermal regulation solutions designed for high-performance environments. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized lab high-temp furnaces tailored to your unique HPDC and material research needs.

Ready to stabilize your process? Contact our experts today to discover how our precision heating and cooling systems can enhance your lab or foundry's efficiency.

Visual Guide

References

- Guan Sheng, Yong Zhu. Microstructure and Mechanical Properties of High-Pressure Die-Casting Mg–Al–RE Alloys with Minor Ca Addition. DOI: 10.3390/ma18020231

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does a high-temperature annealing furnace regulate cold-rolled steel? Optimize Manganese Steel Performance

- What is the function of a laboratory drying oven in the preparation of solid bismuth molybdate materials? Expert Tips

- How does a precision temperature-controlled heating furnace enhance medium-entropy alloys? Achieve Optimal Hardness

- How is a constant temperature drying oven utilized to establish moisture content gradients in wood? Master the Baseline

- Why is a nitrogen protection system necessary for LPF resin synthesis? Ensure Purity in Lab Polymerization

- How is SEM utilized to evaluate manganese phosphate catalysts after calcination? Verify Nanosheet Integrity.

- What are the energy consumption considerations when choosing between separate or combined debinding and sintering furnaces? Optimize Your Process Efficiency

- How do a rotary evaporator and a constant temperature drying oven differ? Optimize Humic Sample Preparation