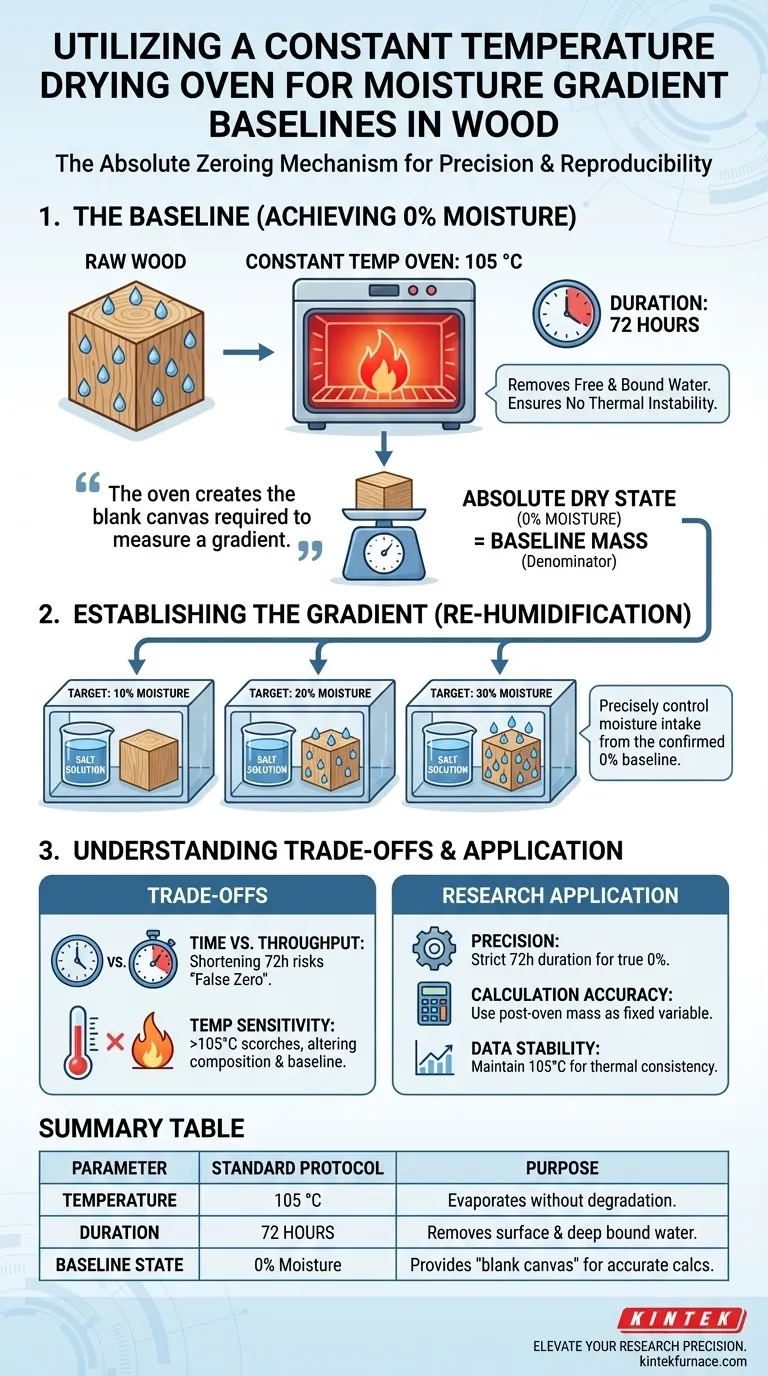

A constant temperature drying oven functions as the absolute zeroing mechanism in the creation of moisture content gradients. By subjecting wood samples to a sustained temperature of 105 °C for 72 hours, the oven removes all free and bound water to achieve an "absolute dry" state. This creates a known baseline of 0% moisture, which is the mandatory starting point for accurately calculating and regulating samples to higher specific moisture levels.

The drying oven does not create the gradient itself; rather, it creates the blank canvas required to measure a gradient. By ensuring a verified 0% moisture content, you eliminate initial variability, allowing for precise re-humidification to targets like 10%, 20%, or 30%.

The Physics of the Baseline

Achieving the Absolute Dry State

To establish a reliable gradient, you must first eliminate the unknown variables of existing moisture. The constant temperature oven is set to 105 °C, a temperature sufficient to evaporate water without chemically degrading the wood structure.

The Necessity of Duration

Heat alone is insufficient; duration is equally critical. For wood samples, the standard protocol requires a 72-hour cycle.

This extended duration ensures that not only surface moisture is evaporated, but also the "bound water" trapped deep within the cellular structure of the wood is fully released.

Ensuring Experimental Reproducibility

Removing this moisture prevents endothermic effects—where evaporating water absorbs heat—from interfering with subsequent experiments.

If moisture remains, it creates thermal instability and compromises the data. A fully dried sample ensures that any future measurements or combustion behaviors are properties of the wood itself, not the water content.

Establishing the Gradient

The Zero-Point Calculation

Once the wood reaches the absolute dry state, its mass represents the weight of the wood substance alone.

This dry weight serves as the denominator in the moisture content equation. Without this confirmed dry weight, calculating the amount of water needed to reach a specific percentage is merely an estimation.

The Re-humidification Process

After the oven cycle, the "zeroed" samples are subjected to moisture regulation methods, typically using saturated salt solutions.

Because the starting point was guaranteed to be 0% by the oven, researchers can precisely control the intake of moisture to hit exact steps in the gradient, such as 10%, 20%, or 30%.

Understanding the Trade-offs

Time vs. Throughput

The primary trade-off in this process is time. While some materials (like simple fuel samples) may only require 12 hours to remove physically adsorbed moisture, wood structures are more complex.

Shortening the 72-hour cycle to save time risks leaving bound water inside the sample. This results in a "false zero," which will skew every subsequent calculation in your gradient.

Temperature Sensitivity

Strict adherence to the 105 °C limit is vital.

Exceeding this temperature might dry the wood faster, but it risks scorching the organic material or altering its chemical composition (volatiles). This would corrupt the baseline mass and render the gradient inaccurate.

Applying This to Your Research

To ensure your moisture gradients are scientifically valid, you must treat the drying phase as the most critical step in sample preparation.

- If your primary focus is Precision: Adhere strictly to the 72-hour duration to guarantee the removal of all bound water for a true 0% baseline.

- If your primary focus is Calculation Accuracy: Use the mass obtained immediately after the oven cycle as your fixed variable for all subsequent moisture content equations.

- If your primary focus is Data Stability: Ensure the oven temperature does not fluctuate from 105 °C to prevent thermal degradation of the wood fibers.

An accurate moisture gradient is impossible without a perfect baseline; the drying oven provides the certainty required to build that baseline.

Summary Table:

| Parameter | Standard Protocol | Purpose for Gradient Establishment |

|---|---|---|

| Temperature | 105 °C | Evaporates water without chemical degradation (volatiles loss). |

| Duration | 72 Hours | Ensures removal of both surface free water and deep cellular bound water. |

| Baseline State | 0% Moisture | Provides a 'blank canvas' dry weight for accurate percentage calculations. |

| Key Outcome | Absolute Dry Mass | Eliminates thermal instability and ensures experimental reproducibility. |

Elevate Your Research Precision with KINTEK

Precise moisture gradients require uncompromising thermal stability. KINTEK provides high-performance drying ovens and lab high-temp furnaces designed to maintain exact temperature uniformity for critical sample preparation.

Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique wood science or material research needs. Don't compromise your baseline with temperature fluctuations—trust the experts in thermal processing.

Ready to optimize your laboratory drying process? Contact KINTEK today for a custom solution.

Visual Guide

References

- Yujie Wang, Zhongyuan Zhao. Research on the Factors Influencing the Thermoplastic Rheological Properties of Wood. DOI: 10.3390/f16010118

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How do laboratory high-temperature furnaces facilitate the control of nano-scale TiC and VC precipitates? | KINTEK

- What is the significance of using an Annealing Furnace in gas sensors? Enhance Stability and Sensitivity

- What are the technical advantages of using a six-zone resistance heating furnace in VGF-VB? Unlock Precision Growth

- What is the purpose of preheating low carbon steel molds to 300 °C before the casting of Mg-Zn-xSr alloys?

- Why is precise molar measurement of metal nitrates required during the preparation of high-entropy oxide precursor solutions? Ensure HEO Stability & Purity

- How does Thermogravimetric Analysis (TGA/DTG) provide industrial guidance? Optimize Blast Furnace Dust Treatment

- What are the limitations of PVD coating? Overcome Challenges for Optimal Surface Engineering

- What role does a high-temperature thermal simulation system play in the dissolution of precipitates in steel?