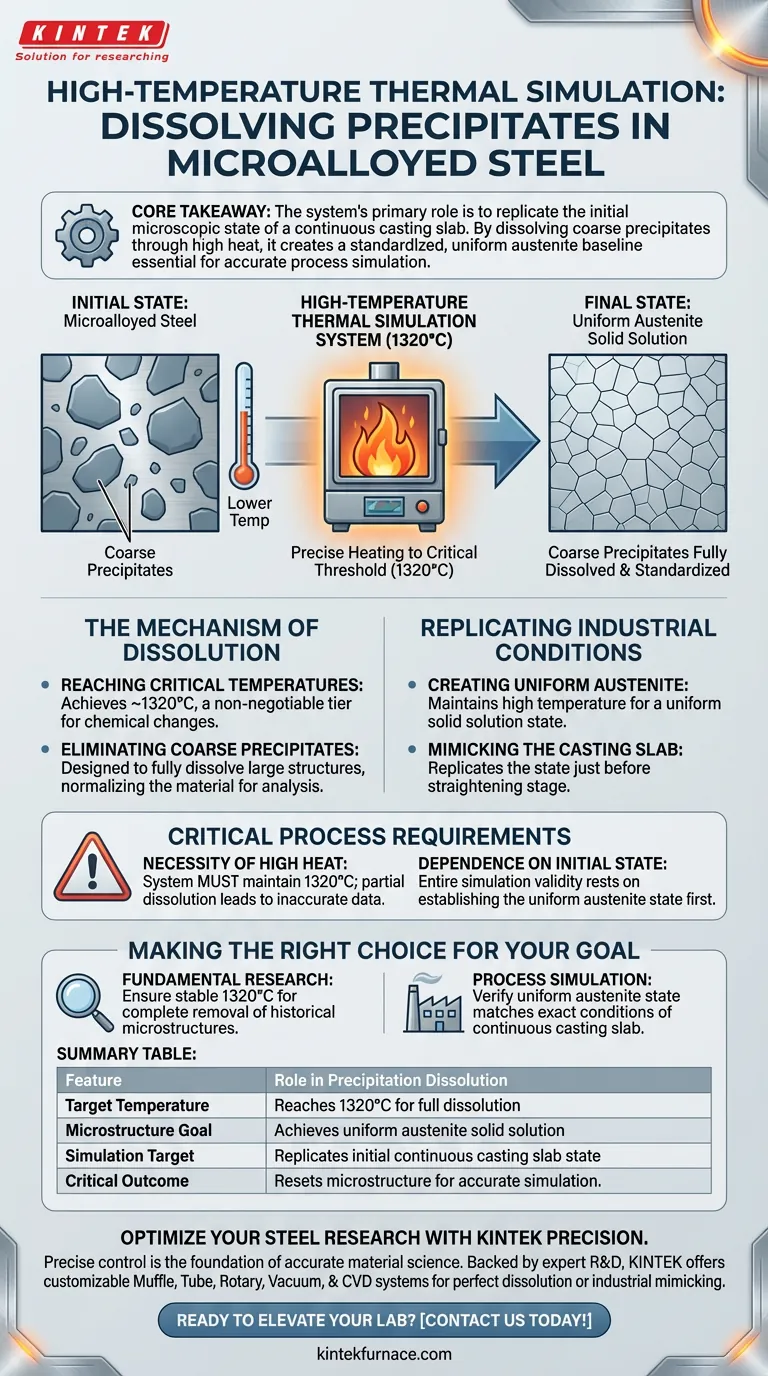

A high-temperature thermal simulation system serves as a precise microstructure reset mechanism. It utilizes efficient heating to raise microalloyed steel to approximately 1320°C, a critical threshold for fully dissolving coarse, pre-existing precipitates. By maintaining this temperature, the system forces the material into a uniform austenite solid solution state.

Core Takeaway The system's primary role is to replicate the initial microscopic state of a continuous casting slab. By dissolving coarse precipitates through high heat, it creates a standardized, uniform austenite baseline essential for accurate process simulation.

The Mechanism of Dissolution

Reaching Critical Temperatures

To affect the microstructure of microalloyed steel, the system must achieve extreme thermal conditions.

It uses an efficient heating mechanism to reach temperatures as high as 1320°C. This specific thermal tier is non-negotiable for the intended chemical changes.

Eliminating Coarse Precipitates

At lower temperatures, steel often contains large, coarse precipitates.

The high-temperature simulation system is designed specifically to fully dissolve these existing structures. This dissolution is the first step in normalizing the material for analysis.

Replicating Industrial Conditions

Creating Uniform Austenite

Once the precipitates are dissolved, the steel enters a solid solution state.

The system maintains the high temperature to ensure this state becomes a uniform austenite solid solution. This uniformity is crucial for consistent experimental data.

Mimicking the Casting Slab

The ultimate goal of this thermal process is contextual accuracy.

It is vital for accurately replicating the initial state of a continuous casting slab. Specifically, it mimics the material's condition just before it reaches the straightening stage of production.

Critical Process Requirements

The Necessity of High Heat

The simulation is binary in its success regarding temperature.

If the system fails to reach or maintain 1320°C, the coarse precipitates will not fully dissolve. Partial dissolution leads to an inaccurate representation of the material's potential.

Dependence on Initial State

The validity of the entire simulation rests on this initial heating phase.

If the uniform austenite state is not established first, subsequent tests will not reflect the reality of the production line. The system must perfectly replicate that specific moment in the continuous casting process to be useful.

Making the Right Choice for Your Goal

When utilizing thermal simulation for microalloyed steel, understanding the intent behind the heating cycle is key to data integrity.

- If your primary focus is Fundamental Research: Ensure your system can stably hold 1320°C to guarantee the complete removal of historical microstructures (coarse precipitates).

- If your primary focus is Process Simulation: Verify that the "uniform austenite" state matches the exact conditions of your specific continuous casting slab prior to straightening.

Accurate simulation begins with a perfectly reset microstructure.

Summary Table:

| Feature | Role in Precipitation Dissolution |

|---|---|

| Target Temperature | Reaches 1320°C to ensure full dissolution of coarse structures |

| Microstructure Goal | Achieves a uniform austenite solid solution state |

| Simulation Target | Replicates the initial state of a continuous casting slab |

| Critical Outcome | Resets microstructure for accurate straightening stage simulation |

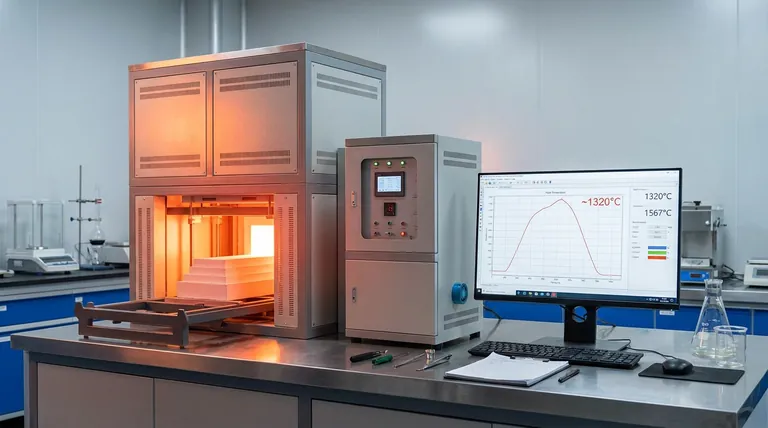

Optimize Your Steel Research with KINTEK Precision

Precise microstructure control is the foundation of accurate material science. Backed by expert R&D and manufacturing, KINTEK offers advanced Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temperature lab furnaces—all fully customizable to meet your unique thermal simulation needs. Whether you are aiming for perfect precipitate dissolution or mimicking industrial casting slabs, our equipment provides the stability and uniformity your research demands.

Ready to elevate your lab's performance? Contact us today to discuss your custom furnace solution!

Visual Guide

References

- Serkan Turan, Heinz Palkowski. Microscopic Investigation for Experimental Study on Transverse Cracking of Ti-Nb Containing Micro-Alloyed Steels. DOI: 10.3390/ma17040900

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does the introduction of SiO2 as an additive improve the sintering process of solid electrolytes? Boost Densification

- What is made in a dental lab? Discover the Custom Prosthetics for Your Smile

- Why are industrial-grade drying and crushing equipment necessary for pretreatment? Optimize Chemical Reactions

- How does a high-temperature laboratory furnace facilitate the pressureless sintering (PLS) of silicon nitride ceramics?

- Why is a 1:1 mixture of NaNO3 and KNO3 used in molten salt baths? Optimize Quenching Performance

- What core role does a magnetron sputtering system play in CrSiN-Y PVD? Unlock High-Performance Coating Precision

- What is the function of an industrial drying oven in ZnZrOx catalyst prep? Ensure Uniform Metal Precursor Adsorption

- What are the advantages of Spark Plasma Sintering (SPS) for diffusion bonding? Precision in Atomic Diffusion