In short, a dental laboratory creates custom-made dental prosthetics and appliances. These are highly precise devices, prescribed by a dentist, that restore a patient's oral function, health, and appearance. The most common items include crowns, bridges, dentures, and implant-borne restorations, all fabricated using specialized materials and technologies.

A dental laboratory is the critical link between a dentist's diagnosis and the final physical restoration. It is a center of technical artistry, translating a dentist's prescription into a functional and aesthetic device that improves a patient's quality of life.

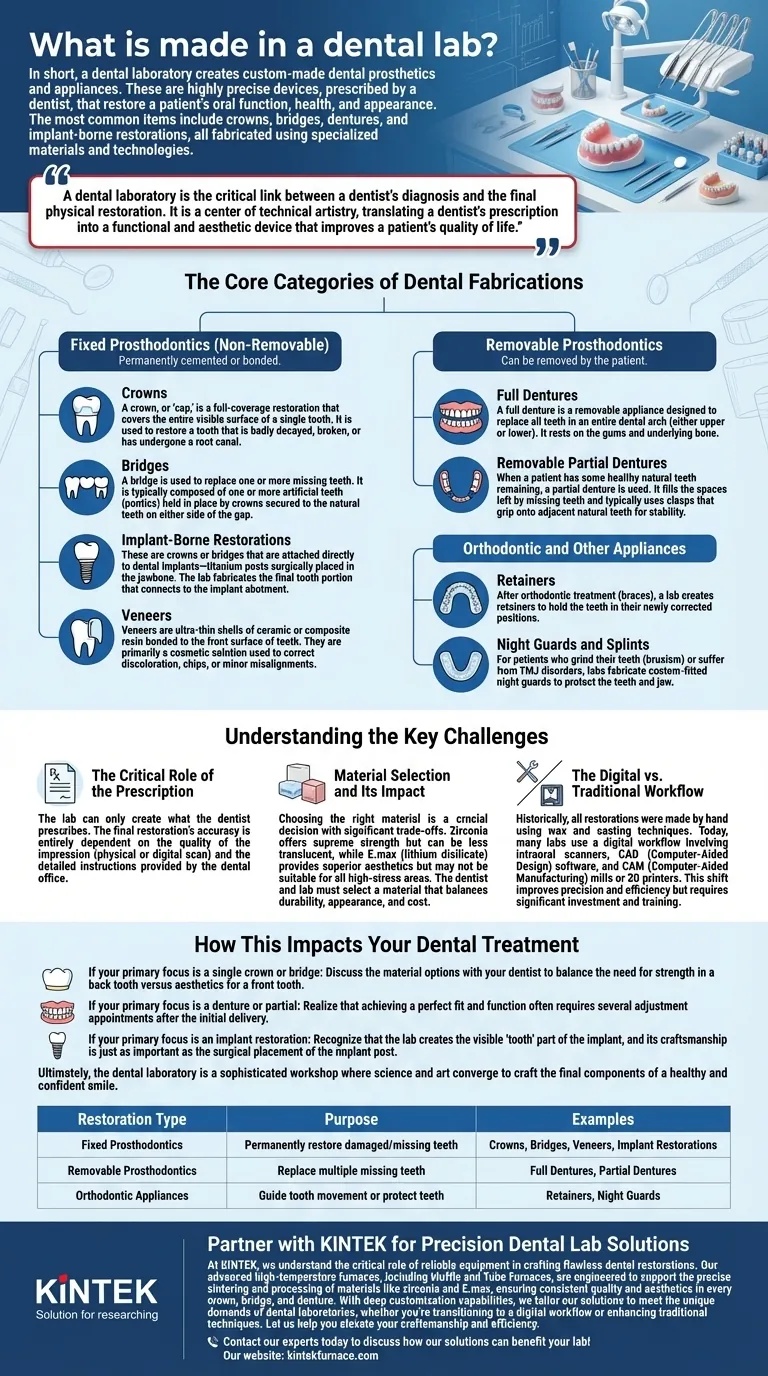

The Core Categories of Dental Fabrications

A dental lab’s work can be broadly divided into two main areas: fixed and removable prosthodontics. Each category serves a different purpose in restoring a patient's smile. Beyond these, labs also produce a variety of other specialized appliances.

Fixed Prosthodontics (Non-Removable)

These restorations are permanently cemented or bonded into place by a dentist and are not intended to be removed by the patient.

Crowns A crown, or "cap," is a full-coverage restoration that covers the entire visible surface of a single tooth. It is used to restore a tooth that is badly decayed, broken, or has undergone a root canal.

Bridges A bridge is used to replace one or more missing teeth. It is typically composed of one or more artificial teeth (pontics) held in place by crowns secured to the natural teeth on either side of the gap.

Implant-Borne Restorations These are crowns or bridges that are attached directly to dental implants—titanium posts surgically placed in the jawbone. The lab fabricates the final tooth portion that connects to the implant abutment.

Veneers Veneers are ultra-thin shells of ceramic or composite resin bonded to the front surface of teeth. They are primarily a cosmetic solution used to correct discoloration, chips, or minor misalignments.

Removable Prosthodontics

As the name implies, these devices can be removed by the patient for cleaning and while sleeping. They are often used when multiple teeth are missing.

Full Dentures A full denture is a removable appliance designed to replace all teeth in an entire dental arch (either upper or lower). It rests on the gums and underlying bone.

Removable Partial Dentures When a patient has some healthy natural teeth remaining, a partial denture is used. It fills the spaces left by missing teeth and typically uses clasps that grip onto adjacent natural teeth for stability.

Orthodontic and Other Appliances

Beyond restorations, dental labs also fabricate appliances that guide tooth movement or protect the teeth.

Retainers After orthodontic treatment (braces), a lab creates retainers to hold the teeth in their newly corrected positions.

Night Guards and Splints For patients who grind their teeth (bruxism) or suffer from TMJ disorders, labs fabricate custom-fitted night guards to protect the teeth and jaw.

Understanding the Key Challenges

The quality of a lab-fabricated device depends on a seamless collaboration between the dentist and the lab technician. Any breakdown in this process can compromise the final result.

The Critical Role of the Prescription

The lab can only create what the dentist prescribes. The final restoration's accuracy is entirely dependent on the quality of the impression (physical or digital scan) and the detailed instructions provided by the dental office.

Material Selection and Its Impact

Choosing the right material is a crucial decision with significant trade-offs. Zirconia offers supreme strength but can be less translucent, while E.max (lithium disilicate) provides superior aesthetics but may not be suitable for all high-stress areas. The dentist and lab must select a material that balances durability, appearance, and cost.

The Digital vs. Traditional Workflow

Historically, all restorations were made by hand using wax and casting techniques. Today, many labs use a digital workflow involving intraoral scanners, CAD (Computer-Aided Design) software, and CAM (Computer-Aided Manufacturing) mills or 3D printers. This shift improves precision and efficiency but requires significant investment and training.

How This Impacts Your Dental Treatment

Understanding the lab's role helps you appreciate the precision and artistry involved in your dental care and allows for more informed conversations with your dentist.

- If your primary focus is a single crown or bridge: Discuss the material options with your dentist to balance the need for strength in a back tooth versus aesthetics for a front tooth.

- If your primary focus is a denture or partial: Realize that achieving a perfect fit and function often requires several adjustment appointments after the initial delivery.

- If your primary focus is an implant restoration: Recognize that the lab creates the visible "tooth" part of the implant, and its craftsmanship is just as important as the surgical placement of the implant post.

Ultimately, the dental laboratory is a sophisticated workshop where science and art converge to craft the final components of a healthy and confident smile.

Summary Table:

| Restoration Type | Purpose | Examples |

|---|---|---|

| Fixed Prosthodontics | Permanently restore damaged/missing teeth | Crowns, Bridges, Veneers, Implant Restorations |

| Removable Prosthodontics | Replace multiple missing teeth | Full Dentures, Partial Dentures |

| Orthodontic Appliances | Guide tooth movement or protect teeth | Retainers, Night Guards |

Partner with KINTEK for Precision Dental Lab Solutions

At KINTEK, we understand the critical role of reliable equipment in crafting flawless dental restorations. Our advanced high-temperature furnaces, including Muffle and Tube Furnaces, are engineered to support the precise sintering and processing of materials like zirconia and E.max, ensuring consistent quality and aesthetics in every crown, bridge, and denture.

With deep customization capabilities, we tailor our solutions to meet the unique demands of dental laboratories, whether you're transitioning to a digital workflow or enhancing traditional techniques. Let us help you elevate your craftsmanship and efficiency.

📞 Contact our experts today to discuss how our solutions can benefit your lab!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations