The specific utility of a 1:1 mixture of sodium nitrate and potassium nitrate lies in its ability to mechanically and thermally optimize the quenching environment. By combining these salts in equal measure, heat treaters achieve a medium with superior fluidity and stability, which are critical for consistent metallurgical results.

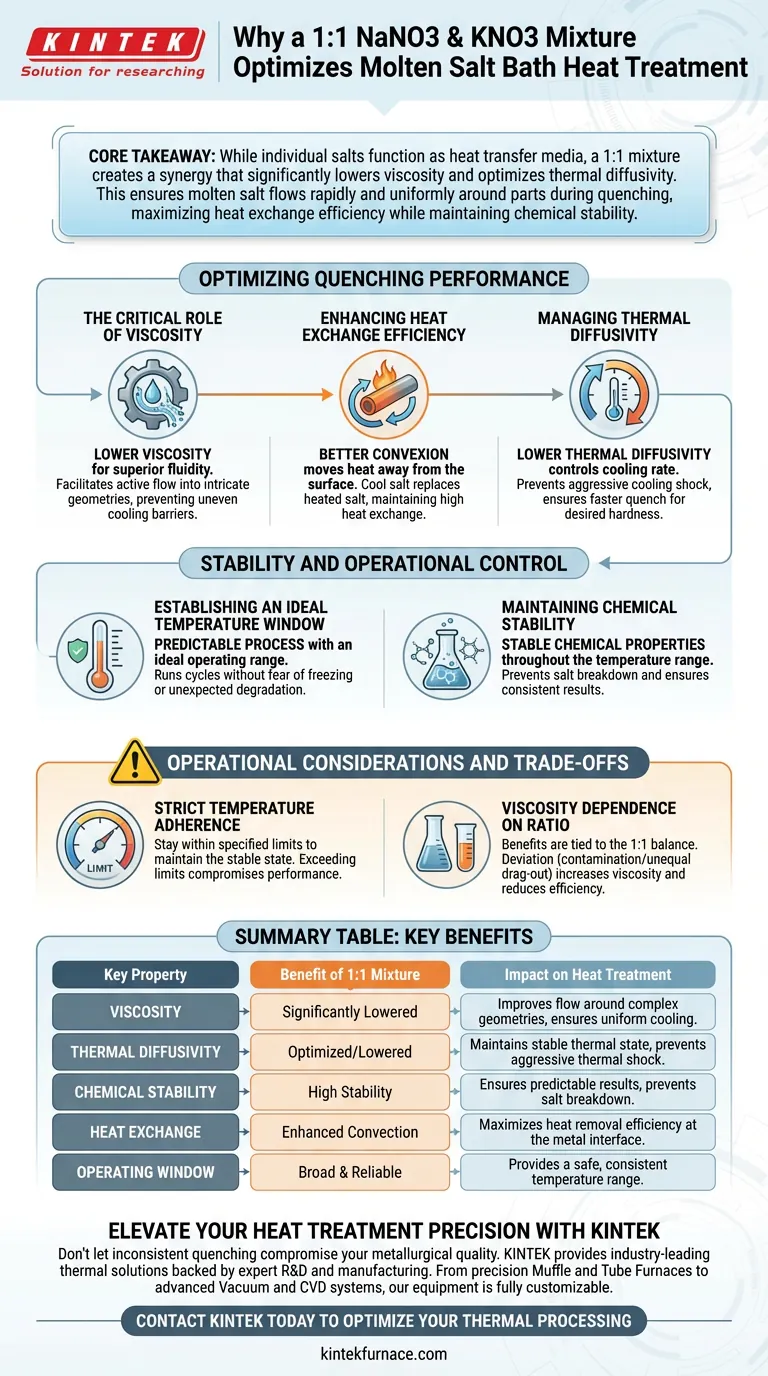

Core Takeaway While individual salts function as heat transfer media, a 1:1 mixture creates a synergy that significantly lowers viscosity and optimizes thermal diffusivity. This ensures the molten salt flows rapidly and uniformly around parts during quenching, maximizing heat exchange efficiency while maintaining chemical stability within the processing window.

Optimizing Quenching Performance

The Critical Role of Viscosity

The primary operational advantage of this mixture is its lower viscosity. High-viscosity fluids move sluggishly, which can create uneven cooling barriers around a hot part.

By using a 1:1 ratio, the salt bath becomes more fluid. This facilitates the active flow of molten salt during the quenching process, ensuring the medium can circulate into intricate geometries.

Enhancing Heat Exchange Efficiency

The flow characteristics directly dictate how effectively heat is removed from the metal. Lower viscosity facilitates better convection, which is the mechanism for moving heat away from the part's surface.

This leads to enhanced cooling performance. The mixture ensures that fresh, cooler salt is constantly replacing the heated salt at the interface of the metal, maintaining high heat exchange efficiency.

Managing Thermal Diffusivity

The mixture is characterized by lower thermal diffusivity. This property relates to how quickly the material itself changes temperature.

By controlling diffusivity, the bath maintains a stable thermal state. This helps in regulating the rate at which the part cools, preventing the shock of overly aggressive cooling while ensuring the quench is fast enough to achieve desired hardness.

Stability and Operational Control

Establishing an Ideal Temperature Window

Process control relies on predictability. The 1:1 mixture provides an ideal operating temperature window, allowing operators to run cycles without fear of the medium freezing or degrading unexpectedly.

Maintaining Chemical Stability

Beyond thermal mechanics, the chemical integrity of the bath is vital. This specific nitrate combination maintains stable chemical properties throughout its specified temperature range.

This stability prevents the breakdown of the salt, which could otherwise lead to inconsistent results or safety hazards during the heat treatment process.

Operational Considerations and Trade-offs

Strict Temperature Adherence

While the mixture creates a stable environment, it relies on staying within the specified temperature ranges. Exceeding these limits can compromise the stable state described above, potentially altering the salt's performance.

Viscosity Dependence on Ratio

The benefits of enhanced flow and cooling are tied to the specific mixture properties. Significant deviation from the 1:1 balance (through contamination or unequal drag-out) could increase viscosity, thereby reducing the heat exchange efficiency that justifies using this mixture in the first place.

Making the Right Choice for Your Process

To determine if this mixture aligns with your metallurgical goals, consider your specific quenching requirements:

- If your primary focus is Complex Geometry: Leverage the lower viscosity of this mixture to ensuring adequate flow and heat removal in tight corners and recesses.

- If your primary focus is Process Consistency: Rely on the stable chemical properties of the 1:1 ratio to minimize variables and maintain a predictable operating window over time.

By utilizing this specific mixture, you ensure that the physical properties of the quench medium actively support, rather than hinder, your heat treatment objectives.

Summary Table:

| Key Property | Benefit of 1:1 Mixture | Impact on Heat Treatment |

|---|---|---|

| Viscosity | Significantly Lowered | Improves flow around complex geometries and ensures uniform cooling. |

| Thermal Diffusivity | Optimized/Lowered | Maintains a stable thermal state and prevents aggressive thermal shock. |

| Chemical Stability | High Stability | Ensures predictable results and prevents salt breakdown during cycles. |

| Heat Exchange | Enhanced Convection | Maximizes heat removal efficiency at the metal interface. |

| Operating Window | Broad & Reliable | Provides a safe, consistent temperature range for industrial processing. |

Elevate Your Heat Treatment Precision with KINTEK

Don't let inconsistent quenching compromise your metallurgical quality. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. From precision Muffle and Tube Furnaces to advanced Vacuum and CVD systems, our equipment is fully customizable to meet your unique laboratory or industrial needs.

Ready to optimize your thermal processing? Contact KINTEK today to discover how our high-temperature systems can enhance your efficiency and consistency.

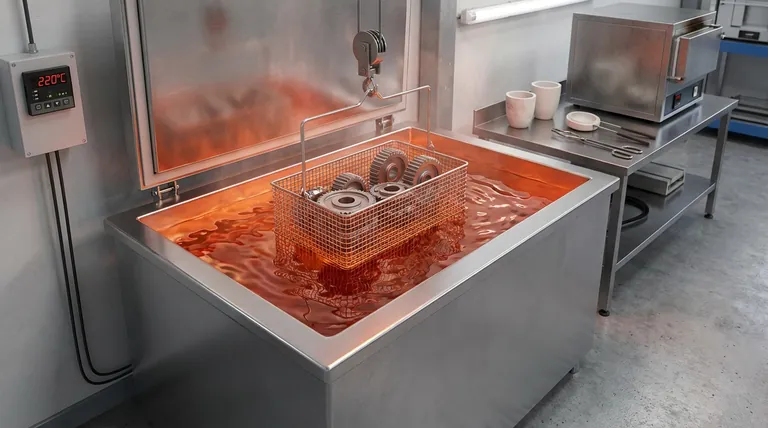

Visual Guide

References

- Jun Li, Jieyu Zhang. A Novel Design of a Molten Salt Bath Structure and Its Quenching Effect on Wire Transformation from Austenite to Sorbite. DOI: 10.3390/met14040483

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why must g-C3N4 thin films be metal-coated before SEM? Achieve High-Resolution Imaging with Vacuum Deposition

- How does the use of a stainless steel high-pressure autoclave affect ZnS/CeO2@CNT formation? Optimize Catalyst Growth

- Why do Axial Flame Burners produce high NOx? Managing Thermal Intensity in Oxygen-Enhanced Combustion

- What is the impact of microwave power on the synthesis of 2D metal oxides? Master High-Speed Material Production

- What is the core function of a drying furnace in mold preparation? Build High-Strength Inorganic Silicate Molds

- Why is precise temperature control in an aging oven critical for ZK61 alloys? Master the 175°C Pre-aging Threshold

- What are the advantages of ascorbic acid over glucose in LFP synthesis? Achieve Superior Purity and Crystallinity

- What is the function of ball milling in Li-NASICON synthesis? Optimize Your Solid Electrolyte Performance