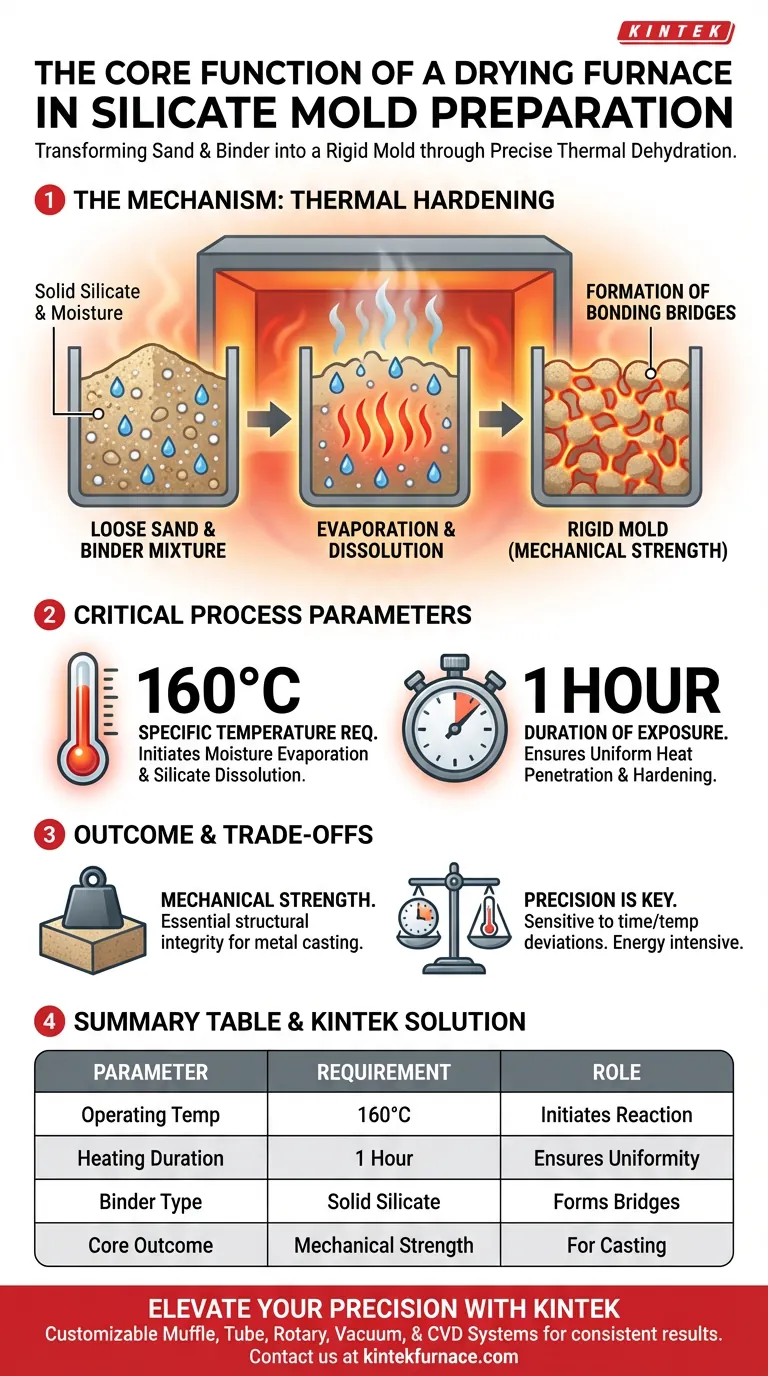

The core function of a drying furnace in this context is to provide a controlled thermal environment that initiates the hardening of the sand mold. By maintaining a temperature of 160°C for one hour, the furnace drives the evaporation of moisture, a critical step that allows solid silicate powder to dissolve and reform into structural bonding bridges.

The drying furnace serves as the catalyst for mechanical strength, transforming a loose sand-binder mixture into a rigid mold by activating the inorganic silicate through precise thermal dehydration.

The Mechanism of Thermal Hardening

To understand why the furnace is indispensable, one must look at the chemical and physical changes occurring within the mold.

Evaporation and Dissolution

The primary role of the furnace is to facilitate the evaporation of moisture present in the mixture.

This thermal energy triggers a reaction where the solid silicate powder dissolves. This dissolution phase is the precursor to the structural changes required for the mold to function.

Formation of Bonding Bridges

As the process continues, the dissolved silicate does not simply dry out; it undergoes a transformation.

The silicate reforms to create strong bonding bridges between the sand grains. These bridges are the physical connections that hold the mold together, turning granular sand into a solid block.

Process Parameters and Outcomes

The effectiveness of the drying furnace relies on adhering to specific operational parameters defined by the binder's properties.

Specific Temperature Requirements

The standard requirement for this process is heating the sand mold at 160°C.

This temperature is sufficient to drive the reaction without damaging the fundamental structure of the mold components.

Duration of Exposure

The mold must be held at this temperature for one hour.

This duration ensures that the heat penetrates the entire volume of the sand mold, ensuring uniform hardening from the surface to the core.

Mechanical Strength

The ultimate output of this thermal processing is mechanical strength.

Without this heating cycle, the mold would lack the structural integrity necessary to support the weight and pressure of the subsequent metal casting process.

Understanding the Trade-offs

While the drying furnace is effective, it introduces specific constraints that must be managed to ensure quality.

Sensitivity to Process Deviations

The process relies on a specific balance of time and temperature (160°C for one hour).

Deviating from these metrics can result in incomplete bonding. If the moisture is not fully evaporated or the silicate does not fully reform, the mold may fail under the stress of casting.

Energy Dependence

This method of mold preparation is inherently energy-intensive due to the requirement of sustained heating.

Efficiency in this stage is dictated by the furnace's ability to maintain a stable temperature, making equipment reliability a critical factor in production success.

Making the Right Choice for Your Goal

The drying furnace is not just a heater; it is a reactor that finalizes the mold's physical properties.

- If your primary focus is Mold Integrity: Strictly adhere to the 160°C setpoint to ensure the bonding bridges form completely.

- If your primary focus is Process Consistency: Ensure the one-hour duration is measured accurately to guarantee uniform strength throughout the mold.

Precision in the drying phase is the defining factor between a fragile mixture and a casting-ready mold.

Summary Table:

| Process Parameter | Requirement | Role in Mold Preparation |

|---|---|---|

| Operating Temperature | 160°C | Initiates moisture evaporation and silicate dissolution |

| Heating Duration | 1 Hour | Ensures uniform hardening and full heat penetration |

| Binder Type | Solid Inorganic Silicate | Forms structural bonding bridges between sand grains |

| Core Outcome | Mechanical Strength | Provides structural integrity for metal casting pressure |

Elevate Your Foundry Precision with KINTEK

Achieving consistent mechanical strength in your molds requires more than just heat—it requires precision. Backed by expert R&D and manufacturing, KINTEK offers high-performance laboratory and industrial heating solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to your unique thermal processing needs.

Whether you are refining silicate binder recipes or scaling up production, our furnaces provide the temperature stability and reliability essential for success. Contact us today to optimize your mold preparation process and see how our tailored thermal technology can transform your lab or foundry efficiency.

Visual Guide

References

- Nurul Anwar, Juhani Orkas. Effect of Additives on Heat Hardened Inorganic Solid Foundry Binder. DOI: 10.1007/s40962-024-01277-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How do laboratory tablet presses ensure performance in iodine battery prototypes? Optimize Interfacial Contact Today

- How does a high-sensitivity non-contact microphone assist in detecting cracks during the solidification of molten slag?

- What is the function of an industrial electric furnace in Al-Cu 224 alloy preparation? Optimize Your Metal Production

- How do heat exchangers contribute to energy efficiency? Boost Your Hybrid Power System Performance

- What are the advantages of using microwave plasma for aluminum powder reduction? Achieve Unmatched Material Purity

- How does a sputtering system contribute to the preparation of electrodes? Enhance Bismuth Telluride Characterization

- How does the 1600°C range influence biomass microstructure? Transform Carbon into High-Performance Graphite

- What are the characteristics of a Batch Reactor for plastic pyrolysis? A Guide to Versatile Waste Processing