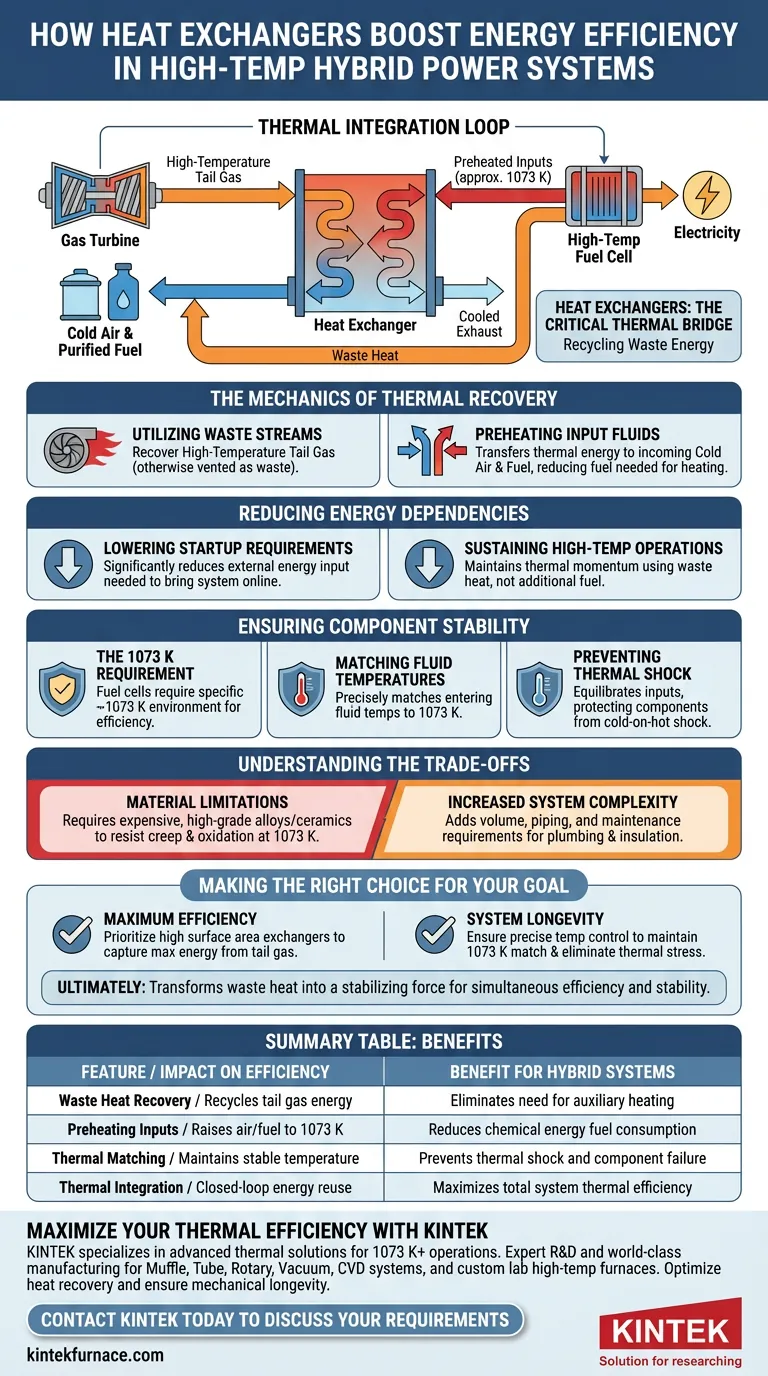

Heat exchangers serve as the critical thermal bridge in high-temperature hybrid power systems by recycling waste energy. Specifically, they utilize the high-temperature tail gas expelled from the gas turbine to preheat incoming cold air and purified fuel. This creates a thermal integration loop that drastically reduces the need for external heating to sustain the system.

By capturing waste heat from the turbine and using it to bring fuel and air to the required 1073 K operating temperature, heat exchangers eliminate the need for auxiliary heating and protect the fuel cell from thermal shock, directly driving up total thermal efficiency.

The Mechanics of Thermal Recovery

Utilizing Waste Streams

The process begins with the recovery of high-temperature tail gas from the gas turbine.

In a standard setup, this heat might be vented into the atmosphere as waste. In a hybrid system, it is captured as a valuable resource.

Preheating Input Fluids

This recovered thermal energy is transferred directly to the incoming streams of cold air and purified fuel.

By heating these inputs before they enter the reaction chamber, the system reduces the chemical energy required purely for heating, allowing more fuel to be converted into electricity.

Reducing Energy Dependencies

Lowering Startup Requirements

Heat exchangers significantly reduce the external energy input needed to bring the system online.

Without this recovery mechanism, the system would require substantial auxiliary power to heat massive amounts of air and fuel from ambient temperature to operating levels.

Sustaining High-Temperature Operations

Once the system is running, the heat exchanger maintains the thermal momentum.

It ensures the system can sustain high-temperature operations largely through its own waste heat, rather than burning additional fuel solely to maintain thermal mass.

Ensuring Component Stability

The 1073 K Requirement

High-temperature fuel cells within these hybrid systems typically require a specific operating environment, often around 1073 K.

Operating deviations from this temperature can result in inefficient reactions or system failure.

Matching Fluid Temperatures

The heat exchanger ensures that the fluid temperatures entering the fuel cell precisely match this 1073 K environment.

Preventing Thermal Shock

By equilibrating the temperature of the inputs with the reactor, the heat exchanger prevents cold fluids from hitting hot components.

This thermal matching is essential for the mechanical longevity of the ceramic or metallic components inside the fuel cell.

Understanding the Trade-offs

Material Limitations

Operating heat exchangers at 1073 K places immense stress on materials.

The components must be constructed from expensive, high-grade alloys or ceramics to resist creep and oxidation at these extreme temperatures.

Increased System Complexity

Integrating recovery units adds volume and piping complexity to the power system.

While efficiency increases, the physical footprint and the maintenance requirements for the plumbing and thermal insulation also increase.

Making the Right Choice for Your Goal

When designing or evaluating a high-temperature hybrid system, consider how the heat exchanger aligns with your primary objectives:

- If your primary focus is Maximum Efficiency: Prioritize heat exchangers with high surface areas to capture the maximum amount of energy from the turbine tail gas.

- If your primary focus is System Longevity: Ensure the recovery unit provides precise temperature control to maintain the 1073 K match and eliminate thermal stress on the fuel cell.

Ultimately, the heat exchanger transforms waste heat into a stabilizing force, making high efficiency and operational stability possible simultaneously.

Summary Table:

| Feature | Impact on Efficiency | Benefit for Hybrid Systems |

|---|---|---|

| Waste Heat Recovery | Recycles tail gas energy | Eliminates need for auxiliary heating |

| Preheating Inputs | Raises air/fuel to 1073 K | Reduces chemical energy fuel consumption |

| Thermal Matching | Maintains stable temperature | Prevents thermal shock and component failure |

| Thermal Integration | Closed-loop energy reuse | Maximizes total system thermal efficiency |

Maximize Your Thermal Efficiency with KINTEK

Is your high-temperature system losing critical energy to waste heat? KINTEK specializes in advanced thermal solutions designed to withstand the rigors of 1073 K+ operations. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as custom-engineered lab high-temp furnaces tailored to your unique research or production needs.

Whether you are looking to optimize heat recovery or ensure mechanical longevity with precise temperature control, our team is ready to help you build a more efficient future.

Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Ivan Beloev, Iliya Iliev. Utilization of Hydrogen-Containing Gas Waste from Deep Oil Refining at a Hybrid Power Plant with a Solid Oxide Fuel Cell. DOI: 10.3390/engproc2024060005

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the primary objective of processing high-purity quartz? Achieve 99.998% Purity for Tech Applications

- What is the function of the 1500 °C environment in wood carbonization? Unlock High-Performance Functional Carbon

- What technical advantages do high-temperature furnace systems provide for robust flexible interconnects? Enhance Durability

- Why must nickel-based bimetallic catalyst precursors be treated in a blast drying oven? Prevent Structural Failure

- Why is a laboratory vacuum oven required for GO slurry? Preserving Chemical Integrity in Graphene Oxide Dehydration

- What is the use of a laboratory furnace? Unlock Precise Material Transformation

- Why is the calcination step essential for Copper Ferrite? Unlock High Purity & Superior Crystallinity

- What is the significance of high vacuum base pressure in MoS2 sputtering? Ensuring Film Purity and Stoichiometry