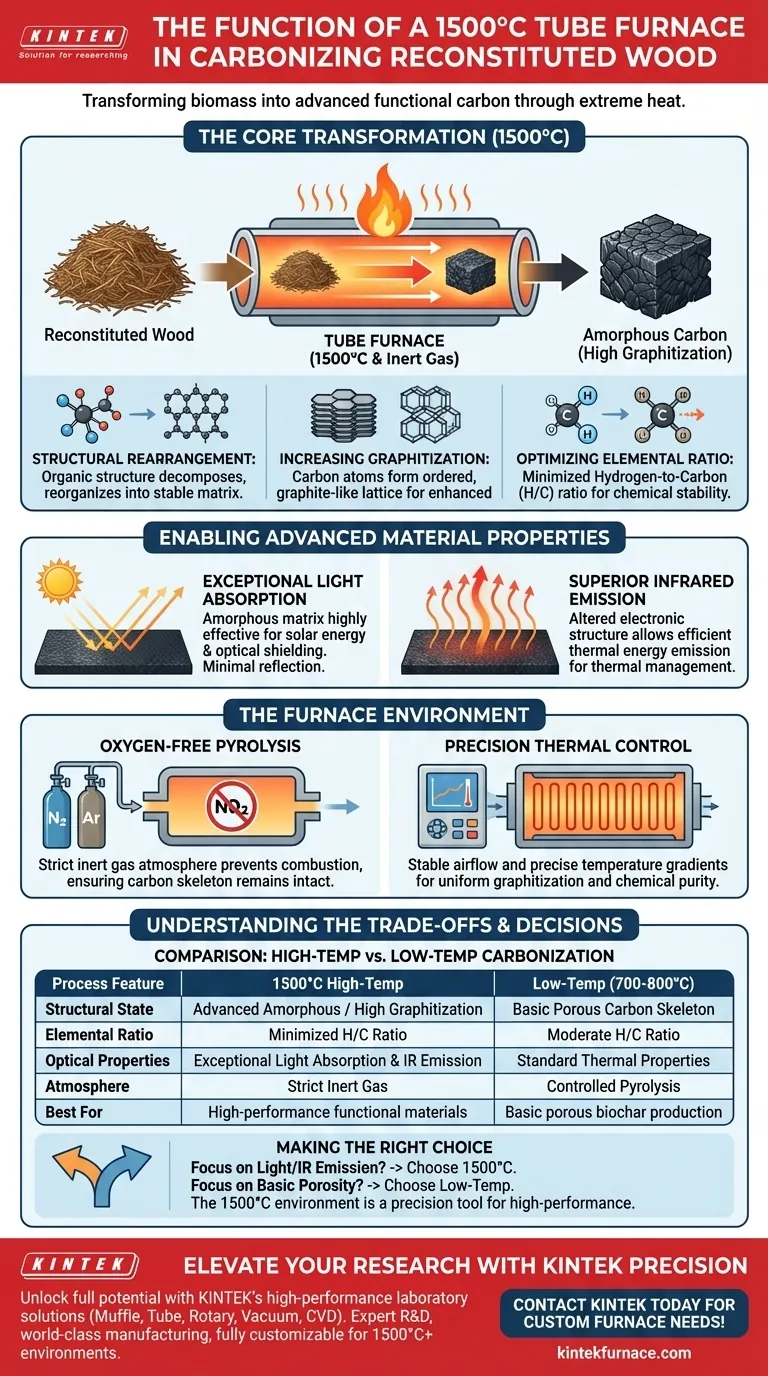

The primary function of the 1500 °C environment provided by a tube furnace is to drive the complete chemical decomposition and structural rearrangement required to transform reconstituted wood into amorphous carbon. This extreme thermal condition forces the material to undergo a deep structural evolution, resulting in a matrix characterized by a high degree of graphitization and a significantly minimized hydrogen-to-carbon (H/C) ratio.

The 1500 °C threshold is not merely about drying or charring; it is the critical processing condition for advanced functionalization. By pushing the material to this temperature, you unlock specific high-performance properties—namely exceptional light absorption and superior infrared emission—that are unattainable at lower carbonization temperatures.

The Physical and Chemical Transformation

Structural Rearrangement

At 1500 °C, the tube furnace facilitates a profound change in the wood's architecture. The heat causes the reconstituted wood to lose its original organic structure.

It reorganizes into a stable, amorphous carbon matrix. This structural shift is necessary to create a material that is robust and chemically pure.

Increasing Graphitization

A key function of this high-temperature environment is to increase the degree of graphitization. As the temperature rises, the carbon atoms arrange themselves into a more ordered, graphite-like lattice structure.

This ordering enhances the material's conductive and thermal properties. It differentiates high-performance carbon materials from simple charcoal.

Optimizing the Elemental Ratio

The 1500 °C heat drives off non-carbon elements, specifically hydrogen. This results in a very low hydrogen-to-carbon (H/C) ratio in the final product.

By minimizing hydrogen content, the furnace ensures the resulting carbon structure is dense and chemically stable. This purity is directly linked to the material's final performance characteristics.

Enabling Advanced Material Properties

Exceptional Light Absorption

The structural changes induced at 1500 °C grant the material specific optical capabilities. The resulting amorphous carbon matrix becomes highly effective at absorbing light.

This property is often essential for applications in solar energy conversion or optical shielding. The deep carbonization ensures minimal light reflection.

Superior Infrared Emission

Beyond visible light, the material gains superior infrared emission characteristics. The high-temperature treatment alters the electronic structure of the carbon.

This allows the material to emit thermal energy efficiently in the infrared spectrum. This is a critical feature for applications involving thermal management or radiative cooling.

The Role of the Furnace Environment

Oxygen-Free Pyrolysis

While the temperature is the primary driver, the tube furnace also maintains a strictly controlled atmosphere. To reach 1500 °C without burning the wood to ash, the furnace must utilize an inert gas environment (typically nitrogen or argon).

This oxygen-free setting allows for pyrolysis rather than combustion. It ensures that the carbon skeleton remains intact while volatile components are removed.

Precision Thermal Control

The tube furnace provides the stable airflow management and precise temperature gradients necessary for uniform results.

Fluctuations at these extreme temperatures can lead to inconsistent graphitization. The furnace ensures the entire sample experiences the exact conditions needed for the target porosity and elemental composition.

Understanding the Trade-offs

Energy Intensity vs. Material Quality

Reaching and maintaining 1500 °C requires significant energy input and specialized heating elements.

You must weigh this cost against the need for high graphitization. If your application does not require superior infrared emission, lower-temperature carbonization (e.g., 700–800 °C) may be more efficient.

Material Loss and Yield

At 1500 °C, the decomposition is "thorough," meaning a significant portion of the original mass is volatilized.

While this yields a purer carbon product, the overall material yield is lower compared to low-temperature biochar production. You are trading volume for performance density.

Making the Right Choice for Your Goal

The decision to utilize a 1500 °C tube furnace process depends entirely on the specific performance metrics your project demands.

- If your primary focus is Light Absorption/IR Emission: You must utilize the 1500 °C environment to achieve the necessary low H/C ratio and high graphitization.

- If your primary focus is Basic Porosity: Consider lower temperatures (700–800 °C), which are sufficient for creating porous skeletons without the energy cost of high-level graphitization.

The 1500 °C environment is a precision tool designed to elevate wood from a raw biomass material into a high-performance functional carbon component.

Summary Table:

| Process Feature | 1500°C High-Temp Carbonization | Low-Temp Carbonization (700-800°C) |

|---|---|---|

| Structural State | Advanced Amorphous Carbon / High Graphitization | Basic Porous Carbon Skeleton |

| Elemental Ratio | Minimized Hydrogen-to-Carbon (H/C) Ratio | Moderate H/C Ratio |

| Optical Properties | Exceptional Light Absorption & IR Emission | Standard Thermal Properties |

| Atmosphere | Strict Inert Gas (Oxygen-Free) | Controlled Pyrolysis |

| Best For | High-performance functional materials | Basic porous biochar production |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of advanced carbonization with KINTEK’s high-performance laboratory solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to withstand extreme 1500°C+ environments with pinpoint accuracy.

Whether you are developing next-generation solar energy materials or advanced thermal management components, our systems provide the uniform heating and atmosphere control necessary for superior graphitization and chemical purity. All our lab high-temp furnaces are fully customizable to meet your unique research requirements.

Ready to achieve consistent, high-performance results for your target customers and projects? Contact KINTEK today to discuss your custom furnace needs!

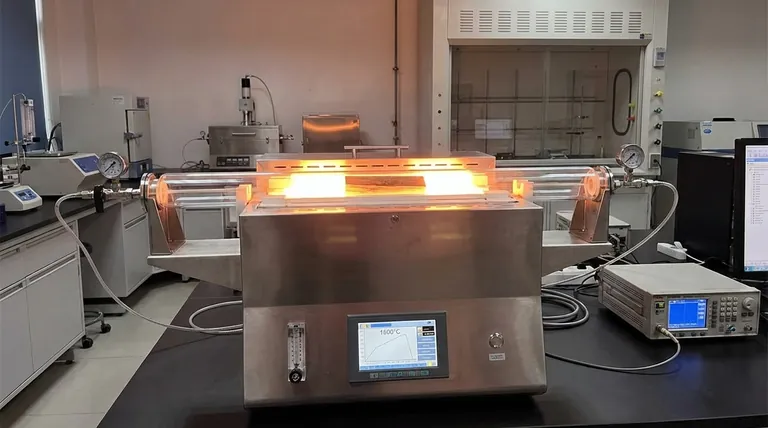

Visual Guide

References

- Bin Zhao, Bruno D. Mattos. Wood Reconfiguration Enables Broadband Blackbody in Large‐Area, Modular, Optically Welded Carbon Constructs. DOI: 10.1002/adfm.202506820

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the advantages of zirconia crowns? Achieve Durable, Aesthetic, and Biocompatible Dental Restorations

- What is the disadvantage of dental ceramic? Weighing Cost, Strength, and Aesthetics

- How do the rotational and orbital movements of the sample stage contribute to the uniformity of coatings on Zircaloy?

- Why is 700°C Pre-treatment Necessary for D2O Hydration on Ba0.95La0.05(Fe1-xYx)O3-δ? Ensuring Accurate Results

- What are the core process advantages of using a microwave reactor? Maximize Speed & Efficiency in Lab Characterization

- Why is vacuum distillation preferred for biodiesel ethanol removal? Protect Fuel Quality with Low-Temp Processing

- Why is a vacuum oven required during the preparation of Al-CNTs/h-BN composites? Prevent Defects & Ensure Purity

- How does oxygen flow at 2 to 8 SLPM regulate PS-PVD coating quality? Master Thermal Barrier Integrity