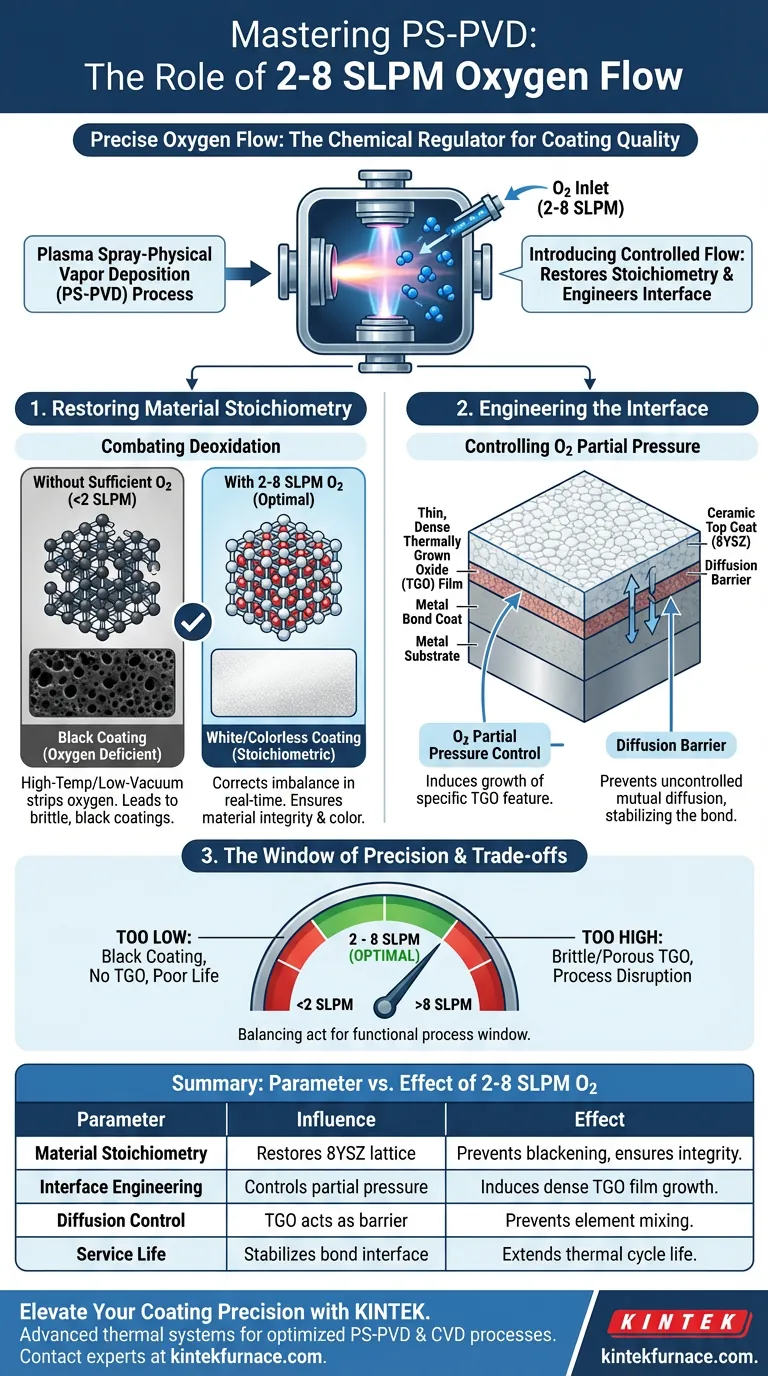

Introducing a controlled flow of oxygen at a rate of 2 to 8 SLPM during Plasma Spray-Physical Vapor Deposition (PS-PVD) acts as a precise chemical regulator for the coating system. This addition primarily restores the stoichiometry of ceramic materials like 8YSZ to prevent degradation and engineers a critical interface layer that significantly extends the lifespan of the thermal barrier coating.

High-temperature, low-pressure environments inherently strip oxygen from ceramic materials. Controlled oxygen introduction corrects this imbalance to maintain material integrity and induces a protective oxide film that acts as a barrier against coating failure.

Solving the Stoichiometry Challenge

Combating Deoxidation

In the PS-PVD process, the combination of high plasma temperatures and low vacuum pressure creates a reducing environment.

This environment aggressively strips oxygen atoms from the lattice of ceramic materials, such as 8YSZ (Yttria-Stabilized Zirconia).

Injecting oxygen at 2 to 8 SLPM compensates for these deoxidation-reduction reactions in real-time.

Visual Indicators of Quality

When oxygen levels drop too low during deposition, the ceramic coating physically changes.

The most obvious indicator of oxygen deficiency is the coating turning black.

By maintaining the flow within the specified range, the process ensures the ceramic retains its correct chemical composition and color, signaling a healthy, stoichiometric coating.

Engineering the Interface

Controlling Oxygen Partial Pressure

Beyond simply fixing the ceramic's color, the oxygen flow serves a deeper, structural purpose.

It allows operators to precisely manipulate the oxygen partial pressure within the deposition chamber.

This pressure is the control knob for chemical reactions occurring at the surface of the metal bonding layer.

The Role of the Thermally Grown Oxide (TGO)

The primary goal of adjusting partial pressure is to induce the growth of a specific feature: a Thermally Grown Oxide (TGO) film.

Under these controlled conditions, a thin and dense oxide layer forms on top of the metal bond coat.

Preventing Uncontrolled Diffusion

This induced TGO film serves as a critical diffusion barrier.

Without it, elements between the metal bond coat and the ceramic top coat would suffer from uncontrolled mutual diffusion.

By inhibiting this mixing, the TGO film stabilizes the interface, directly extending the thermal cycle life of the entire coating system.

Understanding the Trade-offs

The Window of Precision

The specified range of 2 to 8 SLPM is not arbitrary; it represents a functional process window.

Operating below this range risks insufficient re-oxidation, leading to substoichiometric (black) coatings and a lack of protective TGO formation.

Conversely, while not explicitly detailed in the reference, standard PVD principles suggest that excessive oxygen flow could disrupt the plasma plume or lead to excessive, brittle oxide growth. Adhering to the specific flow rate ensures the TGO remains thin and dense rather than thick and porous.

Making the Right Choice for Your Goal

To maximize the performance of your PS-PVD coatings, view oxygen flow as a tool for both material composition and interface engineering.

- If your primary focus is Material Integrity: Ensure flow rates are sufficient to prevent the "blackening" effect, confirming that the 8YSZ ceramic retains its stoichiometric structure.

- If your primary focus is Component Longevity: Prioritize precise pressure control to generate a continuous, dense TGO layer, as this is the primary mechanism for inhibiting diffusion and extending thermal cycle life.

Success in PS-PVD relies not just on depositing material, but on actively managing the chemical environment to build a robust, multi-layered system.

Summary Table:

| Parameter Influence | Effect of 2 - 8 SLPM Oxygen Flow |

|---|---|

| Material Stoichiometry | Restores oxygen lattice in 8YSZ; prevents ceramic blackening. |

| Interface Engineering | Controls partial pressure to induce a dense Thermally Grown Oxide (TGO) film. |

| Diffusion Control | TGO acts as a barrier, preventing uncontrolled mutual diffusion of elements. |

| Service Life | Extends thermal cycle life by stabilizing the ceramic-to-metal bond interface. |

Elevate Your Coating Precision with KINTEK

Are you looking to optimize your PS-PVD or CVD processes? KINTEK provides industry-leading high-temperature lab furnaces and customizable thermal systems designed to meet the rigorous demands of material science. Backed by expert R&D and manufacturing, our Muffle, Tube, Rotary, and Vacuum systems offer the precision control needed to manage oxygen partial pressures and material stoichiometry effectively.

Ready to enhance your lab’s efficiency and coating performance? Contact our technical experts today to find the perfect solution for your unique research and production needs.

Visual Guide

References

- He Qin, Xiaoming You. Investigation of the Interface Diffusion Layer’s Impact on the Thermal Cycle Life of PS-PVD Thermal Barrier Coatings. DOI: 10.3390/coatings15010013

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Spark Plasma Sintering SPS Furnace

People Also Ask

- How does a high-precision infrared temperature measurement system influence the sintering quality of Al2O3/TiC ceramics?

- How does a vacuum oven contribute to the performance of composite electrode slurries? Enhance Battery Life & Stability

- What is an industrial oven and which industries use it? Discover Versatile Thermal Processing Solutions

- What role does microwave heating equipment play in solder-free VIG? Boost Efficiency with Edge Fusion Technology

- What is the role of electric furnaces in the direct reduction of iron? Powering the Future of Green Metallurgy

- What is the function of a high-temperature sintering furnace in ceramic membrane production? Engineered Performance

- What are the advantages of Spark Plasma Sintering (SPS) for TiC alloys? Preserve Precision and Microstructure

- Why are DEZ and GEME selected for Ge:ZnO ALD? Unlock Precise Atomic Doping and Thermal Stability