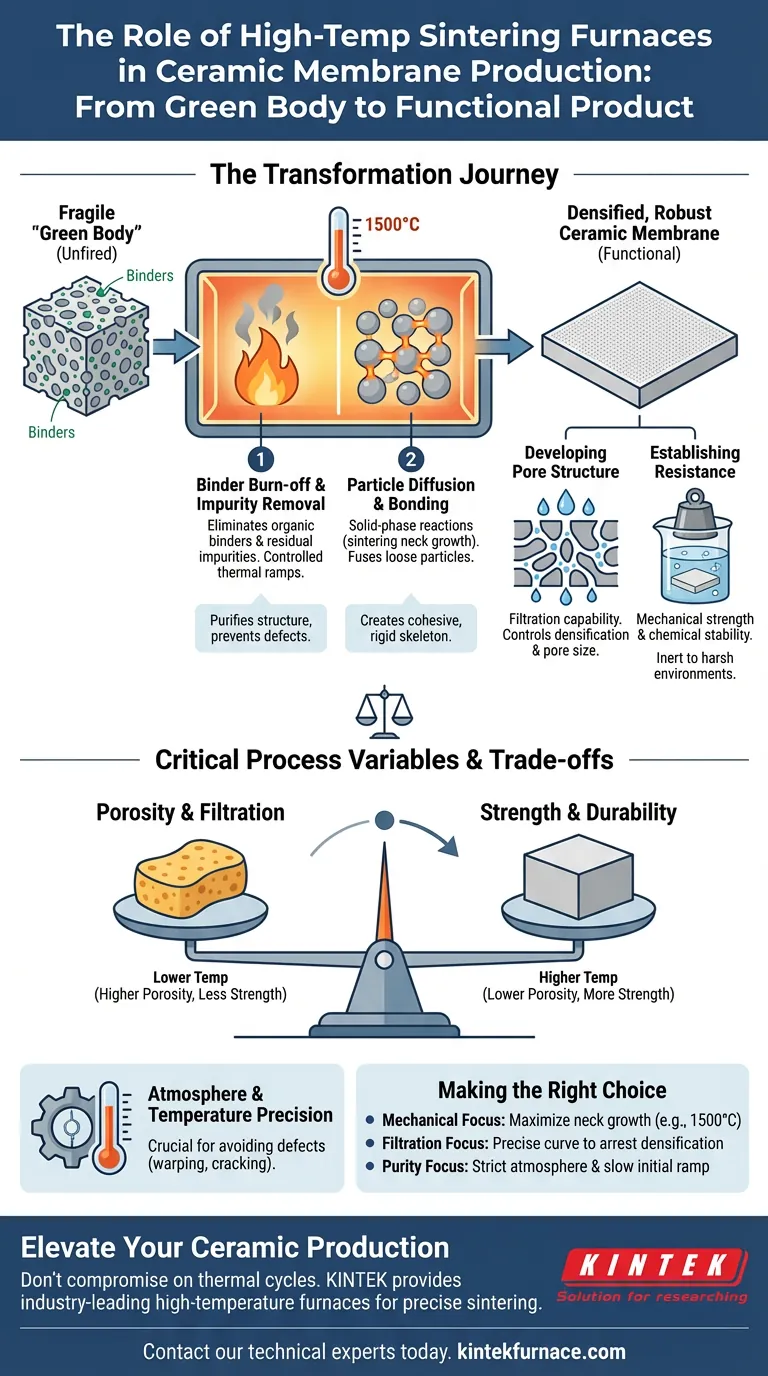

The high-temperature sintering furnace acts as the definitive transformation vessel in the final stage of ceramic membrane production. By executing precise heating curves and holding times, it first eliminates organic binders and residual impurities from the "green body." Subsequently, it drives the thermal diffusion and bonding of particles to convert a fragile compact into a densified, mechanically robust, and chemically resistant ceramic membrane.

Sintering is not merely a drying process; it is a complex physicochemical restructuring. The furnace provides the specific thermal energy required to fuse loose particles into a rigid skeleton, locking in the material's final porosity, mechanical durability, and chemical stability.

The Mechanics of Material Transformation

Removal of Impurities and Binders

Before the ceramic structure can harden, the furnace must purify the material. The initial heating stages utilize controlled thermal ramps to burn off organic binders used during the shaping process.

This phase effectively cleans the "green body" (the unfired ceramic). It ensures that no residual organics remain to compromise the structural integrity or chemical purity of the final membrane.

Particle Diffusion and Bonding

Once impurities are removed, the furnace creates the conditions for solid-phase reactions. As temperatures rise, the individual ceramic particles begin to diffuse and bond at their contact points.

This phenomenon, often referred to as sintering neck growth, is the physical bridge-building between particles. It transforms the loose powder compact into a cohesive, monolithic unit without melting the material entirely.

Defining Functional Properties

Developing the Pore Structure

The sintering furnace is responsible for establishing the membrane's filtration capability. By controlling the degree of densification, the furnace determines the final size and distribution of the pores.

This is a delicate transition from a loose powder arrangement to a dense ceramic skeleton containing a specific network of voids. The heat treatment solidifies this structure, ensuring the porosity remains stable during operation.

Establishing Mechanical and Chemical Resistance

The final stage of the heating curve locks in the membrane's physical properties. High temperatures (often ranging from 1100°C for kaolin to 1500°C for alumina) ensure the material achieves sufficient mechanical strength to withstand high pressures.

Simultaneously, this densification renders the membrane chemically inert. This resistance is vital for industrial applications where the membrane must survive exposure to harsh acids, bases, or solvents.

Critical Process Variables and Trade-offs

The Balance Between Porosity and Strength

There is an inherent trade-off in sintering: higher temperatures generally yield stronger materials but reduce porosity as the material becomes denser.

If the furnace temperature is too high, the pores may close completely, rendering the membrane useless for filtration. Conversely, if the temperature is too low, the membrane retains high porosity but lacks the structural integrity to survive operation.

Atmosphere and Temperature Precision

The furnace must maintain an extremely stable environment to prevent defects. Deviations in the heating curve or thermal uniformity can lead to warping, cracking, or inconsistent pore sizes across the membrane surface.

Furthermore, while many membranes are sintered in air, specific compositions may require controlled atmospheres (such as reducing gases) to ensure the correct chemical valence states. A failure to control the atmosphere can result in compromised chemical properties or phase impurities.

Making the Right Choice for Your Goal

The selection of sintering parameters depends entirely on the specific requirements of the final ceramic product.

- If your primary focus is mechanical durability: Prioritize higher sintering temperatures (e.g., 1500°C for alumina) to maximize sintering neck growth and structural rigidity.

- If your primary focus is filtration efficiency: Focus on precise control of the heating curve and holding times to arrest densification at the exact moment the desired pore structure is formed.

- If your primary focus is material purity: Ensure the furnace is capable of strict atmosphere control and utilizes a slow initial ramp rate to fully evacuate organic binders before densification begins.

The sintering furnace does not just heat the material; it engineers the final performance characteristics of the membrane through precise thermal control.

Summary Table:

| Stage of Sintering | Process Function | Impact on Ceramic Membrane |

|---|---|---|

| Binder Burn-off | Thermal decomposition of organics | Purifies the green body and prevents structural defects. |

| Particle Diffusion | Sintering neck growth (solid-phase) | Bonds loose particles into a cohesive, monolithic skeleton. |

| Densification | Controlled pore contraction | Finalizes mechanical strength, chemical resistance, and porosity. |

| Cooling/Stabilization | Controlled thermal ramp-down | Prevents cracking and locks in the final material properties. |

Elevate Your Ceramic Production with KINTEK Precision

Don't let inconsistent thermal cycles compromise your filtration performance. KINTEK provides industry-leading high-temperature furnaces (Muffle, Tube, Vacuum, and CVD systems) designed specifically for the rigorous demands of ceramic sintering.

Backed by expert R&D and manufacturing, our systems offer the precise heating curves and atmospheric control necessary to balance mechanical strength with perfect porosity. Whether you require a standard solution or a custom-engineered furnace for unique research needs, we deliver the reliability your laboratory deserves.

Ready to optimize your sintering process? Contact our technical experts today to find the perfect solution for your lab.

Visual Guide

References

- Rouzait Jarrar, Maryam Al‐Ejji. Environmental remediation and the efficacy of ceramic membranes in wastewater treatment—a review. DOI: 10.1007/s42247-024-00687-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does oxygen-enhanced alkaline thermal treatment benefit high-purity cellulose pulp? Achieve Superior Fiber Yield

- How is a vacuum impregnation system utilized during wood leaching resistance tests? Achieve Full Saturation for EN 84

- Why is high-performance high-temperature heat treatment equipment essential for the 900°C calcination of copper oxide?

- What is the design focus of a thermal reactor in flash pyrolysis? Optimize Bio-oil Yield with Precision Engineering

- What key process environments does a Molecular Beam Epitaxy (MBE) system provide? Optimize CaF2 Thin Film Growth

- What is the primary role of a vacuum drying oven in WO3 nanostructure preparation? Achieve Perfect Morphology

- What role does an infrared image furnace play in the Floating Zone Method? Mastering Nb-doped beta-Ga2O3 Crystal Growth

- Why must raw kaolin undergo heat treatment for DLP 3D printing? Control Viscosity for Precision Printing