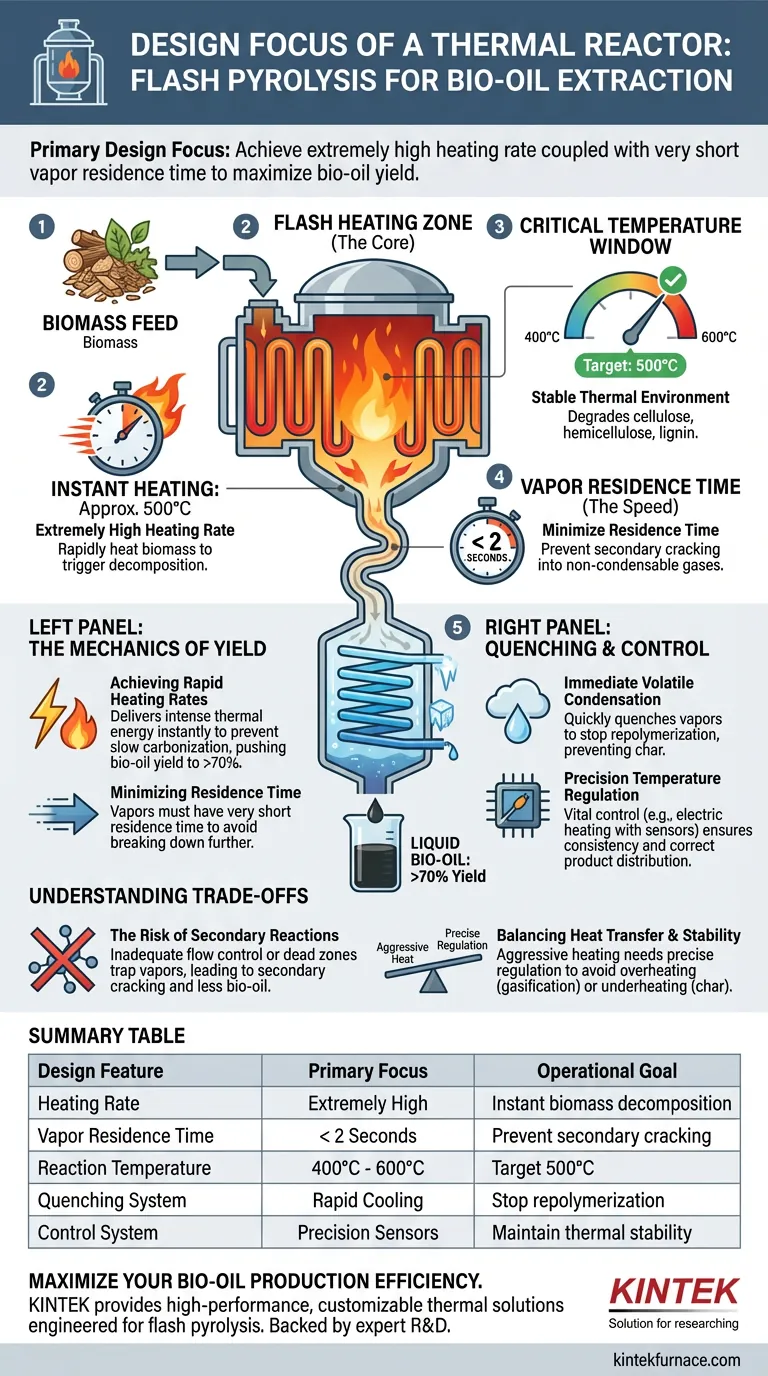

The primary design focus of a thermal reactor in flash pyrolysis is achieving an extremely high heating rate coupled with a very short vapor residence time. The system is engineered to rapidly heat biomass to approximately 500°C in an oxygen-free environment, maximizing bio-oil production by minimizing the time vapors spend at high temperatures.

To extract maximum bio-oil, the reactor must function as a precision timing instrument. It must heat biomass instantly to trigger decomposition and then immediately cool the vapors to prevent them from degrading into gas or char.

The Mechanics of Maximizing Yield

Achieving Rapid Heating Rates

The fundamental goal of flash pyrolysis is to convert biomass into vapor before it has time to form char.

To do this, the reactor must deliver intense thermal energy instantly. This rapid heating prevents the biomass from slowly carbonizing, pushing the yield of bio-oil to typically reach more than 70% of the biomass mass.

Minimizing Residence Time

Once the biomass turns to vapor, speed becomes critical.

The design must ensure these vapors have a very short residence time inside the hot zone. If vapors linger too long, they undergo secondary cracking, breaking down further into non-condensable gases rather than the desired oil.

The Critical Temperature Window

While speed is the driver, temperature is the steering wheel.

The reactor is designed to maintain a stable thermal environment, ideally around 500°C. According to supplementary data, this window generally spans between 400°C and 600°C, serving as the energy foundation for degrading cellulose, hemicellulose, and lignin.

The Role of Quenching and Control

Immediate Volatile Condensation

Heating is only half the design equation; the system must also be equipped with a high-efficiency cooling system.

The reactor design must facilitate the immediate transfer of hot volatiles to a condenser. Quickly quenching these vapors stops repolymerization reactions, locking the chemical structure into a liquid bio-oil state rather than allowing it to revert to char.

Precision Temperature Regulation

Modern reactors often utilize electric heating systems equipped with thermocouple sensors to ensure consistency.

Precise temperature control is vital because it directly determines the final product distribution. A fluctuation of just a few degrees can shift the output balance significantly between bio-oil, bio-char, and syngas.

Understanding the Trade-offs

The Risk of Secondary Reactions

The greatest design pitfall in flash pyrolysis is inadequate flow control.

If the reactor design allows "dead zones" where vapors get trapped, or if the cooling system is undersized, secondary cracking is inevitable. This drastically reduces bio-oil yield and increases the production of low-value gases.

Balancing Heat Transfer and Stability

Achieving extremely high heating rates requires aggressive energy input, which can be difficult to control.

If the heating is too aggressive without precise regulation, you risk overheating the biomass (leading to gasification). Conversely, if the heating is too conservative to maintain stability, you risk incomplete decomposition (leading to char).

Making the Right Choice for Your Goal

To optimize your reactor design for specific outcomes, consider the following parameters:

- If your primary focus is Maximum Bio-oil Yield: Prioritize a design that ensures the fastest possible transit time from the heat source to the condensation unit to prevent secondary cracking.

- If your primary focus is Product Consistency: Invest heavily in the temperature control system (sensors and modulation) to maintain the reaction strict at 500°C.

Success in flash pyrolysis is ultimately defined by how tightly you can control the milliseconds between heating and cooling.

Summary Table:

| Design Feature | Primary Focus | Operational Goal |

|---|---|---|

| Heating Rate | Extremely High | Instant biomass decomposition to avoid char formation |

| Vapor Residence Time | < 2 Seconds | Prevent secondary cracking into non-condensable gases |

| Reaction Temperature | 400°C - 600°C | Target 500°C for optimal cellulose and lignin degradation |

| Quenching System | Rapid Cooling | Stop repolymerization to lock volatiles into liquid state |

| Control System | Precision Sensors | Maintain thermal stability for consistent product distribution |

Maximize Your Bio-Oil Production Efficiency

Transitioning from lab-scale research to industrial-grade pyrolysis requires thermal equipment that offers absolute control over milliseconds and degrees. KINTEK provides high-performance, customizable thermal solutions—including Muffle, Tube, and Vacuum furnace systems—engineered specifically to meet the rigorous demands of flash pyrolysis and bio-energy research.

Backed by expert R&D and manufacturing, our systems ensure the rapid heating and precise temperature regulation necessary to prevent secondary cracking and maximize your yield. Partner with KINTEK today for your custom laboratory heating needs!

Visual Guide

References

- Nancy Jan Sliper. Energy Utilization and Conversion in Modern Biomass Conversion Technologies. DOI: 10.53759/832x/jcims202402001

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does a gas evolution analysis system monitor gas release? Optimize Your Casting Integrity

- What is the function of zone melting purification equipment in the preparation of CsPbBr3 perovskite single crystals? Key for 6N.

- Why maintain argon and oxygen control in Titanium LMD? Ensure Peak Purity for Your High-Performance Components

- Flash Pyrolyser vs. TGA: Which is Best for Assessing RDF as a Blast Furnace Reducing Agent?

- What are the advantages of using a vacuum drying oven for MnMgPO4@C3N4? Preserving Photocatalyst Integrity

- Why is electromagnetic stirring technology employed during the melting process of Titanium-Copper (Ti–Cu) alloys?

- Why is the addition of silver nanoparticles critical for Ag2Se films? Unlock High Thermoelectric Performance

- Why is industrial-grade isostatic pressing necessary for zirconia? Achieve Uniform Density & Structural Integrity