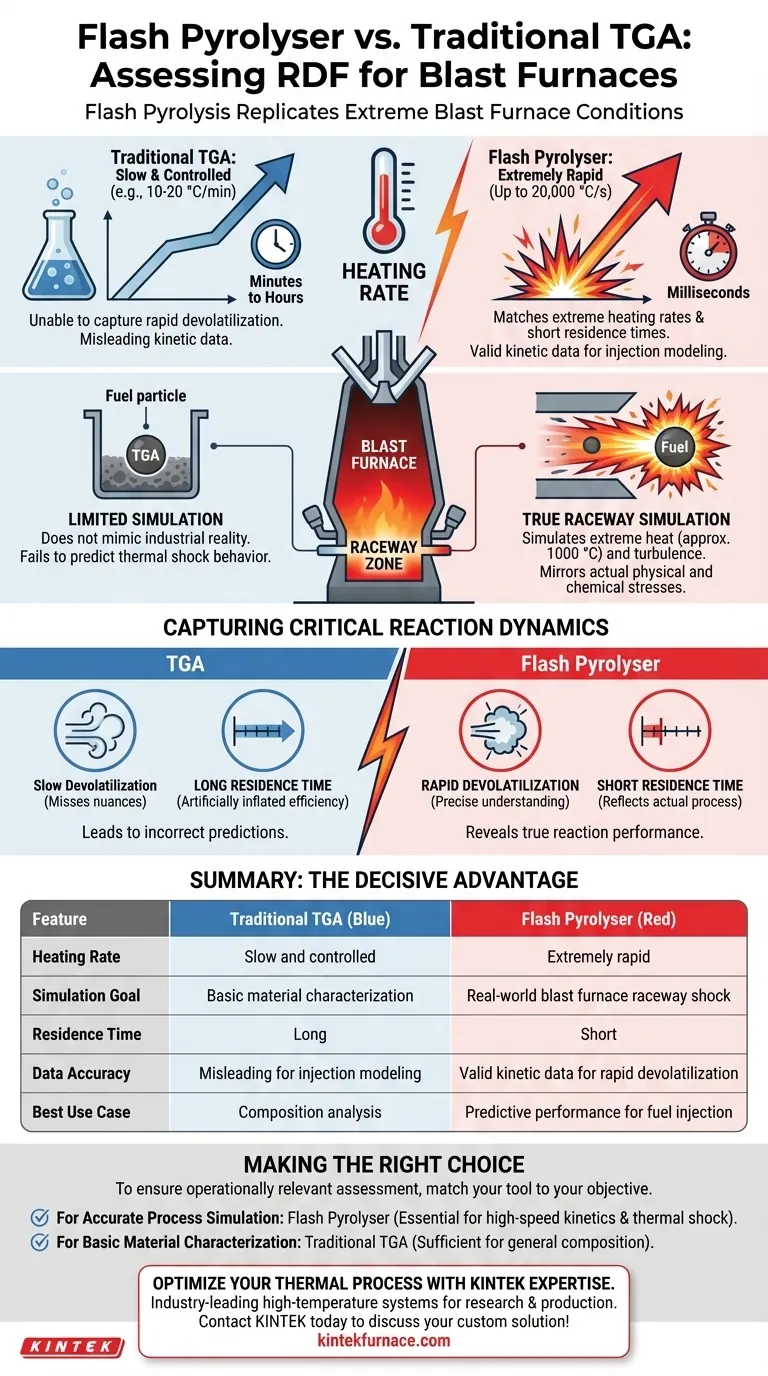

The decisive advantage of a Flash Pyrolyser over a traditional Thermogravimetric Analyzer (TGA) is its ability to replicate the violent, high-velocity thermal conditions of a blast furnace. While TGA provides data based on slow, controlled heating, a Flash Pyrolyser can achieve heating rates of up to 20,000 °C/s, accurately simulating the thermal shock Refuse Derived Fuel (RDF) experiences during injection.

The core limitation of traditional TGA is its inability to capture the rapid devolatilization that occurs in a blast furnace. Flash Pyrolysis solves this by matching the extreme heating rates and short residence times of the raceway, providing the only valid kinetic data for injection modeling.

Simulating the Blast Furnace Reality

The Disconnect in Heating Rates

To assess RDF as a reducing agent effectively, your testing equipment must match the process environment.

Traditional TGA operates at relatively slow heating rates. This approach allows for careful mass loss measurement but fails to mimic the industrial reality of a blast furnace.

In contrast, a Flash Pyrolyser offers heating rates up to 20,000 °C/s. This capability is essential because measuring how a material behaves during slow heating does not predict how it will behave under instant thermal shock.

Replicating Raceway Conditions

When RDF is injected into a blast furnace, it enters the "raceway"—a zone characterized by extreme heat and turbulence.

The Flash Pyrolyser is designed to simulate this specific thermochemical environment, which creates temperatures around 1000 °C.

By mirroring these conditions, the equipment ensures that the data collected reflects the actual physical and chemical stresses the fuel will encounter.

Capturing Critical Reaction Dynamics

Rapid Devolatilization

The speed at which volatile matter is released (devolatilization) changes drastically based on how fast the material is heated.

Because TGA heats slowly, it often misses the nuances of rapid devolatilization. This is the explosive release of gases that happens the moment fuel hits the raceway.

Flash Pyrolysis captures this rapid phase, providing a precise understanding of how non-fossil fuel carbon decomposes in milliseconds rather than minutes.

Importance of Residence Time

In a blast furnace injection scenario, fuel has a very short "residence time" to react before it moves through the furnace or is consumed.

Traditional TGA extends the reaction over a long period, which can artificially inflate the perceived reaction efficiency.

Flash Pyrolyser data reflects the short residence times of the actual process, revealing whether the RDF will fully devolatilize and react within the tight time constraints of the operation.

The Pitfall of Standard TGA Analysis

Misleading Kinetic Data

Using TGA data to model blast furnace injection introduces a significant margin of error.

The data derived from slow heating suggests a reaction pathway that simply does not exist inside a blast furnace raceway.

Relying on this "slow" data for "fast" process modeling can lead to incorrect predictions regarding fuel efficiency, reducing agent potential, and overall furnace stability.

Making the Right Choice for Your Goal

To ensure your assessment of RDF is operationally relevant, match your tool to your specific engineering objective:

- If your primary focus is accurate process simulation: You must use a Flash Pyrolyser to capture the high-speed kinetics and thermal shock inherent to the blast furnace raceway.

- If your primary focus is basic material characterization: Traditional TGA may suffice for general composition analysis, but it should not be used to predict injection performance.

Accurate assessment relies not just on analyzing the fuel, but on analyzing it under the conditions it is destined to endure.

Summary Table:

| Feature | Traditional TGA | Flash Pyrolyser |

|---|---|---|

| Heating Rate | Slow and controlled | Extremely rapid (Up to 20,000 °C/s) |

| Simulation Goal | Basic material characterization | Real-world blast furnace raceway shock |

| Residence Time | Long (Minutes to Hours) | Short (Milliseconds) |

| Data Accuracy | Misleading for injection modeling | Valid kinetic data for rapid devolatilization |

| Best Use Case | Composition analysis | Predictive performance for fuel injection |

Optimize Your Thermal Process with KINTEK Expertise

Don't let inaccurate data compromise your furnace efficiency. KINTEK provides industry-leading laboratory high-temperature systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—designed to meet the most rigorous research and production demands.

Backed by expert R&D and precision manufacturing, our equipment is fully customizable to solve your unique material challenges. Whether you are analyzing RDF performance or developing new non-fossil fuel applications, our team is ready to provide the specialized tools you need for success.

Ready to elevate your lab's capabilities? Contact KINTEK today to discuss your custom solution!

Visual Guide

References

- Eurig W. Jones, Peter J. Holliman. Pyrolysis-GCMS of Plastic and Paper Waste as Alternative Blast Furnace Reductants. DOI: 10.3390/chemengineering9010015

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why maintain argon and oxygen control in Titanium LMD? Ensure Peak Purity for Your High-Performance Components

- Why is a high-precision heating/cooling stage important for 2D In2Se3 studies? Secure Precise Phase Transition Data

- Why is vacuum impregnation necessary for PAN-GF electrodes? Ensure Peak Fiber Conductivity and Slurry Integration

- What role does a laboratory oven play in the drying phase of Co–Mg catalyst precursors? Ensuring Component Uniformity

- Why are temperature control and pressure critical for V-NbOPO4@rGO electrode sheets? Optimize Your Battery Performance

- How do stirring equipment and temperature-controlled heating stages influence magnetic nanoparticle quality?

- What is the purpose of adding phosphorus pentoxide (P2O5) as a desiccant? Ensure Deep Electrolyte Regeneration

- What are the advantages of using multi-stage laboratory sintering furnaces? Ensure Defect-Free Powder Metallurgy