Titanium alloys possess high chemical reactivity at elevated temperatures, making strict environmental control a critical requirement during Laser Melting Deposition (LMD). You must maintain a high-purity argon atmosphere with oxygen levels specifically controlled below 50 ppm to prevent the material from reacting with oxygen and nitrogen. Failure to maintain this environment leads to immediate oxidation, which compromises the material's purity and structural integrity.

The primary function of the high-purity argon environment is to shield the titanium melt pool from atmospheric contamination. By capping oxygen content at 50 ppm, you prevent the formation of brittle oxides, ensuring ductility and facilitating strong metallurgical bonding between deposited layers.

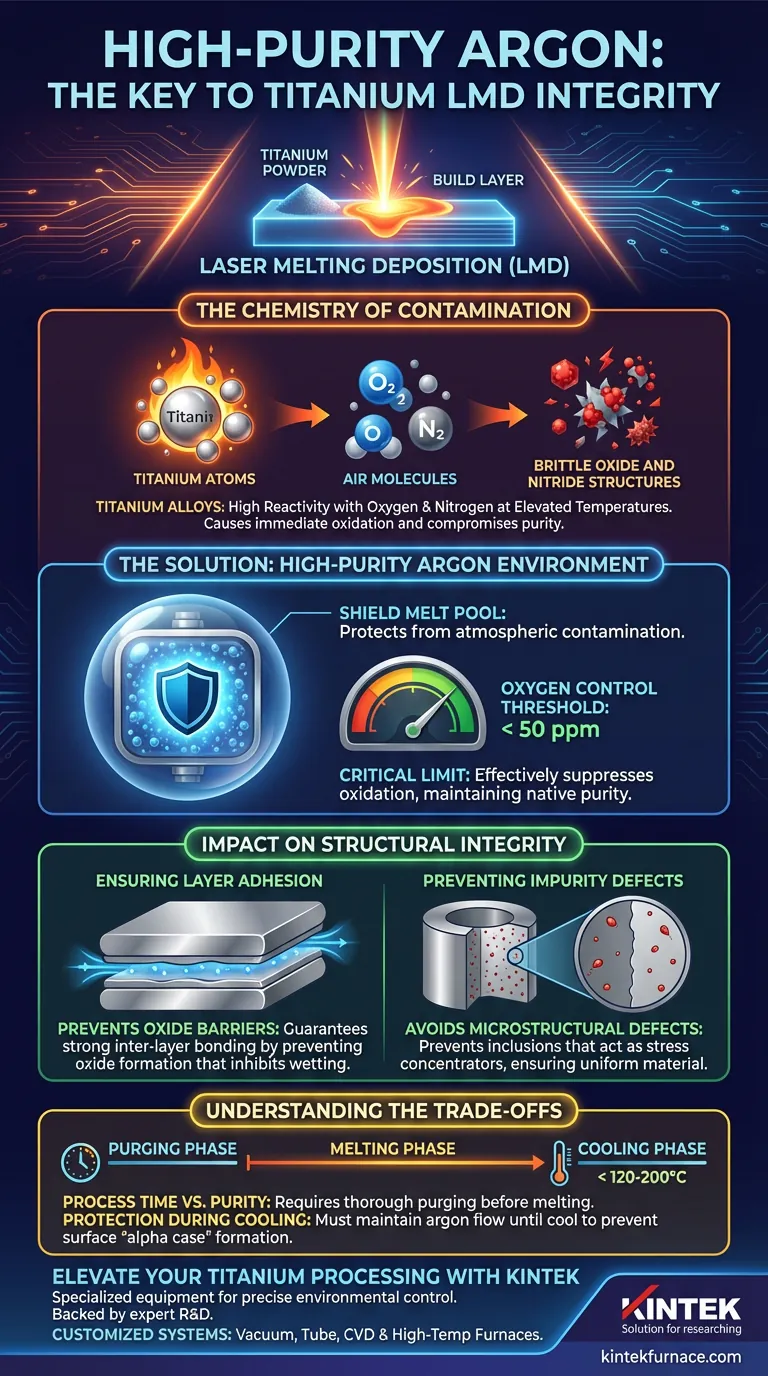

The Chemistry of Contamination

High-Temperature Reactivity

Titanium is notorious for its affinity for oxygen and nitrogen. When titanium alloys are heated to the melting point during LMD, they react easily with these atmospheric gases.

Without a protective barrier, the metal absorbs these elements rapidly. This reaction fundamentally alters the alloy's chemistry, leading to the formation of oxides and nitrides that degrade the material's intended properties.

The 50 ppm Threshold

To mitigate this risk, the processing chamber requires an atmosphere of high-purity argon.

The primary reference explicitly states that controlling the oxygen content below 50 ppm is essential. This specific threshold is the boundary required to effectively suppress oxidation and maintain the native purity of the titanium alloy.

Impact on Structural Integrity

Ensuring Layer Adhesion

LMD is a layer-by-layer additive process. The success of the build depends entirely on the fusion between the newly deposited material and the previous layer.

If oxidation occurs, an oxide layer forms on the surface of the solidified metal. This oxide layer acts as a barrier, preventing the next layer of molten titanium from wetting and bonding effectively with the substrate. Strict argon control ensures these oxide barriers do not form, guaranteeing strong inter-layer bonding.

Preventing Impurity Defects

Oxidation does more than just affect the surface; it introduces impurity defects within the bulk material.

These inclusions can act as stress concentrators, leading to premature failure of the part. By maintaining a pristine argon environment, you avoid these microstructural defects, ensuring the final component is uniform and reliable.

Understanding the Trade-offs

Process Time vs. Purity

Achieving this level of purity is not instantaneous. The chamber must be purged—often multiple times—to eliminate residual air and moisture before melting begins.

Rushing this purging stage to save time is a common pitfall. If melting starts before the atmosphere is fully stabilized below 50 ppm, the initial layers will be compromised, potentially ruining the entire build.

Protection During Cooling

The need for protection extends beyond the melting phase. The material remains reactive even as it solidifies and cools.

As noted in supplementary contexts regarding reactive metals, the protective gas flow must often be maintained until the part has cooled significantly (e.g., below 200°C or even 120°C). Cutting the argon flow too early exposes the hot metal to air, causing surface oxidation and "alpha case" formation that requires expensive post-processing to remove.

Making the Right Choice for Your Project

To maximize the quality of your titanium LMD components, align your environmental controls with your specific engineering goals:

- If your primary focus is Structural Durability: rigorous adherence to the <50 ppm oxygen limit is required to prevent oxide inclusions that create weak points in the metal.

- If your primary focus is Material Ductility: ensure the argon protection extends through the cooling phase to prevent surface embrittlement caused by interstitial element absorption.

By treating the argon environment as a critical process parameter rather than a secondary utility, you ensure the integrity of your titanium components.

Summary Table:

| Factor | Requirement | Impact of Failure |

|---|---|---|

| Atmosphere | High-Purity Argon | Chemical contamination and alloy alteration |

| Oxygen Limit | < 50 ppm | Formation of brittle oxides and nitrides |

| Layer Bonding | Oxide-Free Surface | Poor wetting and weak metallurgical bonding |

| Cooling Phase | Protected < 120-200°C | "Alpha case" formation and surface embrittlement |

Elevate Your Titanium Processing with KINTEK

Don't let atmospheric contamination compromise your advanced additive manufacturing. KINTEK provides the specialized equipment needed to maintain precise environmental control for reactive metals.

Backed by expert R&D and manufacturing, we offer customized Vacuum, Tube, and CVD systems, along with other lab high-temperature furnaces designed specifically for high-purity environments. Ensure your components meet the strictest structural and chemical standards.

Contact KINTEK experts today to find your solution

Visual Guide

References

- Jianhua Sun, Zhonggang Sun. Ti6Al4V-0.72H on the Establishment of Flow Behavior and the Analysis of Hot Processing Maps. DOI: 10.3390/cryst14040345

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- Why is 600 °C critical for ZIF-8 carbonization? Achieve Optimal Surface Area and Functional Group Retention

- What is the purpose of performing a quenching treatment? Optimize Doped Alkali Halide Crystal Spectral Analysis

- Why is a constant-temperature blast drying oven necessary for processing biomass precursors? Ensure Structural Integrity

- What is the core role of a Bridgman furnace in single crystal superalloy production? Mastering Thermal Gradients

- Why is an industrial electric furnace with precise cooling control necessary in lead-bismuth alloy enrichment?

- What is the function of a forced drying oven in SiOC coating conversion? Ensure Flawless Solvent Removal

- What is the function of a flash furnace in sludge treatment? Essential Thermal Preparation for Phosphorus Recovery

- What role does microwave heating equipment play in solder-free VIG? Boost Efficiency with Edge Fusion Technology