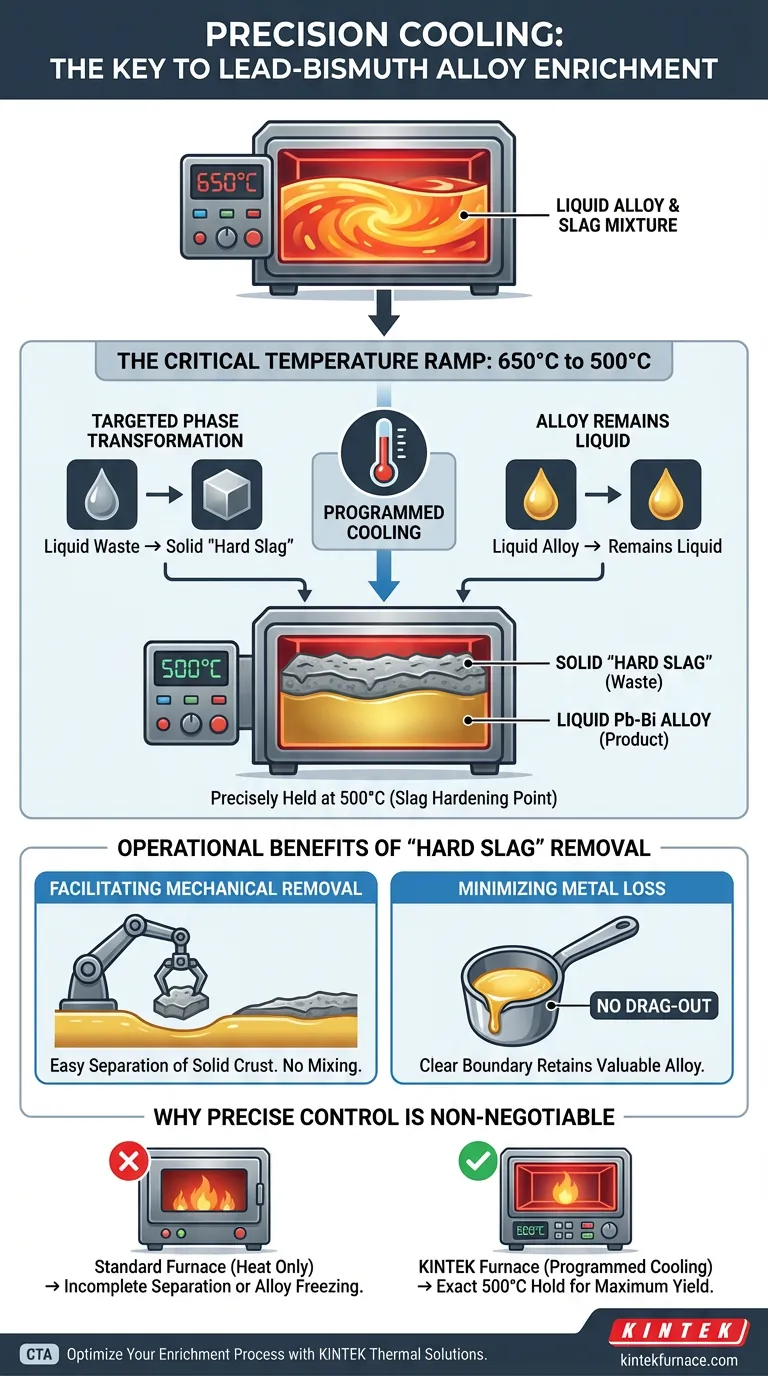

Precise thermal management is the key to efficient impurity separation. An industrial electric furnace is necessary in the final enrichment stage to execute a specific, programmed temperature drop from 650°C to 500°C. This controlled cooling solidifies the waste slag while keeping the lead-bismuth alloy liquid, enabling clean physical separation.

By utilizing programmed cooling to induce a selective phase change, the furnace transforms liquid contaminants into a solid crust that can be easily removed without sacrificing the valuable liquid metal alloy.

The Mechanics of Selective Solidification

Targeted Phase Transformation

The primary function of the furnace in this stage is not heating, but programmed cooling.

The goal is to force a physical state change in the lead metaborate slag. By lowering the temperature, you cause this specific waste material to transition from a liquid state into a solid "hard slag."

The Critical Temperature Window

Success depends on a precise descent from 650°C down to 500°C.

The furnace must control this ramp and hold the temperature at 500°C. This is the "slag hardening temperature," the specific point where the waste solidifies but the lead-bismuth alloy remains in a liquid state.

Operational Benefits of Hard Slag Removal

Facilitating Mechanical Removal

When slag is in a liquid state, it is difficult to distinguish and separate from the liquid metal.

Once the furnace cools the mixture to 500°C, the slag forms a solid crust. This allows for straightforward mechanical removal of the impurities from the surface of the liquid metal.

Minimizing Metal Loss

Attempting to clean liquid slag often results in "drag-out," where valuable alloy is accidentally removed along with the waste.

Solidifying the slag creates a clear boundary between waste and product. This significantly reduces metal loss, ensuring that the maximum amount of enriched lead-bismuth is retained during the cleaning process.

Understanding the Trade-offs

The Necessity of Advanced Control

A standard furnace that only provides heat is insufficient for this process.

The equipment must be capable of active or programmed cooling. This requirement likely increases equipment complexity or cost compared to simple heating units, as it requires precise modulation of temperature decreases.

Precision is Non-Negotiable

There is very little margin for error in this thermal window.

If the furnace fails to cool to exactly 500°C, the slag will remain liquid, preventing separation. Conversely, overcooling could risk solidifying the alloy itself, halting the process entirely.

Optimizing High-Purity Enrichment

To ensure the highest efficiency in your lead-bismuth enrichment process, consider the following:

- If your primary focus is Material Yield: Ensure your furnace controls are calibrated to hold exactly at 500°C to create a distinct solid slag crust, preventing the accidental removal of liquid alloy.

- If your primary focus is Process Speed: Utilize equipment with automated cooling profiles to transition from 650°C to 500°C as rapidly as the material properties allow.

By leveraging precise temperature control to induce phase changes, you transform a complex purification challenge into a straightforward mechanical task.

Summary Table:

| Process Feature | Temperature/Action | Benefit to Enrichment |

|---|---|---|

| Starting Point | 650°C (Liquid State) | Complete melting of alloy and slag mixture |

| Cooling Target | 500°C (Hold Point) | Solidifies 'hard slag' while metal remains liquid |

| Separation Method | Mechanical Removal | Easy extraction of solid crust from liquid metal surface |

| Yield Optimization | Phase Control | Minimizes metal 'drag-out' and reduces material loss |

Optimize Your Enrichment Process with KINTEK

Precision is non-negotiable when separating high-value alloys from waste. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, engineered for the rigorous demands of lead-bismuth enrichment.

Backed by expert R&D and manufacturing, our furnaces offer the advanced programmed cooling and thermal stability required to hit the critical 500°C slag-hardening window every time. Whether you need a standard setup or a fully customizable high-temp furnace tailored to your unique metallurgy, KINTEK ensures maximum material yield and process efficiency.

Ready to minimize metal loss and streamline your purification?

Contact KINTEK experts today for a custom consultation

Visual Guide

References

- Investigation of the Process of Increasing Bismuth Content in Lead Alloys Using the Oxygen Oxidation Method. DOI: 10.3390/pr13051276

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- How do precision temperature-controlled ovens function for SiC-Ti3SiC2 preform curing? Expert Thermal Control Guide

- How does a needle valve control silver foil surface quality for graphene growth? Prevent defects with pressure control.

- What role does a Teflon-lined stainless steel autoclave play in the hydrothermal synthesis of PtLaOx@S-1 catalysts?

- What is the purpose of the two-step heat treatment process? Optimize Zirconolite-Based Glass-Ceramic Matrices

- What is the primary function of a batch fixed bed reactor in the slow pyrolysis of teff husk? Maximize Biochar Yield

- Why is a constant temperature water bath or hot plate required for MXene post-treatment? Master Precise Delamination

- Why is a vacuum freeze dryer used for Vivianite? Optimize Your LFP Synthesis with Superior Precursor Integrity