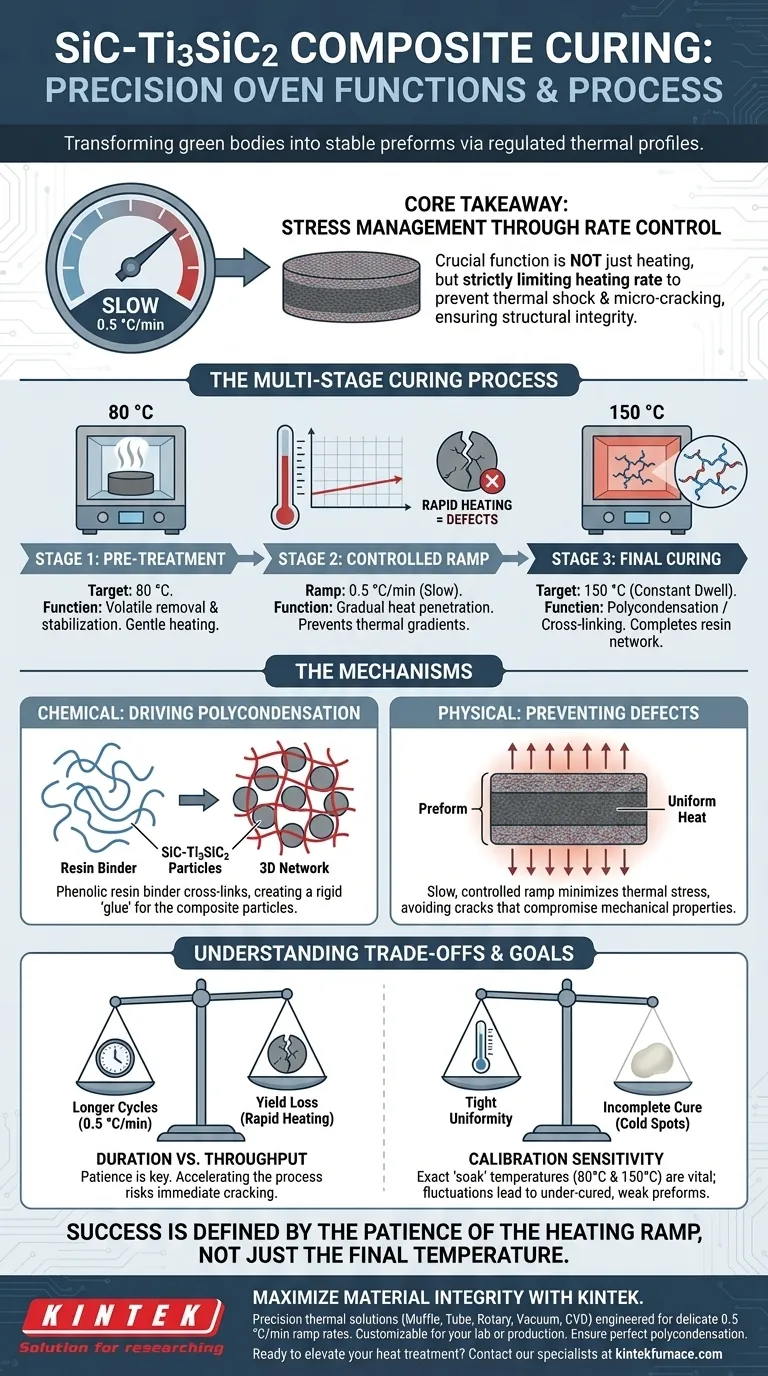

Precision temperature-controlled ovens function by executing a strictly regulated, multi-stage thermal profile designed to polymerize the binder within the composite preform. By maintaining specific setpoints—typically a pre-treatment at 80 °C followed by a constant-temperature cure at 150 °C—these furnaces drive the polycondensation of phenolic resin to create a rigid, three-dimensional network.

Core Takeaway The critical function of these devices is not merely heating, but stress management through rate control. By strictly limiting the heating rate (e.g., 0.5 °C/min), the equipment prevents thermal shock and micro-cracking, ensuring the SiC-C preform retains the structural integrity required for subsequent high-temperature processing.

The Mechanics of the Curing Process

The curing stage is the foundational step where the "green" body is transformed into a stable preform. Precision ovens manage this through two primary mechanisms.

Driving Polycondensation

The primary chemical goal of this stage is polycondensation. The oven heats the phenolic resin binder to initiate a reaction that cross-links the polymer chains.

This transforms the loose resin into a robust three-dimensional network. This network acts as the structural "glue" that holds the Silicon Carbide (SiC) and Titanium Silicon Carbide (Ti3SiC2) particles together.

Multi-Stage Temperature Targets

Precision heating does not simply ramp to a final temperature; it utilizes distinct plateaus to ensure uniform transformation.

A common protocol involves a pre-treatment stage at 80 °C, likely intended to stabilize the material or remove volatiles gently. This is followed by a constant-temperature curing stage at 150 °C, which completes the resin cross-linking.

Managing Thermal Stress

Beyond chemistry, the physical integrity of the preform is dictated by how heat is applied over time.

Controlled Heating Rates

The speed at which temperature increases is as critical as the target temperature itself. High-precision furnaces are programmed with a slow, specific heating rate, such as 0.5 °C/min.

Preventing Structural Defects

Rapid heating creates thermal gradients, where the outside of the preform expands or cures faster than the inside.

By utilizing a slow, controlled ramp, the oven allows heat to penetrate the preform evenly. This minimizes thermal stress, effectively preventing the formation of cracks that would compromise the mechanical properties of the final SiC-C preform.

Understanding the Trade-offs

While precision curing is essential for quality, it presents specific operational challenges that must be balanced.

Process Duration vs. Throughput

The strict adherence to a 0.5 °C/min ramp rate significantly extends the cycle time. A full curing cycle can take many hours to reach 150 °C and hold there.

Attempts to accelerate this process to increase manufacturing throughput often result in immediate yield losses due to cracking.

Sensitivity to Equipment Calibration

Because the process relies on exact "soak" temperatures (80 °C and 150 °C), the equipment must have tight uniformity tolerances.

Fluctuations or cold spots in the oven can lead to incomplete polycondensation. An under-cured preform will lack the necessary strength and may fail during subsequent handling or high-temperature sintering.

Making the Right Choice for Your Goal

The curing stage sets the baseline quality for the entire composite. Your approach to programming the furnace should depend on your specific priorities.

- If your primary focus is Structural Integrity: Adhere strictly to the 0.5 °C/min heating rate to eliminate thermal gradients and prevent micro-cracking.

- If your primary focus is Chemical Stability: Ensure the dwell time at 150 °C is sufficient to fully complete the polycondensation reaction, leaving no uncured resin.

Success in fabricating SiC-Ti3SiC2 preforms is defined by the patience of the heating ramp, not just the final temperature.

Summary Table:

| Stage | Target Temperature | Primary Function | Control Parameter |

|---|---|---|---|

| Pre-treatment | 80 °C | Volatile removal & stabilization | Precise Setpoint |

| Curing Ramp | Up to 150 °C | Gradual heat penetration | 0.5 °C/min (Slow Ramp) |

| Final Curing | 150 °C | Resin polycondensation/Cross-linking | Constant Dwell Time |

| Stress Management | Variable | Prevent micro-cracking | Uniform Heat Distribution |

Maximize Your Material Integrity with KINTEK

Precision is the difference between a high-performance composite and a failed preform. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, specifically engineered to handle the delicate 0.5 °C/min ramp rates required for advanced ceramics.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique lab or production needs. Ensure perfect polycondensation and eliminate thermal stress in your SiC-Ti3SiC2 projects today.

Ready to elevate your heat treatment process?

Contact our specialists now to find your custom furnace solution.

Visual Guide

References

- Mingjun Zhang, Bo Wang. Electromagnetic Interference Shielding Effectiveness of Pure SiC–Ti3SiC2 Composites Fabricated by Reactive Melt Infiltration. DOI: 10.3390/ma18010157

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is the role of temperature control in MCM-41 synthesis? Master Precision Pore Engineering

- Why is precision drying equipment necessary for porous mullite ceramic skeletons? Prevent Cracks & Ensure Integrity

- How does a temperature-controlled heating chamber ensure AEMWE testing accuracy? Unlock Reliable Electrolyzer Data

- What is the function of industrial furnaces in 7075 aluminum solution treatment? Master Material Strength

- How does a rotating substrate holder contribute to the quality of CuGaO2 thin films? Achieve Uniformity in Sputtering

- Why is long-term NaOH immersion required for porous carbon? Optimize Your Template Removal & Surface Area

- How does a high-temperature laboratory furnace contribute to the formation of high-quality CsV3Sb5 single crystals?

- What are the advantages of PVD equipment for solar absorber films? Achieve Nanometer Precision and Maximum Efficiency