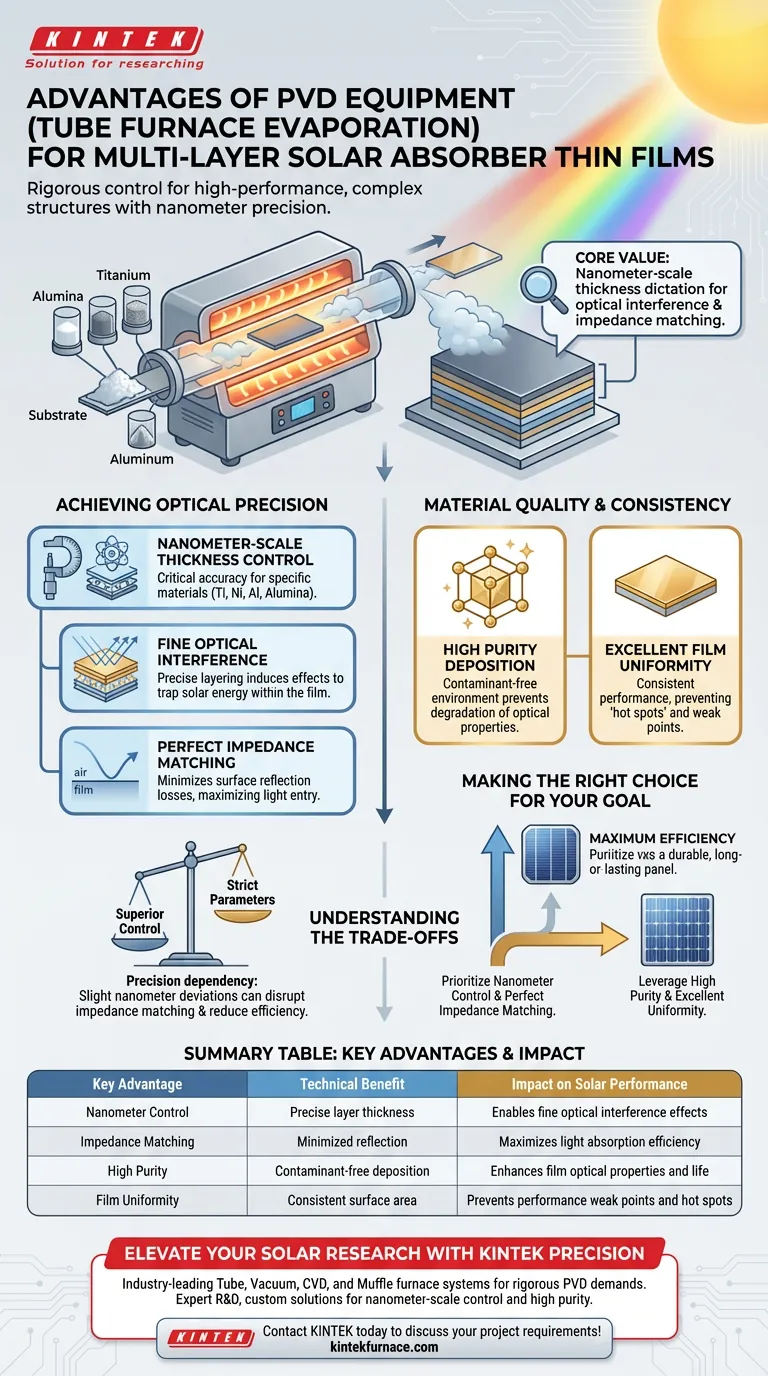

Physical vapor deposition (PVD) equipment, particularly tube furnace evaporation systems, provides the rigorous control necessary for fabricating high-performance solar absorber thin films. By delivering high purity and excellent film uniformity, these systems allow engineers to construct complex multi-layer structures using materials such as alumina, titanium, nickel, and aluminum with high precision.

The core value of this technology is its ability to dictate film thickness at the nanometer scale, which is the absolute prerequisite for creating fine optical interference effects and perfect impedance matching.

Achieving Optical Precision

Nanometer-Scale Thickness Control

The primary advantage of tube furnace evaporation systems is the ability to deposit layers with nanometer-level accuracy. This precision is critical when working with specific absorber materials like titanium, nickel, aluminum, and alumina.

Fine Optical Interference

Controlling thickness is not merely about structural dimensions; it is about manipulating light. Precise layering is required to induce specific optical interference effects that trap solar energy within the film.

Perfect Impedance Matching

To maximize absorption, the solar film must minimize reflection losses at the surface. PVD equipment enables the creation of structures that achieve perfect impedance matching, ensuring the maximum amount of light enters the absorber rather than bouncing off it.

Material Quality and Consistency

High Purity Deposition

Impurities in a thin film can degrade its optical properties and overall efficiency. PVD systems are designed to maintain high purity environments, ensuring that the deposited layers are free from contaminants that could hinder electron flow or light absorption.

Excellent Film Uniformity

Solar absorbers require consistent performance across the entire surface area of the device. Tube furnace evaporation systems deliver excellent film uniformity, preventing "hot spots" or weak points that can occur with less precise deposition methods.

Understanding the Trade-offs

The Necessity of Strict Parameters

While PVD systems offer superior control, this precision introduces a dependency on rigorous process parameters. Achieving the fine optical interference effects mentioned requires that the equipment be calibrated perfectly; even slight deviations in the nanometer scale can disrupt the impedance matching, significantly reducing the solar absorber's efficiency.

Making the Right Choice for Your Goal

To determine if this fabrication method aligns with your project requirements, consider your specific performance targets:

- If your primary focus is Maximum Efficiency: Prioritize this equipment for its ability to achieve perfect impedance matching through nanometer-scale thickness control.

- If your primary focus is Device Reliability: Leverage the high purity and excellent uniformity of PVD systems to ensure consistent performance across the entire solar absorber surface.

Precision in fabrication is the single most important factor in translating theoretical solar design into high-performance reality.

Summary Table:

| Key Advantage | Technical Benefit | Impact on Solar Performance |

|---|---|---|

| Nanometer Control | Precise layer thickness | Enables fine optical interference effects |

| Impedance Matching | Minimized reflection | Maximizes light absorption efficiency |

| High Purity | Contaminant-free deposition | Enhances film optical properties and life |

| Film Uniformity | Consistent surface area | Prevents performance weak points and hot spots |

Elevate Your Solar Research with KINTEK Precision

Don't let fabrication inconsistencies hinder your efficiency goals. KINTEK provides industry-leading Tube, Vacuum, CVD, and Muffle furnace systems specifically designed for the rigorous demands of PVD and thin-film deposition. Backed by expert R&D and specialized manufacturing, our systems offer the nanometer-scale control and high purity required to achieve perfect impedance matching for your solar absorbers. Whether you need a standard setup or a fully customizable solution tailored to your unique research needs, our team is ready to support your innovation.

Ready to achieve superior film uniformity? Contact KINTEK today to discuss your project requirements!

Visual Guide

References

- Cheng‐Fu Yang, Kuei‐Kuei Lai. Development and Fabrication of a Multi-Layer Planar Solar Light Absorber Achieving High Absorptivity and Ultra-Wideband Response from Visible Light to Infrared. DOI: 10.3390/nano14110930

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What role does a high-temperature sintering furnace play in lead-free piezoelectric ceramics? Optimizing Performance

- What is the purpose of treating EAF dust in a dryer? Ensure Precise Material Characterization & Data Integrity

- What is the primary function of drying bovine horn biomass for PVC biocomposites? Optimize Material Strength

- How does diamond benefit 5G technology? Unlock Peak Performance with Superior Thermal Management

- What are the advantages and disadvantages of microwave drying for iron ore briquettes? Expert Process Insights

- Why is a constant temperature drying oven set to 60°C for 24 hours? Optimizing Sr4Al6O12SO4 Powder Quality

- How is a laboratory oven utilized during the impregnation stage of APC preparation? Optimize Biochar Activation

- Why is a forced air circulation oven required for Al-Cu-Mn alloy aging? Achieve Peak Hardness with Uniform Heat