Microwave drying technology fundamentally changes how moisture is removed from iron ore briquettes by utilizing electromagnetic waves rather than external heat sources. This method offers exceptional processing speed and energy efficiency, but it introduces distinct risks regarding the physical integrity of the final product.

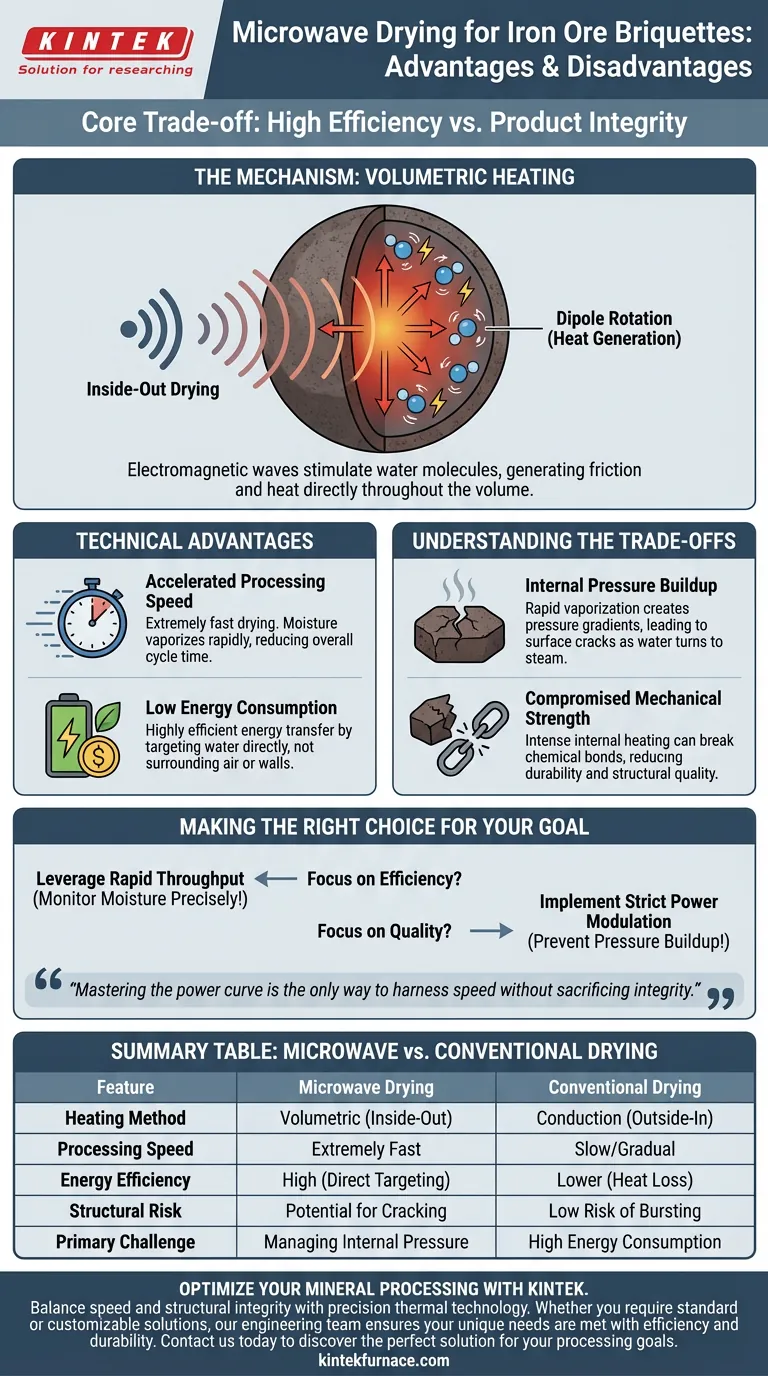

The Core Trade-off Microwave drying utilizes volumetric heating to dry briquettes from the inside out, offering a highly efficient low-energy solution. However, this internal heating mechanism creates pressure gradients that can lead to surface cracking and reduced mechanical strength if power levels are not rigorously controlled.

The Mechanism: Volumetric Heating

Inside-Out Drying

Unlike conventional drying, which relies on heat conduction from the surface to the core, microwave drying achieves volumetric heating.

This means the heat is generated simultaneously throughout the entire volume of the briquette.

Dipole Rotation

The process works by stimulating water molecules within the iron ore matrix.

The electromagnetic waves cause dipole rotation of these molecules, generating friction and heat directly where the moisture resides.

Technical Advantages

Accelerated Processing Speed

The primary advantage of this technology is the extremely fast drying speed.

Because heat does not need to slowly penetrate from the outside, moisture is vaporized rapidly, significantly reducing the overall cycle time for processing.

Energy Consumption

Microwave drying is noted for low energy consumption relative to traditional thermal methods.

By targeting the water molecules directly rather than heating the surrounding air or equipment walls, energy transfer is far more efficient.

Understanding the Trade-offs

Internal Pressure Buildup

The rapid vaporization of water inside the briquette creates a unique challenge: internal pressure.

As water turns to steam within the core, pressure builds up faster than it can escape, which can lead to surface cracks as the material expands.

Compromised Mechanical Strength

There is a direct correlation between power intensity and the structural quality of the iron ore.

If the power is not properly controlled, the intense internal heating can cause the breakage of chemical bonds between grains.

This degradation significantly reduces the mechanical strength of the briquette, making it less durable for transport or subsequent processing.

Making the Right Choice for Your Goal

To successfully implement microwave drying, you must balance the need for throughput with the requirement for material durability.

- If your primary focus is process efficiency: Leverage microwave drying to achieve rapid throughput and reduced energy costs, but ensure your moisture monitoring systems are precise.

- If your primary focus is product quality: Implement strict power modulation protocols to prevent rapid pressure buildup, preserving the chemical bonds and mechanical strength of the briquette.

Mastering the power curve is the only way to harness the speed of microwave drying without sacrificing the integrity of the iron ore.

Summary Table:

| Feature | Microwave Drying | Conventional Drying |

|---|---|---|

| Heating Method | Volumetric (Inside-Out) | Conduction (Outside-In) |

| Processing Speed | Extremely Fast | Slow/Gradual |

| Energy Efficiency | High (Direct Targeting) | Lower (Heat Loss) |

| Structural Risk | Potential for Cracking | Low Risk of Bursting |

| Primary Challenge | Managing Internal Pressure | High Energy Consumption |

Optimize Your Mineral Processing with KINTEK

Balance speed and structural integrity with precision thermal technology. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of material science. Whether you require standard lab high-temp furnaces or fully customizable solutions for iron ore processing and beyond, our engineering team ensures your unique needs are met with efficiency and durability.

Ready to enhance your lab’s efficiency? Contact us today to discover the perfect solution for your processing goals.

Visual Guide

References

- Rishi Sharma, D. S. Nimaje. Study of drying kinetics and moisture diffusivity in iron ore briquettes after using different drying techniques. DOI: 10.2298/jmmb240910010s

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- What is the purpose of sintering in materials science? Transform Powders into Dense, High-Strength Components

- What is the function of a laboratory oven in activated carbon preparation? Ensure Superior Material Stability

- Why is a high-temperature furnace with gas flow control necessary for Li6MnO4 precursors? Achieve Precise Synthesis

- What is the purpose of using a precision oven for HAp-Fe3O4 drying? Achieve 110°C Stability & High Porosity

- How do industrial molds and 10 MPa pressure impact PEEK quality? Unlock Superior Density & Structural Integrity

- What critical environmental conditions does a high-temperature recrystallization annealing furnace provide? Maximize Steel Strength

- What is the function of a magnetron sputtering system for WS2 thin films? Master Nano-Scale Deposition Control

- What core processing conditions does a laboratory high-temperature oven provide? Optimize Geopolymer Curing Results