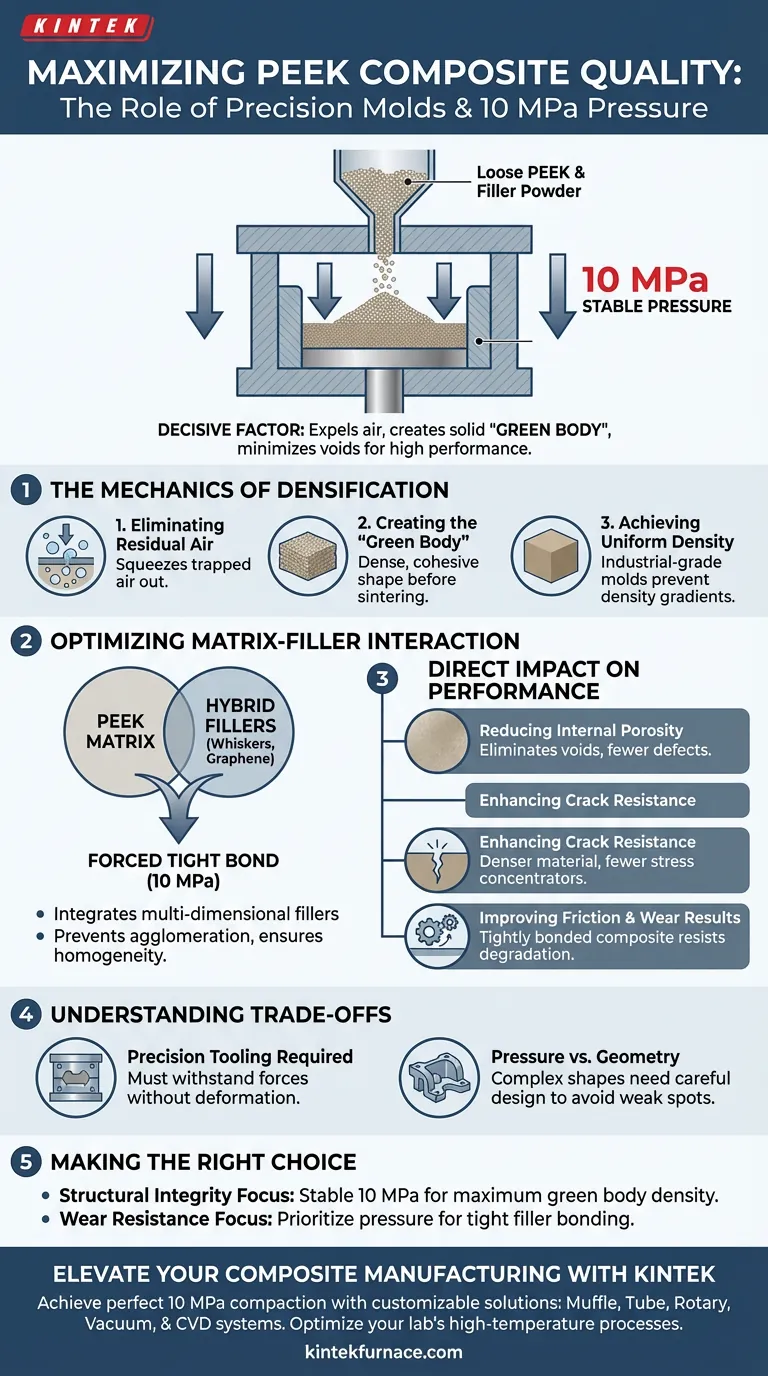

Using industrial-grade precision molds to apply a stable 10 MPa pressure is the decisive factor in maximizing the density and structural integrity of PEEK composites. This specific pressure setting compacts loose mixed powder into a solid "green body" by forcibly expelling residual air trapped between particles. By minimizing internal voids at this stage, you establish the physical foundation required for high-performance applications.

The application of 10 MPa pressure is not merely about shaping the part; it is a critical quality control measure. It forces the PEEK matrix to bond tightly with complex fillers, directly determining the composite's final resistance to cracking and wear.

The Mechanics of Densification

Eliminating Residual Air

Loose powder mixtures naturally contain significant amounts of trapped air. Applying 10 MPa of pressure is the threshold required to effectively squeeze this air out of the mixture.

Creating the "Green Body"

This process transforms the loose powder into a dense, cohesive shape known as a green body. This compacted state is essential for maintaining geometric stability before the material undergoes final heating or sintering.

Achieving Uniform Density

Using industrial-grade precision molds ensures that this pressure is applied evenly across the entire part. This prevents density gradients, where some areas might be porous and weak while others are dense.

Optimizing Matrix-Filler Interaction

Integrating Multi-Dimensional Fillers

High-performance PEEK composites often rely on hybrid fillers, such as Potassium Titanate Whiskers and Graphene Nanoplatelets. These materials have complex shapes that are difficult to encapsulate.

Forcing a Tight Bond

The 10 MPa load forces the PEEK polymer matrix to flow around and tightly grip these microscopic reinforcements. Without this pressure, gaps would remain between the filler and the plastic, creating weak points.

Ensuring Homogeneity

Proper compaction prevents the fillers from agglomerating (clumping together). It ensures they are locked into the matrix in a uniform distribution, which is vital for consistent material properties.

The Direct Impact on Performance

Reducing Internal Porosity

Porosity is the enemy of structural integrity. By eliminating voids during the molding phase, you significantly reduce the likelihood of internal defects in the final product.

Enhancing Crack Resistance

A denser material with lower porosity has fewer internal stress concentrators. This directly translates to improved crack resistance under mechanical load.

Improving Friction and Wear Results

The structural integrity gained from this process is most evident during friction and wear testing. A tightly bonded, non-porous composite resists surface degradation much better than a loosely compacted one.

Understanding the Trade-offs

The Requirement for Precision Tooling

You cannot apply 10 MPa of pressure effectively with low-quality tooling. Industrial-grade molds are required to withstand these forces without deforming or allowing material to "flash" (leak) out of the seams.

Pressure Uniformity vs. Geometry

While 10 MPa is ideal for compaction, complex part geometries can make it difficult to distribute this pressure evenly. Poor mold design can lead to "pressure shadows," resulting in localized weak spots despite the correct machine settings.

Making the Right Choice for Your Goal

To maximize the quality of your PEEK composites, consider your specific performance requirements:

- If your primary focus is Structural Integrity: Ensure your tooling can maintain a stable 10 MPa to eliminate porosity and maximize the density of the green body.

- If your primary focus is Wear Resistance: Prioritize the pressure application to ensure the PEEK matrix tightly bonds with reinforcements like Graphene Nanoplatelets.

Ultimately, precision molding at 10 MPa bridges the gap between a mixture of raw ingredients and a unified, high-performance composite material.

Summary Table:

| Parameter | Influence on PEEK Quality | Key Benefit |

|---|---|---|

| Pressure Setting | Constant 10 MPa load | Expels residual air to eliminate internal voids |

| Mold Quality | Industrial-grade precision | Ensures uniform density and prevents part deformation |

| Green Body Formation | High-pressure compaction | Maintains geometric stability for final sintering |

| Filler Integration | Forced matrix-filler bonding | Enhances crack resistance and wear performance |

Elevate Your Composite Manufacturing with KINTEK

Achieving the perfect 10 MPa compaction requires precision and reliability. Backed by expert R&D and manufacturing, KINTEK offers high-performance laboratory solutions—including customizable Muffle, Tube, Rotary, Vacuum, and CVD systems—designed to meet your unique material processing needs. Whether you are developing high-density PEEK composites or advanced ceramics, our equipment ensures the thermal and structural consistency your research demands.

Ready to optimize your lab's high-temperature processes? Contact KINTEK today to discuss your project requirements!

Visual Guide

References

- Zhengjia Ji, Chao Xu. Potassium Titanate Whisker/Graphene Multi-Dimensional Fillers to Improve the Wear Resistance of Poly(Ether Ether Ketone) Composite. DOI: 10.3390/lubricants13050211

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Spark Plasma Sintering SPS Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary purpose of high-temperature pyrolysis? Unlock Superior PFAS Removal with Enhanced Hydrophobicity

- How are heat treatment furnaces utilized in the automotive industry? Enhance Component Durability and Performance

- What are the advantages of using an acid oxidation bath? Accelerate Lignin Fiber Stabilization from Hours to Minutes

- How does a swirling flow field influence the residence time of pure ammonia fuel within a furnace? Maximize Efficiency

- Why is a constant temperature incubator required for 10-week fungal testing of Moso Bamboo? Ensure Testing Accuracy

- What is the primary function of multi-stage oxidation ovens? Secure High-Strength Carbon Fiber Stabilization

- Why is high-temperature homogenization necessary for refractory alloy thermal expansion tests? Ensure Data Precision.

- Why is constant temperature heating required for HfC precursors? Master HfOC/SiOC Composite Pre-treatment