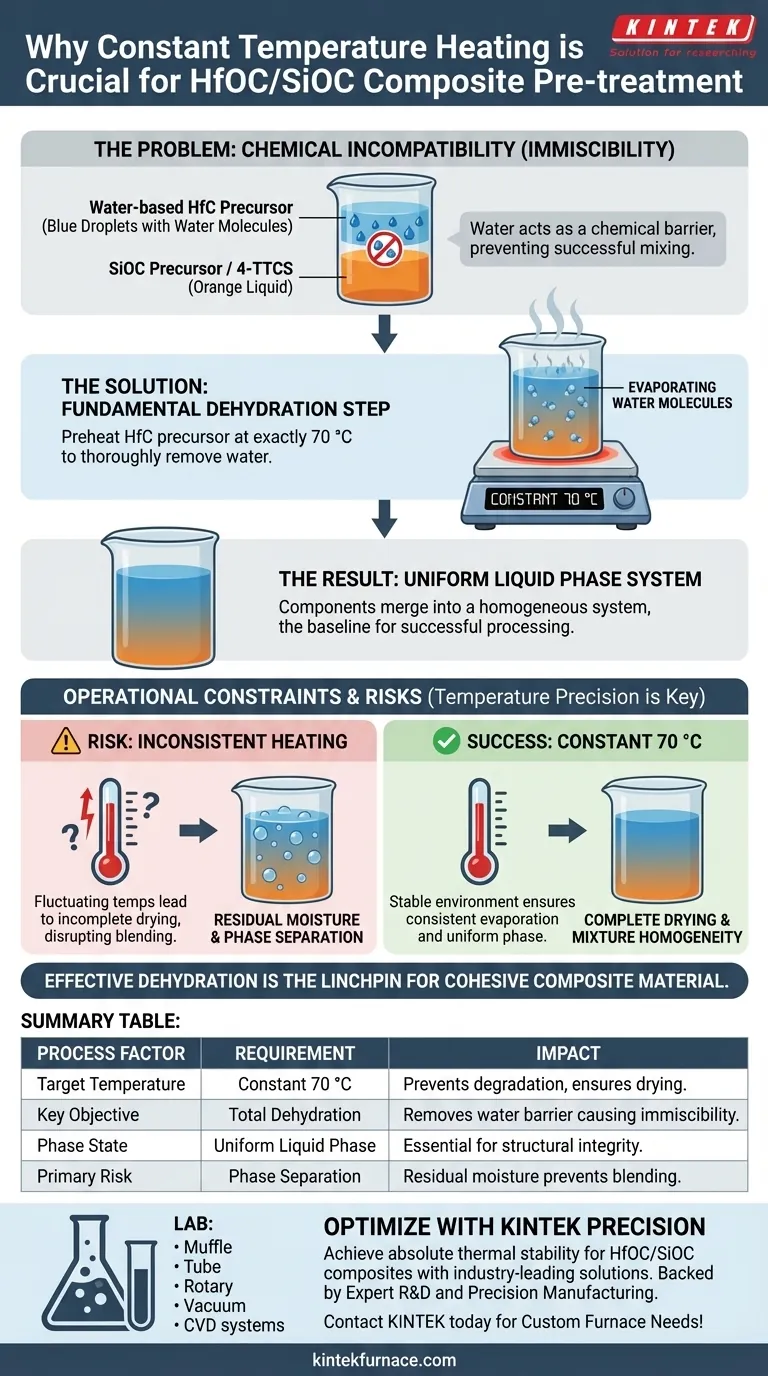

Constant temperature heating is the fundamental dehydration step required to ensure chemical compatibility. It is utilized to preheat water-based HfC precursors at exactly 70 °C to thoroughly remove water molecules. Without this specific drying process, the water acts as a chemical barrier, preventing the HfC precursor from mixing successfully with the SiOC precursor.

The removal of water is not a suggestion but a chemical necessity. Water causes immiscibility between the precursor components, meaning they physically cannot blend into the uniform liquid phase required for high-quality composite formation.

The Critical Role of Dehydration

Solving the Immiscibility Problem

Liquid HfC precursors differ significantly in composition from liquid SiOC precursors, such as 4-TTCS.

The HfC precursors are water-based, which creates an inherent compatibility issue.

As long as water is present, these two distinct liquids remain immiscible, effectively repelling each other rather than integrating.

Creating a Uniform Liquid Phase

To synthesize a successful HfOC/SiOC composite, the starting materials must blend into a single, homogeneous system.

Heating the HfC precursor eliminates the interfering water molecules, thereby removing the primary barrier to mixing.

This allows the components to merge into a uniform liquid phase system, which is the absolute baseline requirement for successful processing.

Operational Constraints and Risks

The Necessity of Temperature Precision

The process specifically requires maintaining the precursor at 70 °C.

Constant temperature equipment is necessary to ensure the drying environment is stable and the evaporation of water is consistent.

Fluctuating temperatures could lead to incomplete drying or thermal degradation of the precursor itself.

The Risk of Residual Moisture

If the heating is inconsistent, water molecules may remain trapped within the HfC precursor.

Even trace amounts of residual water will disrupt the blending process with the SiOC precursor.

This failure to dry the material completely will result in phase separation, compromising the structural integrity of the final composite.

Ensuring Process Success

- If your primary focus is Mixture Homogeneity: Prioritize the complete removal of water at 70 °C to ensure the HfC and 4-TTCS precursors can form a single, unified phase.

- If your primary focus is Process Control: specific constant temperature equipment must be used to prevent thermal fluctuations that lead to incomplete dehydration.

Effective dehydration is the linchpin that transforms incompatible liquids into a cohesive composite material.

Summary Table:

| Process Factor | Requirement | Impact on HfOC/SiOC Quality |

|---|---|---|

| Target Temperature | Constant 70 °C | Prevents thermal degradation and ensures complete drying. |

| Key Objective | Total Dehydration | Removes the water barrier causing immiscibility with SiOC. |

| Phase State | Uniform Liquid Phase | Essential for the structural integrity of the final composite. |

| Primary Risk | Phase Separation | Residual moisture prevents blending with 4-TTCS precursors. |

Optimize Your Composite Synthesis with KINTEK Precision

Achieving a uniform liquid phase for HfOC/SiOC composites requires the absolute thermal stability that only professional-grade equipment can provide. KINTEK empowers your research with industry-leading laboratory solutions tailored for advanced material pre-treatment.

Backed by expert R&D and precision manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific 70 °C dehydration protocols and high-temp requirements. Don't let phase separation compromise your results—ensure chemical compatibility with our reliable heating technology.

Ready to elevate your lab's efficiency? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Arijit Roy, Gurpreet Singh. Preparation and characterization of HfOC/SiOC composite powders and fibermats <i>via</i> the polymer pyrolysis route. DOI: 10.1039/d5ra02006a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- Why is a furnace with programmed temperature control required for catalyst regeneration? Ensure Catalyst Stability

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- Why is a vacuum drying oven necessary for activated carbon? Ensure Accurate BET and Pore Size Analysis

- What inert gas is commonly used in gloveboxes and Schlenk lines, and why is it preferred over nitrogen in some cases? Discover Argon's Superior Inertness for Sensitive Experiments

- Why is determining the hypercooling limit necessary when measuring the heat of fusion? Optimize Your Material Research

- Why is industrial-grade isostatic pressing necessary for zirconia? Achieve Uniform Density & Structural Integrity

- How does a symmetric suction design improve steel wire heat treatment? Achieve Uniform Salt Flow and Sorbite Quality

- What is the purpose of the constant-temperature circulation phase? Ensure Moso Bamboo Integrity with KINTEK Solutions