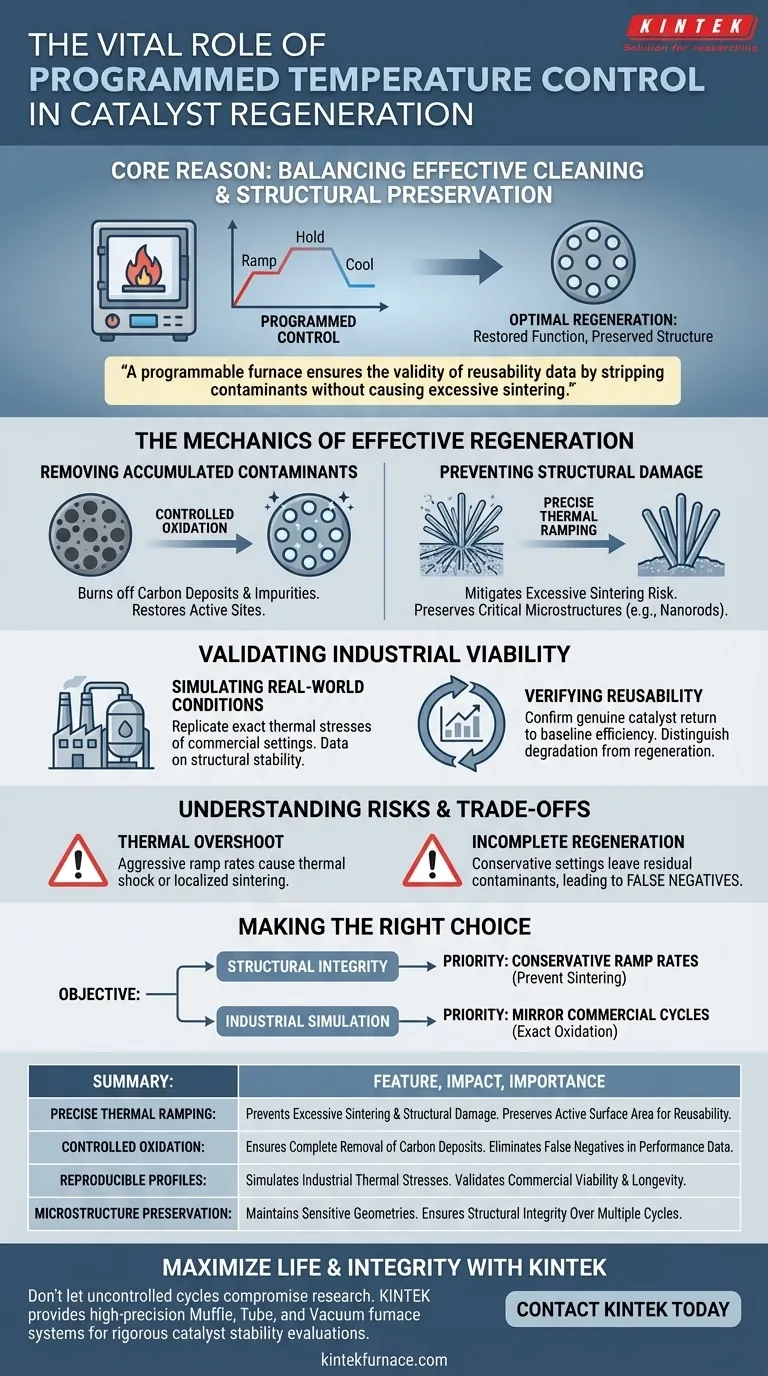

Programmed temperature control is the only reliable method to balance effective cleaning with structural preservation. During catalyst stability evaluations, this equipment enables the precise removal of accumulated carbon deposits and chemically adsorbed impurities through controlled oxidation. Without this specific control, researchers risk either incomplete regeneration or irreversible damage to the catalyst's active components.

A programmable furnace ensures the validity of reusability data by stripping contaminants without causing excessive sintering. It transforms a basic cleaning step into a rigorous verification of industrial viability.

The Mechanics of Effective Regeneration

Removing Accumulated Contaminants

During repeated reaction cycles, catalysts naturally accumulate unwanted byproducts. These typically take the form of carbon deposits or chemically adsorbed impurities that block active sites.

To restore the catalyst's function, these impurities must be burned off. A programmable furnace facilitates this through controlled oxidation, ensuring the environment is aggressive enough to clean the material but controlled enough to preserve it.

Preventing Structural Damage

The greatest risk during regeneration is thermal damage. Uncontrolled heating can lead to excessive sintering, where the active components of the catalyst fuse together and lose surface area.

Programmed temperature control mitigates this risk by ramping heat precisely. This preserves critical microstructures, such as nanorod-shaped cerium oxide, ensuring the material retains the geometry required for high performance.

Validating Industrial Viability

Simulating Real-World Conditions

Industrial applications demand catalysts that can withstand multiple lifecycles, not just a single run. Stability evaluations must simulate these harsh conditions accurately.

By using programmed control, you replicate the exact thermal stresses a catalyst would face in a commercial setting. This provides necessary data on the material's structural stability over time.

Verifying Reusability

The goal of stability testing is to prove that a catalyst can return to a baseline state of efficiency.

Precise temperature regulation confirms that the catalyst is genuinely reusable. It distinguishes between a material that has simply degraded and one that has been successfully regenerated for another cycle.

Understanding the Risks and Trade-offs

The Danger of Thermal Overshoot

While a programmable furnace offers precision, it relies entirely on the correctness of the thermal profile. An aggressively programmed ramp rate can still cause thermal shock or localized sintering, regardless of the equipment's capability.

Incomplete Regeneration

Conversely, being too conservative with temperature settings to protect the structure may result in residual contaminants. This leads to false negatives in stability data, where a catalyst appears to degrade simply because it was never fully cleaned.

Making the Right Choice for Your Goal

To ensure your stability evaluations yield actionable data, tailor your approach based on your specific objectives:

- If your primary focus is Structural Integrity: Prioritize conservative ramp rates to prevent sintering, especially when working with sensitive nanostructures like cerium oxide nanorods.

- If your primary focus is Industrial Simulation: Configure the furnace to mirror the exact oxidation cycles and temperatures used in large-scale commercial reactors.

Precision in regeneration is the defining factor that separates a theoretical experiment from a commercially viable solution.

Summary Table:

| Feature | Impact on Catalyst Regeneration | Importance in Stability Evaluation |

|---|---|---|

| Precise Thermal Ramping | Prevents excessive sintering and structural damage | Preserves active surface area for reusability |

| Controlled Oxidation | Ensures complete removal of carbon deposits | Eliminates false negatives in performance data |

| Reproducible Profiles | Simulates industrial thermal stresses | Validates commercial viability and longevity |

| Microstructure Preservation | Maintains sensitive geometries (e.g., nanorods) | Ensures structural integrity over multiple cycles |

Maximize the Life and Integrity of Your Catalysts with KINTEK

Don't let uncontrolled thermal cycles compromise your research. KINTEK provides high-precision Muffle, Tube, and Vacuum furnace systems specifically designed for rigorous catalyst stability evaluations. Backed by expert R&D and world-class manufacturing, our systems offer the customizable programmed temperature control necessary to prevent sintering and ensure industrial-grade regeneration.

Ready to elevate your lab's thermal processing? Contact KINTEK today to discover how our customizable high-temperature solutions can deliver the precise results your research demands.

Visual Guide

References

- Mara Arduino, Fabio Alessandro Deorsola. Understanding the Role of Morphology in the Direct Synthesis of Diethyl Carbonate Over Ceria‐Based Catalysts: An In Situ Infrared and High‐Resolution TEM Study. DOI: 10.1002/cctc.202500140

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the necessity of carbon coating for silicon anodes? Engineering Durability for High-Performance Batteries

- What is the necessity of in-situ DRIFTS in formaldehyde oxidation? Uncover Real-Time Catalytic Reaction Mechanisms

- What are the advantages of using a batch furnace? Achieve Unmatched Process Flexibility and Precision

- What is the function of the nitrogen source in biomass pyrolysis? Optimize Bio-Oil Yield and Ensure Process Safety

- Why is a high vacuum necessary for solar absorbers? Ensure Precise Optical Properties in Thin Film Coating

- How does the secondary heat treatment process improve battery performance? Optimize SHPC/N-CNT Composites Today

- What is the purpose of heating the nickel nitrate and biomass mixture to 150°C? Achieve Superior Catalyst Dispersion

- What advantages does peat char offer compared to traditional charcoal? Boost Your Furnace Efficiency by 22%