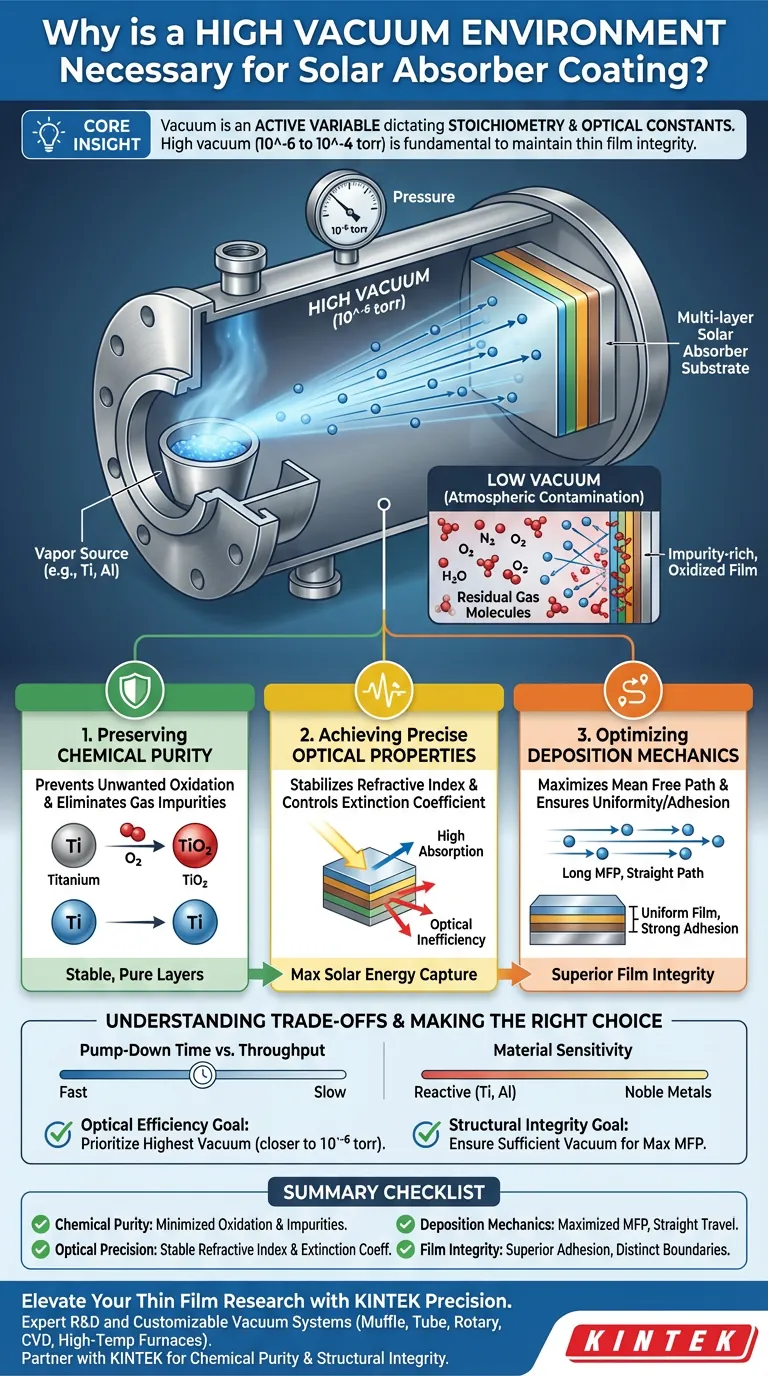

A high vacuum environment is fundamentally required to maintain the chemical and physical integrity of the thin films used in solar absorbers. Specifically, laboratory-grade systems must operate between 10^-6 and 10^-4 torr to minimize residual gas molecules, preventing them from reacting with the coating materials or physically scattering the vapor stream during deposition.

Core Insight: The vacuum is not just about keeping the chamber clean; it is an active variable that dictates the stoichiometry and optical constants of the final coating. Without high vacuum, unintended oxidation alters the refractive index of layers like alumina and titanium, rendering the multi-layer design optically inefficient.

Preserving Chemical Purity

To function correctly, a multi-layer solar absorber requires precise chemical composition. The vacuum environment is the primary defense against atmospheric contamination.

Preventing Unwanted Oxidation

Materials often used in solar absorbers, such as titanium, are highly reactive.

If residual oxygen is present in the chamber, these materials will oxidize before or during their deposition onto the substrate. This uncontrolled oxidation changes the material from a pure metal or specific dielectric into an oxide with completely different properties.

Eliminating Gas Impurities

Residual gas molecules do not just float in the chamber; they can become embedded within the growing film.

Operating at high vacuum minimizes the inclusion of these impurities. This ensures that the functional layers remain chemically pure, which is critical for the stability and longevity of the solar absorber.

Achieving Precise Optical Properties

The efficiency of a planar solar absorber is determined by how it interacts with light. This interaction is governed by strict material constants that rely on the purity established by the vacuum.

Stabilizing the Refractive Index

The refractive index determines how light propagates through the multi-layer stack.

If the chemical composition shifts due to impurities or oxidation, the refractive index changes. This mismatch causes light to reflect or scatter rather than being absorbed, degrading the device's performance.

Controlling the Extinction Coefficient

The extinction coefficient defines how strongly the material absorbs light at a given wavelength.

A high vacuum ensures that the deposited layers maintain the specific extinction coefficients calculated during the design phase. This guarantees that the solar energy is captured effectively rather than being lost.

Optimizing Deposition Mechanics

Beyond chemistry, the vacuum dictates the physical path the vaporized material takes from the source to the substrate.

Maximizing the Mean Free Path

In a high vacuum, the density of gas molecules is low enough to increase the mean free path of the vaporized atoms.

This ensures that the coating material travels in a straight line without colliding with residual gas molecules. This prevents the scattering of atoms, leading to a more efficient and direct deposition process.

Ensuring Uniformity and Adhesion

When atoms arrive at the substrate without scattering, they deposit with higher energy and directional uniformity.

This results in a film with consistent thickness and strong adhesion to the substrate. Uniformity is vital for maintaining the distinct boundaries required between the multiple layers of the absorber.

Understanding the Trade-offs

While high vacuum is essential for quality, achieving and maintaining it presents operational challenges.

Pump-Down Time vs. Throughput

Reaching pressures of 10^-6 torr requires significant time, which limits the number of runs per day.

You must balance the strict need for optical precision against the practical constraints of research timelines. However, for laboratory-grade solar absorbers, sacrificing vacuum quality for speed almost always results in unusable data.

Material Sensitivity

Not all materials are equally sensitive to vacuum levels.

While noble metals might forgive a slightly lower vacuum, reactive materials like titanium or aluminum permit no compromise. You must tailor your vacuum protocols to the most sensitive material in your multi-layer stack.

Making the Right Choice for Your Goal

The specific vacuum level you target should be dictated by the most critical performance metric of your solar absorber.

- If your primary focus is Optical Efficiency: Prioritize the highest possible vacuum (closer to 10^-6 torr) to prevent oxidation and strictly control the refractive index and extinction coefficient.

- If your primary focus is Structural Integrity: Ensure the vacuum is sufficient to maximize the mean free path, guaranteeing uniform thickness and strong adhesion between layers.

Success in vacuum evaporation depends on treating the vacuum level as a critical material component, just as important as the source metals themselves.

Summary Table:

| Key Factor | Impact of High Vacuum | Scientific Benefit |

|---|---|---|

| Chemical Purity | Minimizes residual oxygen and gas impurities | Prevents unintended oxidation of reactive materials like Ti or Al |

| Optical Precision | Stabilizes refractive index and extinction coefficient | Ensures high solar energy capture and minimal light scattering |

| Deposition Mechanics | Maximizes Mean Free Path (MFP) | Promotes straight-line vapor travel and uniform film thickness |

| Film Integrity | Enhances atom arrival energy | Results in superior adhesion and distinct layer boundaries |

Elevate Your Thin Film Research with KINTEK Precision

Precise control over vacuum levels is the difference between a high-efficiency solar absorber and a failed experiment. KINTEK provides the advanced technology required to master these variables. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized lab high-temp furnaces—all fully customizable to meet your unique deposition requirements.

Don't let atmospheric impurities compromise your optical constants. Partner with KINTEK to achieve the chemical purity and structural integrity your research demands.

Contact our technical experts today to discuss your custom furnace needs

Visual Guide

References

- Cheng‐Fu Yang, Kuei‐Kuei Lai. Development and Fabrication of a Multi-Layer Planar Solar Light Absorber Achieving High Absorptivity and Ultra-Wideband Response from Visible Light to Infrared. DOI: 10.3390/nano14110930

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why is precise nitrogen flow critical for AlN nanofibers? Mastering High-Performance Nitridation Results

- How is mechanochemical grinding used in lithium battery recovery? Unlock Efficient Solid-State Material Repair

- How do continuous furnaces differ from batch furnaces? Choose the Right Furnace for Your Production Needs

- Why are high-precision constant temperature baths necessary? Unlock Accurate Fiber Optic Sensor Calibration

- What is the role of industrial thermometers in monitoring thermal stress? Ensure Safety via High-Precision Data

- Why is film uniformity important in semiconductor manufacturing? Ensure High Device Performance and Yield

- What is the function of aluminum foil in leather combustion experiments? Optimize Thermal Isolation and Accuracy

- What is the purpose of the annealing process in OLED preparation? Optimize Film Stability and Device Efficiency