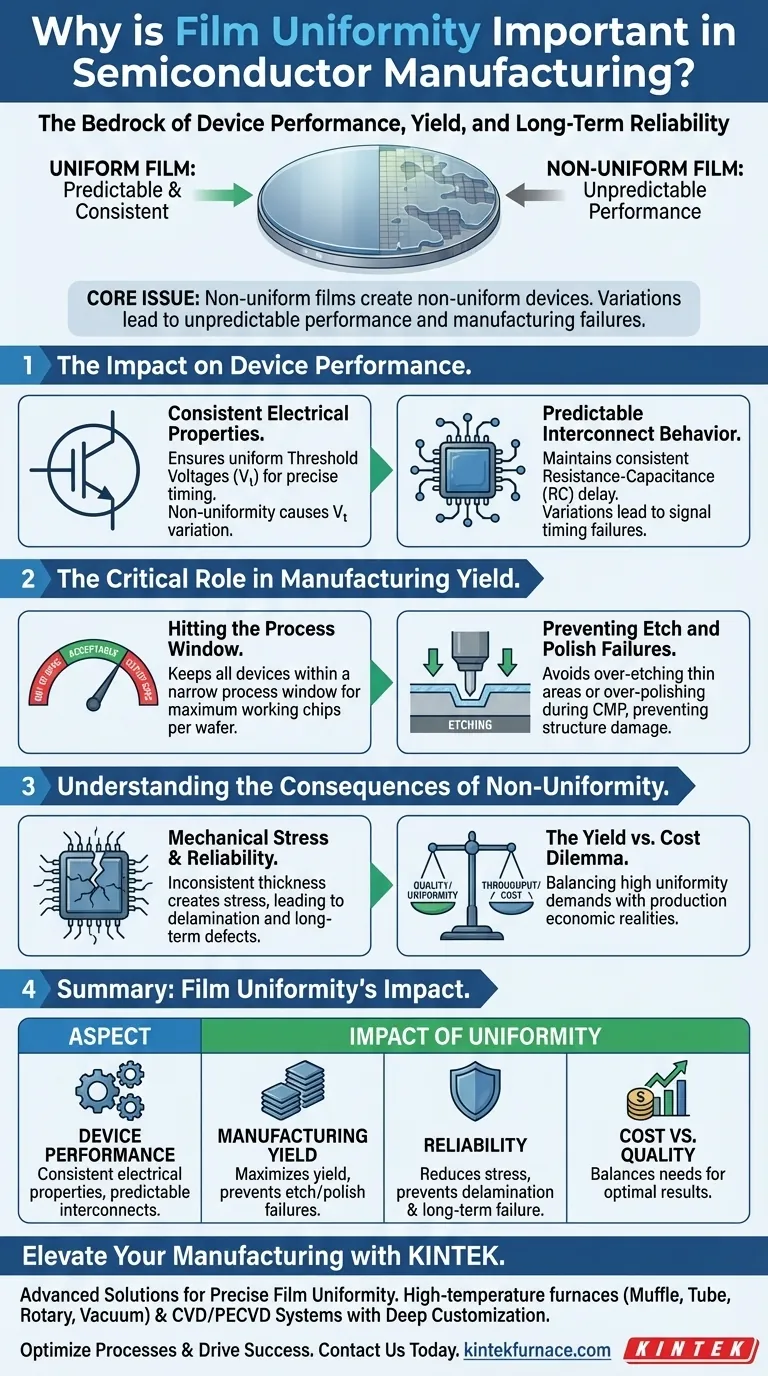

In semiconductor manufacturing, film uniformity is the bedrock of device performance, manufacturing yield, and long-term reliability. It is the critical factor that ensures every one of the billions of transistors on a silicon wafer behaves predictably and consistently. Without it, mass-producing functional integrated circuits would be impossible.

The core issue is simple: non-uniform films create non-uniform devices. When film thickness varies across a wafer, the electrical and physical properties of the transistors and interconnects also vary, leading to unpredictable performance and widespread manufacturing failures.

The Impact on Device Performance

At the nanometer scales of modern chips, even slight variations in film thickness have a dramatic effect on how the final device functions.

Consistent Electrical Properties

The thickness of a deposited film directly governs fundamental electrical characteristics. For example, the gate oxide layer in a transistor controls its switching behavior.

A non-uniform gate oxide means transistors in different locations will have different threshold voltages (Vt), causing them to turn on at different times. This variability destroys the precise timing required for a complex circuit to operate.

Predictable Interconnect Behavior

Similarly, the thickness of metal and dielectric layers determines the Resistance-Capacitance (RC) delay of the wires connecting transistors.

Variations in these films lead to inconsistent signal travel times across the chip. Some paths become too slow, causing timing failures that render the entire chip useless.

The Critical Role in Manufacturing Yield

Uniformity is not just about performance; it is a prerequisite for successfully manufacturing a device in the first place. Every step in the fabrication process is calibrated with the assumption of a uniform starting surface.

Hitting the Process Window

Semiconductor fabrication operates within an extremely narrow process window, which defines the acceptable range of parameters for a given step.

Excellent film uniformity ensures that all devices across the entire wafer fall within this critical window. Non-uniformity pushes devices "out of spec," directly causing a reduction in yield—the percentage of working chips per wafer.

Preventing Etch and Polish Failures

Subsequent manufacturing steps, like etching and Chemical-Mechanical Planarization (CMP), are highly dependent on film thickness.

If a film is not uniform, an etch process might completely remove the film in thinner areas before it has finished patterning the thicker areas. Likewise, CMP can over-polish thin regions, damaging underlying structures.

Understanding the Consequences of Non-Uniformity

Striving for uniformity is a constant battle against physical and chemical limitations. Failing to manage it has severe consequences.

Mechanical Stress and Reliability

When a film's thickness is inconsistent, it creates gradients in mechanical stress across the wafer.

These stress points can cause a number of long-term reliability failures, including film delamination (peeling), cracking, and other physical defects that emerge over the lifetime of the device.

The Yield vs. Cost Dilemma

Achieving near-perfect uniformity is technologically demanding and expensive. Deposition tools capable of higher uniformity often have lower throughput or higher costs.

Engineers must constantly balance the need for tighter uniformity against the economic realities of production. This trade-off between perfect quality and manufacturing cost is a central challenge in the industry.

Evaluating Uniformity for Your Goal

How you approach film uniformity depends on your specific role and objective.

- If your primary focus is device design: You must incorporate expected film variations into your simulation models to ensure your chip is robust enough to function despite minor process imperfections.

- If your primary focus is process integration: Your goal is to select and optimize deposition and etch processes to minimize within-wafer variation and maximize the process window for all manufacturing steps.

- If your primary focus is reliability engineering: You must analyze how film non-uniformity creates stress points and use this data to predict and mitigate long-term failure modes.

Ultimately, controlling film uniformity is synonymous with controlling the performance, yield, and reliability of the final product.

Summary Table:

| Aspect | Impact of Film Uniformity |

|---|---|

| Device Performance | Ensures consistent electrical properties and predictable interconnect behavior |

| Manufacturing Yield | Keeps devices within process windows and prevents etch/polish failures |

| Reliability | Reduces mechanical stress, preventing delamination and long-term failures |

| Cost vs. Quality | Balances uniformity needs with production economics for optimal results |

Elevate your semiconductor manufacturing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise film uniformity to meet your unique experimental requirements, boosting device performance, yield, and reliability. Contact us today to discuss how we can optimize your processes and drive success!

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What future trends are expected in the development of CVD tube furnaces? Discover Smarter, More Versatile Systems

- What are the advantages of CVD tube furnace sintering systems? Achieve Superior Material Control and Purity

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More