At their core, the fundamental difference between continuous and batch furnaces lies in their operational model. A continuous furnace processes materials in an uninterrupted flow, much like an assembly line, while a batch furnace processes a fixed quantity of material in discrete, self-contained cycles. This single distinction in process—flow versus containment—drives every other difference in application, cost, and capability.

The choice between a continuous and batch furnace is a strategic decision about your production philosophy. Continuous furnaces are built for high-volume, standardized manufacturing where efficiency is key, while batch furnaces offer superior flexibility and environmental control for specialized or variable tasks.

Understanding the Core Operational Models

The name of each furnace type clearly describes its method. One operates in a constant, flowing state, while the other operates in distinct, start-and-stop batches.

The Continuous Flow Model

A continuous furnace operates without stopping. Materials are loaded onto a conveyor mechanism and travel at a constant speed through different temperature zones within the furnace.

Each item is heated individually as it moves, ensuring every piece experiences the exact same thermal profile. Many designs integrate heating and cooling sections into one long chamber, allowing parts to exit the system ready for the next process step.

The Discrete Batch Model

A batch furnace functions as a sealed system. A specific quantity of material is loaded into the chamber, the door is sealed, and the entire chamber is brought up to temperature for a set duration.

After the heating cycle is complete, the furnace must cool down before the processed items can be safely removed. This entire load-heat-cool-unload sequence constitutes one "batch."

Key Differentiators in Production

The operational model of each furnace directly impacts its suitability for different production goals, from volume and quality to process flexibility.

Production Volume and Scalability

Continuous furnaces are designed for high-volume production. Their capacity is a function of the conveyor speed and the size of the feed system, which can range from small hoppers to systems handling hundreds of liters per hour.

Batch furnaces are suited for lower or more variable volumes. Their capacity is limited by the physical size of the sealed chamber. Scaling production requires either larger furnaces or, more commonly, multiple batch furnaces operating in parallel.

Process Uniformity and Quality

For part-to-part consistency, continuous furnaces often have an inherent advantage. Because each part travels the same path, it receives an identical heat treatment. This eliminates the "perimeter parts" issue, where items on the outside of a batch heat differently than those in the center.

Batch furnaces can achieve excellent temperature uniformity, but it requires careful engineering and precise loading to ensure heat penetrates the entire load evenly.

Flexibility and Process Control

Batch furnaces offer superior flexibility. As a sealed system, it is ideal for processes requiring a strictly controlled inert or pure atmosphere. Furthermore, the heating recipe (time, temperature, ramp rate) can be changed easily for each new load, making it perfect for R&D or high-mix manufacturing.

Continuous furnaces are far less flexible. The entire system is calibrated for a single, consistent process. Changing the temperature profile is a complex undertaking that impacts the entire production line.

Understanding the Financial and Operational Trade-offs

The initial investment for these furnaces is just one part of the total cost of ownership. Operating costs and maintenance requirements create a more complex financial picture.

Initial Investment and Complexity

Continuous furnaces represent a significant capital investment. They are mechanically complex systems that are more expensive to purchase and install compared to their batch counterparts.

Batch furnaces are generally simpler in design and have a lower upfront cost, making them more accessible for smaller operations or new product lines.

Operating Costs

In high-volume scenarios, continuous furnaces can have a lower energy cost per part. They avoid the need for heavy racks or baskets and eliminate the wasteful energy cycle of repeatedly heating and cooling the entire furnace chamber. The system maintains a stable operating temperature, which is highly efficient.

Batch furnaces consume significant energy bringing the heavy chamber and fixtures up to temperature for every single cycle.

Maintenance and Downtime

The complexity of a continuous furnace means it typically requires more frequent and specialized maintenance. Any downtime is critical, as it halts the entire production line.

Batch furnaces are simpler and often more robust. If one furnace in a multi-furnace facility goes down for maintenance, production can continue on the other units, reducing the impact of downtime.

Making the Right Choice for Your Goal

The best furnace is the one that aligns with your specific operational requirements and business goals. Use these points as a guide for your decision.

- If your primary focus is high-volume, standardized production: A continuous furnace is the superior choice for its efficiency at scale and exceptional part-to-part consistency.

- If your primary focus is process flexibility and varied product mixes: A batch furnace provides the control and adaptability needed for custom jobs, R&D, or low-volume manufacturing.

- If your primary focus is absolute atmospheric control or cleanroom standards: The sealed nature of a batch furnace makes it the more reliable and straightforward option for processes requiring inert or highly pure atmospheres.

- If your primary focus is minimizing cost per part at scale: A continuous furnace's energy efficiency and high throughput will typically yield a lower cost per part despite its higher initial investment.

Understanding this fundamental distinction between flow and containment empowers you to select not just a piece of equipment, but the right production philosophy for your work.

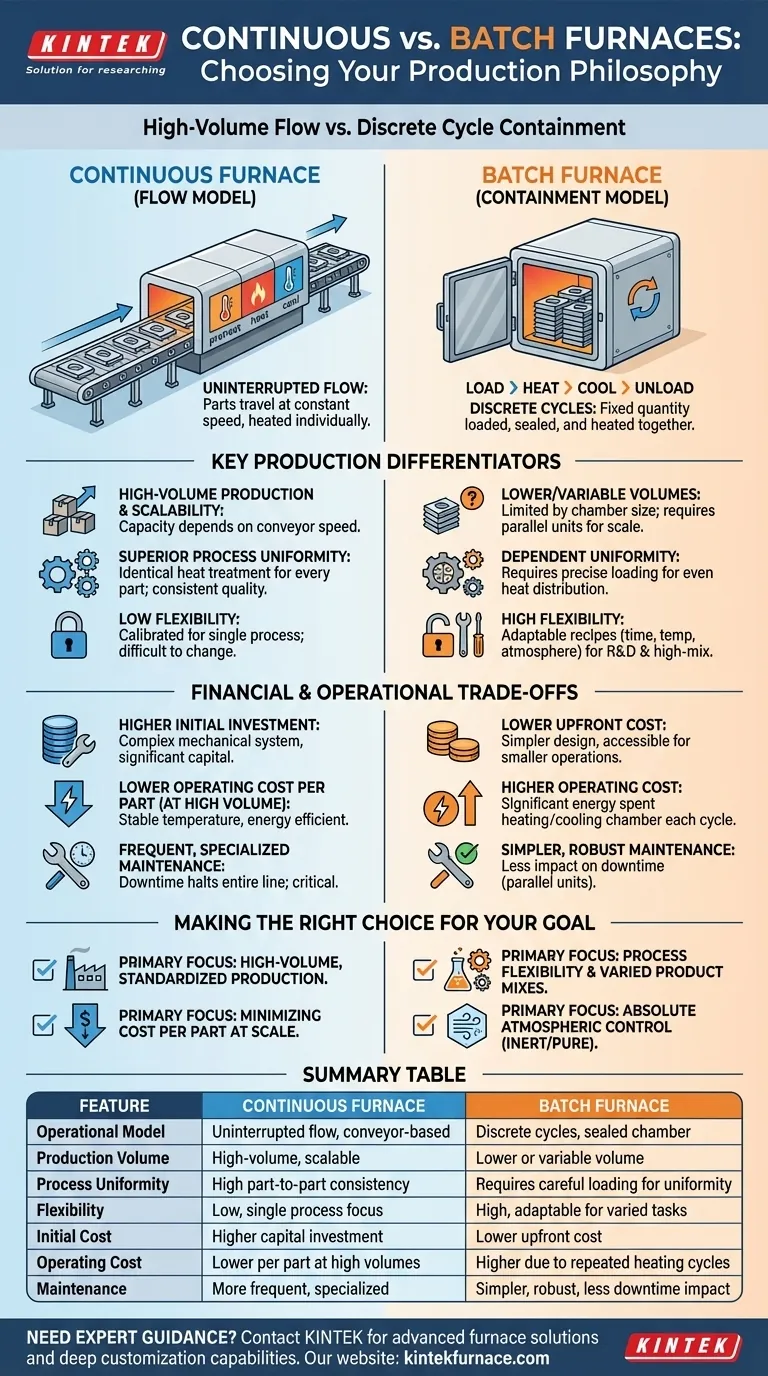

Summary Table:

| Feature | Continuous Furnace | Batch Furnace |

|---|---|---|

| Operational Model | Uninterrupted flow, conveyor-based | Discrete cycles, sealed chamber |

| Production Volume | High-volume, scalable | Lower or variable volume |

| Process Uniformity | High part-to-part consistency | Requires careful loading for uniformity |

| Flexibility | Low, single process focus | High, adaptable for varied tasks |

| Initial Cost | Higher capital investment | Lower upfront cost |

| Operating Cost | Lower per part at high volumes | Higher due to repeated heating cycles |

| Maintenance | More frequent, specialized | Simpler, robust, less downtime impact |

Need expert guidance on selecting the perfect furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're handling high-volume production or specialized tasks, we can help optimize your processes for efficiency and quality. Contact us today to discuss how our solutions can benefit your laboratory!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules