High-precision constant temperature baths are necessary because they generate a strictly controlled reference environment required for accurate data mapping. By immersing fiber optic sensors in stable mediums like ice point baths or molten salt furnaces, engineers can establish a precise correlation between the sensor's optical wavelength shift and the actual physical temperature.

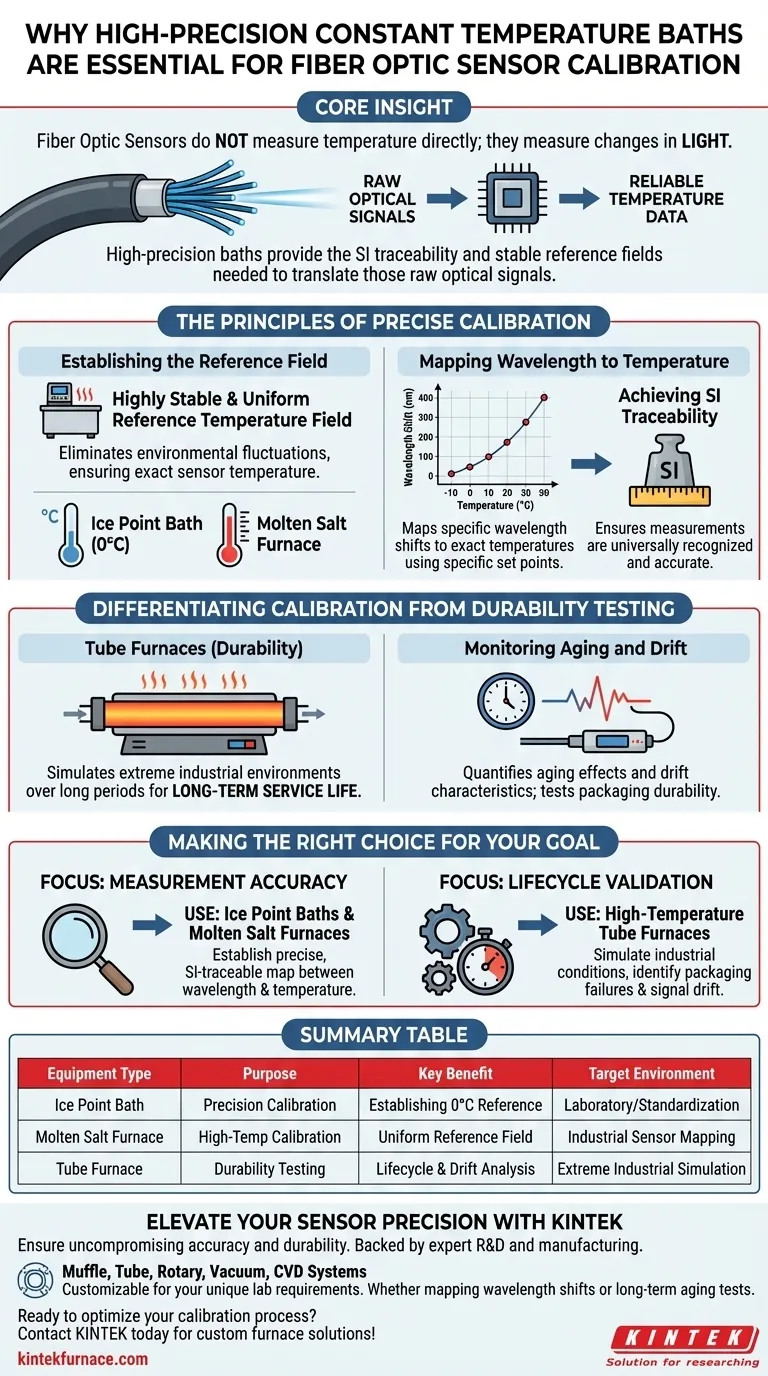

Core Insight: A fiber optic sensor does not measure temperature directly; it measures changes in light. High-precision baths provide the SI traceability and stable reference fields needed to translate those raw optical signals into reliable, standardized temperature data.

The Principles of Precise Calibration

Establishing the Reference Field

To calibrate a fiber optic sensor, you must compare its reading against a known truth.

High-precision constant temperature baths create a highly stable and uniform reference temperature field.

This uniformity eliminates environmental fluctuations, ensuring that the temperature affecting the sensor is exactly what the calibration equipment claims it is.

Mapping Wavelength to Temperature

Fiber optic sensors typically function by detecting a "wavelength shift" in the light passing through them.

However, this shift is meaningless without a reference scale.

Using specific set points—such as an ice point bath (0°C) or an industrial-grade molten salt furnace—allows researchers to map specific wavelength shifts to exact temperatures.

Achieving SI Traceability

Reliability in engineering depends on standardization.

Calibration baths allow researchers to achieve International System of Units (SI) traceability.

This ensures that the measurements taken by your sensor are not just internally consistent, but universally recognized and accurate.

Differentiating Calibration from Durability Testing

The Role of Tube Furnaces

While constant temperature baths focus on immediate calibration accuracy, other tools are required for stress testing.

High-temperature tube furnaces are used to simulate extreme industrial environments over long periods.

Unlike the precise mapping done in a bath, the tube furnace is primarily used to evaluate the long-term service life of the sensor.

Monitoring Aging and Drift

Calibration tells you if a sensor is accurate now; durability testing tells you if it will stay accurate later.

Long-term heating in a tube furnace allows researchers to quantify aging effects and drift characteristics.

This is essential for testing the durability of packaging materials, particularly for sensors destined for the energy sector.

Making the Right Choice for Your Goal

To ensure your fiber optic sensors are ready for deployment, you must match your testing equipment to your specific validation phase.

- If your primary focus is Measurement Accuracy: Prioritize ice point baths and molten salt furnaces to establish a precise, SI-traceable map between wavelength shifts and temperature.

- If your primary focus is Lifecycle Validation: Utilize high-temperature tube furnaces to simulate industrial conditions and identify potential packaging failures or signal drift over time.

Ultimately, high-precision calibration provides the foundational trust that turns a theoretical sensor into a reliable industrial instrument.

Summary Table:

| Equipment Type | Purpose | Key Benefit | Target Environment |

|---|---|---|---|

| Ice Point Bath | Precision Calibration | Establishing 0°C Reference | Laboratory/Standardization |

| Molten Salt Furnace | High-Temp Calibration | Uniform Reference Field | Industrial Sensor Mapping |

| Tube Furnace | Durability Testing | Lifecycle & Drift Analysis | Extreme Industrial Simulation |

Elevate Your Sensor Precision with KINTEK

Ensure your fiber optic sensors deliver uncompromising accuracy and durability. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temp furnaces—all customizable for your unique lab requirements. Whether you are mapping wavelength shifts or conducting long-term aging tests, our equipment provides the stability and uniformity your research demands.

Ready to optimize your calibration process? Contact KINTEK today to discuss our custom furnace solutions!

Visual Guide

References

- Stephan Krenek, K. Anhalt. Fibre-optic thermometry to support the clean energy transition. DOI: 10.1515/teme-2025-0044

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How is vacuum typically defined in practical terms? Understanding Pressure Reduction for Your Applications

- What technical requirements are placed on heating equipment for fast pyrolysis? Master High-Yield Bio-Oil Production

- What is induction heating and what materials can it be used on? A Guide to Fast, Precise Heating

- Why is precise temperature control in a vacuum drying oven critical for CoTe@Ti3C2 battery electrodes? Key Insights.

- Why is immediate quenching required after CTS treatment of mesoporous carbon? Preserve Your Material’s Atomic Structure

- Why is a high-temperature reaction chamber with a platinum strip used for in-situ XRD analysis of calcium ferrites?

- What are the technological advantages of using a Rapid Thermal Annealing (RTA) system? Precision for Semiconductors

- How do MFCs and Precursor Bottles Work in AP-ALD? Master Precision Vapor Draw for Atomic Coatings