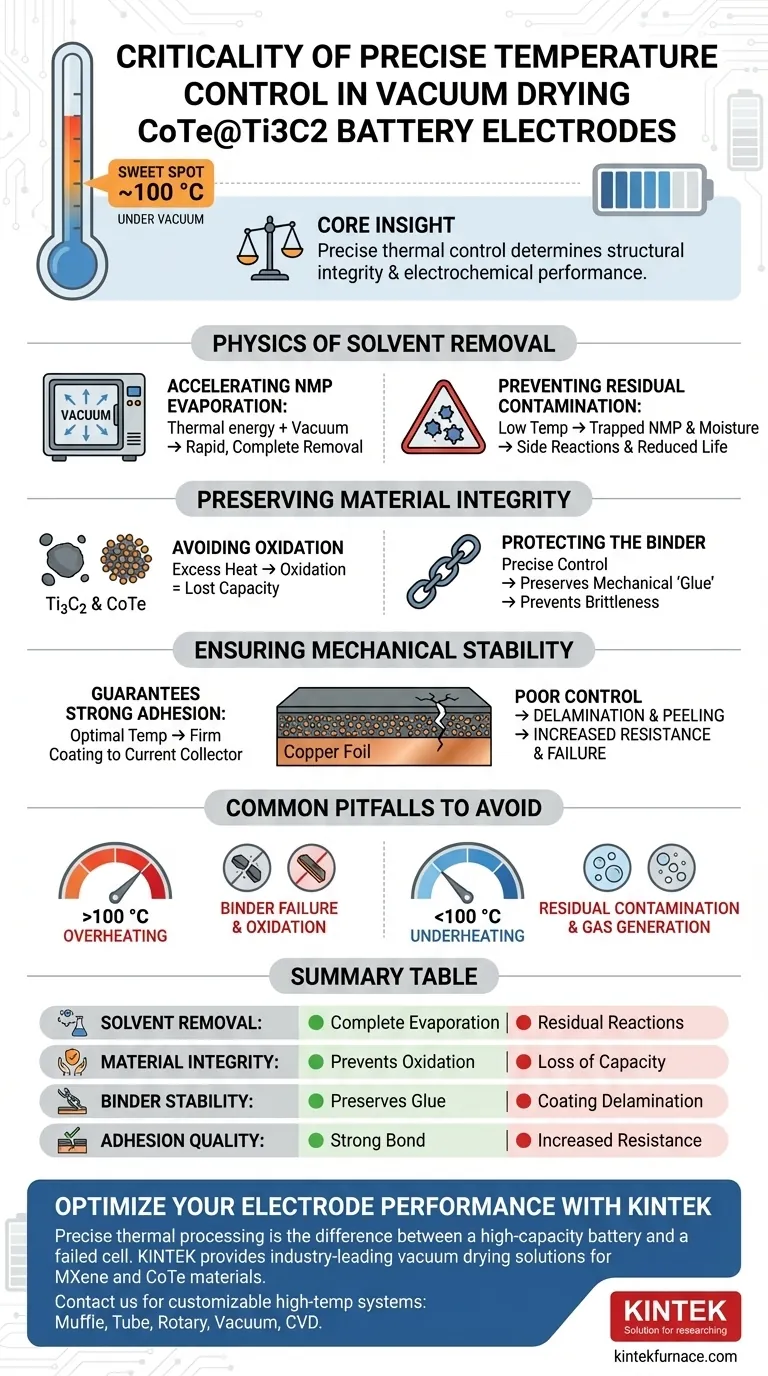

Precise temperature control is the definitive factor in determining both the structural integrity and the electrochemical performance of CoTe@Ti3C2 battery electrodes. It allows for the complete removal of N-Methyl-2-pyrrolidone (NMP) solvents without triggering the thermal degradation of the binder or the oxidation of the active materials.

Core Insight: Successful electrode preparation relies on a thermal "sweet spot"—typically around 100 °C—where the temperature is high enough to drive off solvents and moisture under vacuum, yet low enough to prevent binder failure and oxidation, ensuring the coating adheres firmly to the current collector.

The Physics of Solvent Removal

To understand why precision is non-negotiable, you must first understand the conflicting requirements of the drying process.

Accelerating NMP Evaporation

The primary goal of the vacuum oven is to remove the solvent used in the coating slurry, specifically NMP (N-Methyl-2-pyrrolidone).

While the vacuum environment lowers the boiling point of the solvent, thermal energy is still required to drive the evaporation kinetics. Precise heating ensures this removal is rapid and complete.

Preventing Residual Contamination

If the temperature fluctuates or remains too low, trace amounts of NMP or moisture may remain trapped in the electrode matrix.

Residual solvents and moisture can induce detrimental side reactions during electrolyte injection and subsequent battery cycling, significantly reducing the battery's lifespan.

Preserving Material Integrity

The CoTe@Ti3C2 composite is sensitive to thermal stress. Control over the thermal environment protects the fundamental chemistry of the electrode.

Avoiding Oxidation of Active Materials

Ti3C2 (a MXene) and Cobalt Telluride (CoTe) can be susceptible to oxidation if exposed to excessive heat, even in a vacuum environment.

Strict temperature regulation ensures the material remains chemically active. If oxidation occurs during drying, the electrochemical capacity of the final battery will be permanently compromised before it is even assembled.

Protecting the Binder

The binder is the "glue" that holds the active materials together and secures them to the foil.

Excessive temperatures can cause the binder to degrade or fail. Precise control preserves the binder's mechanical properties, preventing the coating from becoming brittle or detaching.

Ensuring Mechanical Stability

The physical construction of the battery depends on the interface between the coating and the metal foil.

Guarantees Strong Adhesion

The ultimate physical goal of the drying process is strong adhesion between the CoTe@Ti3C2 coating and the copper foil current collector.

If the temperature is not maintained at the optimal set point (typically 100 °C), the electrode coating may delaminate or peel. Poor adhesion leads to increased internal resistance and eventual battery failure.

Common Pitfalls to Avoid

There are distinct trade-offs when temperature control is neglected.

The Risk of Overheating (>100 °C)

Pushing the temperature too high to "speed up" the process is a critical error. This often leads to binder failure and oxidation. The result is a mechanically weak electrode with reduced conductivity.

The Risk of Underheating (<100 °C)

Running the oven too cool fails to fully evacuate the NMP and trace moisture. This residual contamination creates a ticking clock, leading to gas generation and instability once the battery is cycled.

Making the Right Choice for Your Goal

To optimize your drying protocol for CoTe@Ti3C2 electrodes, consider these specific adjustments:

- If your primary focus is Cycle Life: Prioritize extending the drying duration at a highly stable temperature to ensure absolute moisture removal, preventing future side reactions.

- If your primary focus is Mechanical Durability: Focus on staying strictly below the binder's thermal degradation threshold to guarantee maximum adhesion to the copper foil.

Precision in drying is not just about removing liquid; it is about freezing the electrode's chemical potential in its most optimal state.

Summary Table:

| Parameter | Influence on CoTe@Ti3C2 Electrodes | Impact of Poor Control |

|---|---|---|

| Solvent Removal | Complete evaporation of NMP/moisture | Residual NMP causes detrimental side reactions |

| Material Integrity | Prevents MXene (Ti3C2) and CoTe oxidation | Loss of electrochemical capacity and activity |

| Binder Stability | Preserves mechanical "glue" properties | Binder degradation and coating delamination |

| Adhesion Quality | Ensures bond to copper foil current collector | Increased internal resistance and battery failure |

| Optimal Temp | Typically maintained at 100 °C under vacuum | Overheating leads to brittle, inactive materials |

Optimize Your Electrode Performance with KINTEK

Precise thermal processing is the difference between a high-capacity battery and a failed cell. KINTEK provides industry-leading vacuum drying solutions designed for the sensitive requirements of MXene and CoTe materials.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific lab or production needs. Ensure the integrity of your binders and the activity of your materials with our high-precision technology.

Contact KINTEK today for a customized high-temp solution!

Visual Guide

References

- Ramesh Subramani, Jin‐Ming Chen. Reinforced Capacity and Cycling Stability of CoTe Nanoparticles Anchored on Ti<sub>3</sub>C<sub>2</sub> MXene for Anode Material. DOI: 10.1002/smtd.202500725

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the primary advantages of using powder metallurgy for Ti and TiZr alloys? Achieve Ultimate Structural Precision

- Why is a laboratory vacuum drying oven required for perovskite nanopowders? Safeguard Nanostructure and Purity

- What is a laboratory furnace and why is it important? Unlock Precision Heating for Your Lab

- Why must Ru/GNK catalysts undergo vacuum drying? Ensure Peak Performance with Safe Desorption

- What is the role of high-purity argon gas in ultrafine magnesium powder production? Control Particle Size & Purity

- Why must thermal analysis equipment support multiple heating rates? Key to 5AT & NaIO4 Kinetic Studies

- Why must temperature loss be monitored during the aluminum alloy refining cycle? Essential Tips for Casting Success

- Why must MgO for MKPC be produced at 1600°C? Mastering Chemical Kinetics for High-Performance Modification Slurries