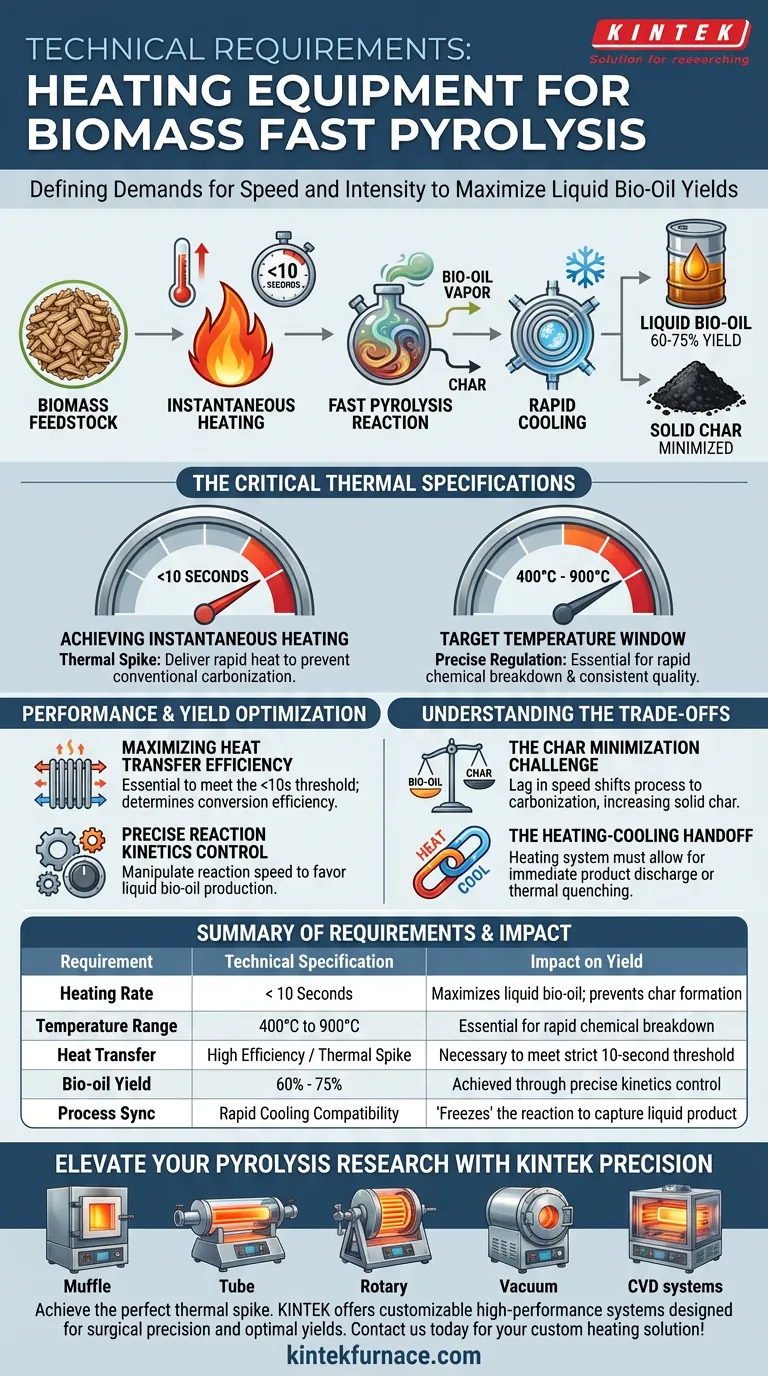

The technical demands for fast pyrolysis heating equipment are defined by speed and intensity. Specifically, the equipment must be capable of raising biomass temperatures to a target range of 400°C to 900°C in less than 10 seconds. This extreme heating rate is the fundamental requirement that distinguishes fast pyrolysis from conventional carbonization processes.

The Core Engineering Challenge To make fast pyrolysis viable, your heating system must offer exceptionally high heat transfer efficiency. The primary goal is not just to heat the material, but to do so instantaneously to maximize liquid bio-oil yields (up to 75%) while strictly limiting the formation of solid char.

The Critical Thermal Specifications

To successfully process biomass into bio-oil, the heating equipment must adhere to rigid thermodynamic parameters.

Achieving Instantaneous Heating

The defining characteristic of this equipment is the ability to deliver a thermal spike.

The system must transfer heat rapidly enough to bring the feedstock to reaction temperature in under 10 seconds. Slow heating will result in conventional pyrolysis, which favors charcoal production rather than the desired liquid fuel.

The Target Temperature Window

The equipment must maintain a precise operating temperature between 400°C and 900°C.

Operating below this range fails to initiate the necessary chemical breakdown. Operating erratically within this range can lead to inconsistent product quality, making precise temperature regulation a non-negotiable requirement.

Performance and Yield Optimization

Beyond raw temperature capabilities, the equipment must be designed for process efficiency and output quality.

Maximizing Heat Transfer Efficiency

High heat transfer efficiency is essential to achieve the required heating rates.

Inefficient systems cannot transfer energy fast enough to meet the 10-second threshold, regardless of how hot the heating element gets. This efficiency is directly linked to the system's ability to convert raw biomass into useful liquid energy.

Precise Reaction Kinetics Control

The equipment must offer granular control over reaction kinetics.

Fast pyrolysis is a delicate chemical balancing act. The heating unit must enable the operator to manipulate the reaction speed to favor the production of liquid bio-oil, which can reach yields of 60% to 75% under optimal conditions.

Understanding the Trade-offs

When selecting or designing heating equipment, you must balance speed with control to avoid common process failures.

The Char Minimization Challenge

The primary trade-off in fast pyrolysis is between bio-oil yield and solid char generation.

If the heating equipment lags even slightly in heat transfer speed, the process shifts toward carbonization. This results in the "minimizing" of bio-oil and a significant increase in solid char, effectively defeating the purpose of fast pyrolysis.

The Heating-Cooling Handoff

While this analysis focuses on heating, the equipment must be compatible with a rapid cooling stage.

The reference emphasizes that instantaneous heating is "followed by rapid cooling." Therefore, the heating equipment must allow for immediate product discharge or thermal quenching to "freeze" the reaction and capture the bio-oil.

Making the Right Choice for Your Goal

To maximize the efficiency of your pyrolysis project, align your equipment specifications with your specific yield targets.

- If your primary focus is maximizing liquid bio-oil yield: Prioritize equipment with the highest possible heat transfer coefficient to ensure the biomass reaches 400°C–900°C instantly.

- If your primary focus is process consistency and quality: Ensure the system offers advanced reaction kinetics control to stabilize temperatures and minimize solid char production.

Success in fast pyrolysis relies entirely on the equipment's ability to deliver intense heat with surgical precision.

Summary Table:

| Requirement | Technical Specification | Impact on Yield |

|---|---|---|

| Heating Rate | < 10 Seconds | Maximizes liquid bio-oil; prevents char formation |

| Temperature Range | 400°C to 900°C | Essential for rapid chemical breakdown |

| Heat Transfer | High Efficiency/Thermal Spike | Necessary to meet strict 10-second threshold |

| Bio-oil Yield | 60% - 75% | Achieved through precise kinetics control |

| Process Sync | Rapid Cooling Compatibility | "Freezes" the reaction to capture liquid product |

Elevate Your Pyrolysis Research with KINTEK Precision

Achieving the perfect thermal spike is the difference between high-value bio-oil and low-grade char. At KINTEK, we specialize in the engineering excellence required for fast pyrolysis. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your specific heating rates and temperature windows.

Don't let inefficient heat transfer limit your yields. Partner with KINTEK to access advanced laboratory high-temperature furnaces designed for surgical precision. Contact us today to discuss your custom heating solution!

Visual Guide

References

- Jean de Dieu Marcel Ufitikirezi, Luboš Smutný. Agricultural Waste Valorization: Exploring Environmentally Friendly Approaches to Bioenergy Conversion. DOI: 10.3390/su16093617

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the key requirements for steel materials in high-speed rail, nuclear power, and aerospace industries? Unlock High-Performance Steel Solutions

- What are the advantages of solution combustion synthesis? Optimize (MnFeNiCoX)3O4 High-Entropy Oxide Catalyst Production

- What is preventive maintenance on a furnace? A Proactive Strategy for Peak Performance

- What are the key characteristics of furnaces used in 3D printing sintering? Achieve Precision Sintering for High-Quality Parts

- What are some examples of low-temperature industrial heating processes? Boost Efficiency and Sustainability

- How does a magnetic stirring hot plate contribute to sol-gel synthesis? Expert Guide to Precursor Thin Film Success

- Why are automated Mass Flow Controllers (MFCs) essential in mixed-gas nitriding? Achieve Process Precision

- Why is a nitrogen (N2) purging system necessary for biomass torrefaction? Prevent Combustion and Maximize Biochar Yield