In short, preventive furnace maintenance is a scheduled, proactive service designed to keep your heating system running at peak efficiency and to identify potential problems before they lead to a breakdown. It involves a detailed inspection, cleaning, and adjustment of your furnace's key components.

Preventive maintenance is not merely a cleaning service; it is a strategic investment in your system's reliability, safety, and efficiency. It shifts your approach from reactive emergency repairs to proactive system care.

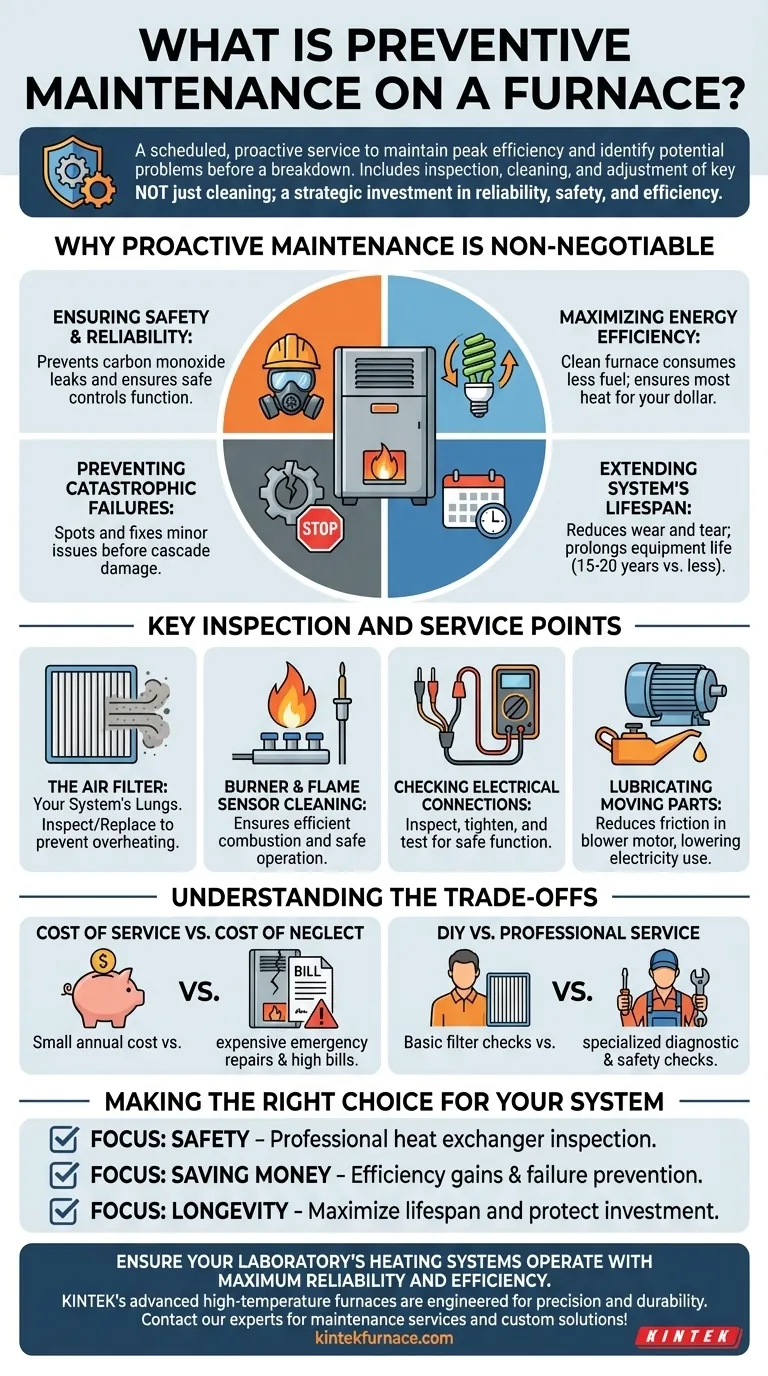

Why Proactive Maintenance is Non-Negotiable

Failing to service your furnace is like never changing the oil in your car. While it may run for a while, you are drastically shortening its lifespan and guaranteeing an expensive, inconvenient failure down the line.

Ensuring Safety and Reliability

A primary goal of a tune-up is safety. A technician will inspect the heat exchanger for cracks, which can leak dangerous carbon monoxide gas into your home. They also ensure all safety controls are functioning correctly, giving you peace of mind that the system will operate reliably when temperatures drop.

Maximizing Energy Efficiency

A clean furnace is an efficient furnace. Over time, dust and debris accumulate on critical parts like burners and blower components, forcing the system to work harder and consume more fuel to produce the same amount of heat. Regular cleaning and calibration ensure you get the most heat for your energy dollar.

Preventing Catastrophic Failures

Most major furnace failures—like a cracked heat exchanger or a burned-out motor—begin as small, correctable issues. A technician can spot a worn belt, a failing capacitor, or a dirty flame sensor and fix it for a minor cost, preventing a cascade of damage that could lead to a system-wide failure and a multi-thousand-dollar replacement.

Extending the System's Lifespan

The typical furnace is designed to last 15-20 years, but this lifespan is entirely dependent on proper maintenance. The mechanical stress caused by dirt, friction, and loose connections accelerates wear and tear on every component, significantly reducing the return on your initial investment.

Key Inspection and Service Points

A professional maintenance call is a comprehensive process. While the exact checklist may vary, it always covers these core areas.

The Air Filter: Your System's Lungs

The technician will inspect and, if necessary, replace your air filter. A clogged filter is the single most common cause of furnace problems, as it restricts airflow, causing the system to overheat and components to fail prematurely.

Burner and Flame Sensor Cleaning

Dirty burners can lead to inefficient and incomplete fuel combustion. The flame sensor, a critical safety device, can become coated with residue and fail to detect a flame, causing the furnace to shut down. Cleaning both ensures efficient, safe operation.

Checking Electrical Connections

Loose or corroded electrical connections can cause intermittent failures or lead to a complete system shutdown. A technician will inspect and tighten all wiring and test electrical components like capacitors and relays to ensure they are within their operational specifications.

Lubricating Moving Parts

Your furnace contains several moving parts, most importantly the blower motor. Proper lubrication reduces friction, which in turn lowers electricity consumption and prevents the motor from seizing up under strain.

Understanding the Trade-offs

Making an informed decision requires looking at both the costs and the benefits objectively.

The Cost of Service vs. The Cost of Neglect

An annual maintenance plan has an upfront cost. However, this cost is minimal when compared to the expense of an emergency service call on a holiday weekend, a significantly higher monthly energy bill due to inefficiency, or the premature replacement of the entire system.

DIY vs. Professional Service

A homeowner can and should handle basic tasks like inspecting and changing the air filter every 1-3 months. However, tasks involving the gas valve, electrical systems, and internal combustion components require specialized tools and diagnostic training. Attempting to service these yourself poses a significant safety risk.

Making the Right Choice for Your System

Annual maintenance is universally recommended, but your primary motivation may shape how you view its benefits.

- If your primary focus is safety: The inspection of the heat exchanger and combustion system to prevent carbon monoxide leaks makes professional service an essential annual task.

- If your primary focus is saving money: The efficiency gains and prevention of costly emergency repairs mean that annual maintenance consistently delivers a positive financial return.

- If your primary focus is system longevity: Think of maintenance as the single most effective action you can take to maximize the lifespan of your furnace and protect your investment.

Ultimately, preventive maintenance transforms your furnace from a potential liability into a reliable asset you can count on.

Summary Table:

| Key Aspect | Benefit |

|---|---|

| Safety Inspection | Prevents carbon monoxide leaks and ensures safe operation. |

| Efficiency Tune-up | Reduces energy consumption and lowers utility bills. |

| Failure Prevention | Identifies minor issues before they cause catastrophic failure. |

| Lifespan Extension | Maximizes the return on your investment by protecting the system. |

Ensure your laboratory's heating systems operate with maximum reliability and efficiency. KINTEK's advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are engineered for precision and durability. Leverage our exceptional R&D and deep customization capabilities to get a furnace solution that perfectly meets your unique experimental requirements. Protect your investment and avoid costly downtime—contact our experts today for a consultation on our maintenance services and custom furnace solutions!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production