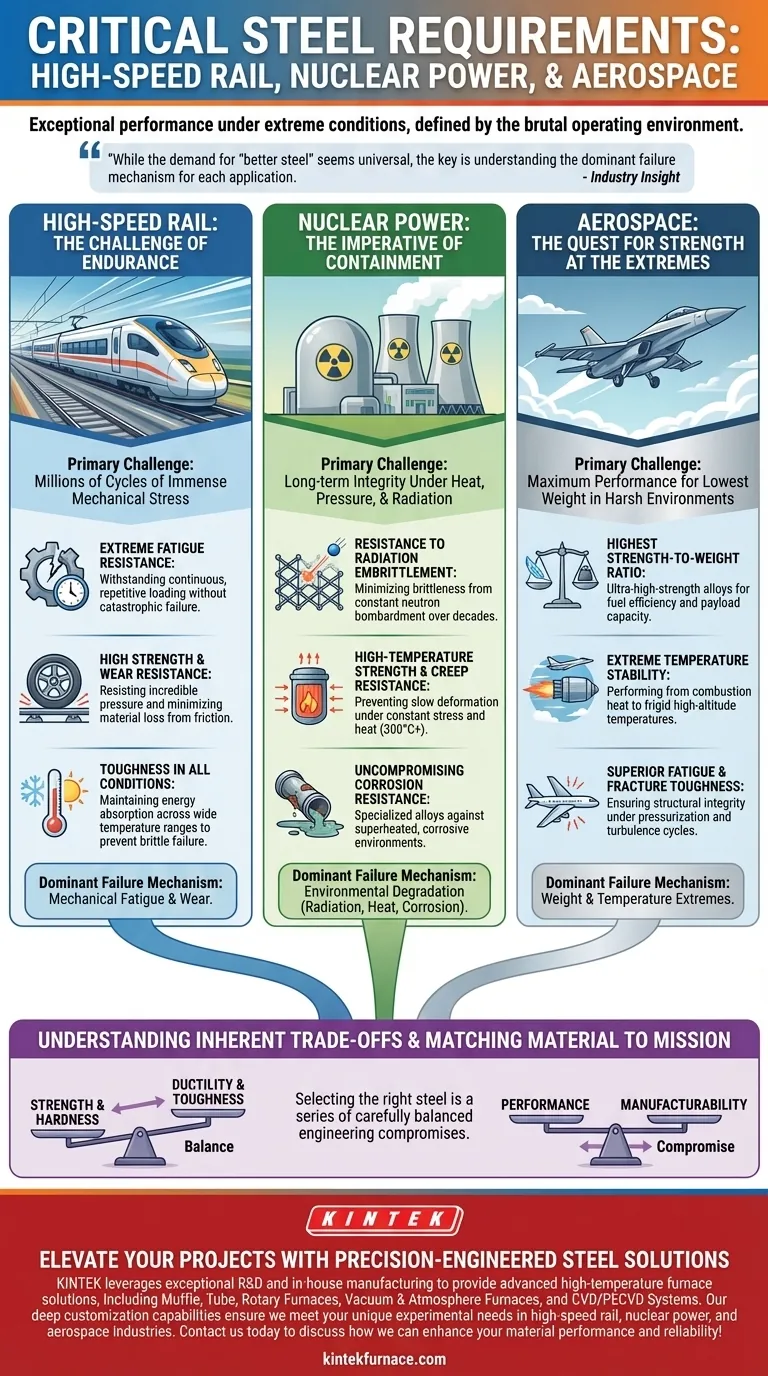

At their core, the steel materials required for high-speed rail, nuclear power, and aerospace must all deliver exceptional performance under extreme conditions. While they share common needs for high strength, fatigue resistance, and corrosion control, the specific priority and combination of these properties are uniquely defined by the brutal operating environment of each industry.

While the demand for "better steel" seems universal, the key is understanding the dominant failure mechanism for each application. High-speed rail battles mechanical fatigue, nuclear power fights environmental degradation from radiation and heat, and aerospace is a constant struggle against weight and temperature extremes.

High-Speed Rail: The Challenge of Endurance

The primary challenge for steel in high-speed rail is withstanding millions of cycles of immense mechanical stress. The focus is on long-term durability and predictability to ensure safety over decades of service.

Extreme Fatigue Resistance

Components like axles, wheels, and rails are subjected to continuous, repetitive loading and unloading. Steels used here must have exceptional fatigue strength to resist the initiation and growth of microscopic cracks that could lead to catastrophic failure.

High Strength and Wear Resistance

The point of contact between the wheel and the rail experiences incredible pressure. The steel must possess high yield strength to avoid permanent deformation and excellent wear resistance to minimize material loss from friction.

Toughness in All Conditions

Rail systems operate in exposed environments, from freezing winters to hot summers. The steel must maintain its toughness (the ability to absorb energy and deform without fracturing) across this entire temperature range to prevent brittle failures.

Nuclear Power: The Imperative of Containment

Steel in the nuclear industry serves a primary role of containment, where failure is not an option. The material must maintain its integrity for over 60 years while being subjected to a unique and punishing combination of heat, pressure, and radiation.

Resistance to Radiation Embrittlement

The constant bombardment by high-energy neutrons inside a reactor core can make steel brittle over time, a phenomenon known as radiation embrittlement. Nuclear-grade steels, particularly for the reactor pressure vessel, are specifically alloyed to minimize this effect and maintain ductility.

High-Temperature Strength and Creep Resistance

Reactor components operate at high temperatures (around 300°C / 572°F) and pressures for decades. The steel must resist creep, which is the tendency for a material to slowly deform over time under constant stress and heat.

Uncompromising Corrosion Resistance

The internal components of a reactor are exposed to superheated, high-purity water, a highly corrosive environment. This demands the use of specialized stainless steels or carbon steels clad with a stainless layer to prevent corrosion that could compromise structural integrity.

Aerospace: The Quest for Strength at the Extremes

Aerospace engineering is a battle against gravity. Every component's material is selected to provide the maximum possible performance for the lowest possible weight, all while enduring the harshest operational environments.

The Highest Strength-to-Weight Ratio

This is the most critical metric for aerospace steel. The material must provide immense strength, but every gram is scrutinized to maximize fuel efficiency and payload capacity. Ultra-high-strength (UHS) steel alloys are often used in components like landing gear where other materials lack the requisite strength.

Extreme Temperature Stability

Aerospace steels must perform at both ends of the temperature spectrum. Engine components and fasteners must withstand the extreme heat of combustion and exhaust, while structural airframe parts must retain their toughness and not become brittle at the frigid temperatures of high-altitude flight.

Superior Fatigue and Fracture Toughness

An airframe is subjected to cycles of stress from pressurization, turbulence, and landings. The materials must have excellent fatigue life and high fracture toughness, ensuring that if a small crack does form, it will not propagate rapidly to a critical failure.

Understanding the Inherent Trade-offs

Selecting the right steel is never about finding a single "best" alloy. It is always a series of carefully balanced engineering compromises.

Strength vs. Ductility

Generally, as you increase the strength and hardness of a steel alloy, you decrease its ductility and toughness. A very hard steel might resist wear but could be more prone to shattering under a sudden impact.

Performance vs. Manufacturability

The most advanced, highest-performing alloys are often the most difficult to work with. They can be challenging to weld, machine, or form, which significantly increases manufacturing complexity and cost.

The "No Single Solution" Principle

Even within a single system, material needs vary dramatically. A jet engine's turbine blades require extreme creep resistance at high temperatures, while its outer casing needs strength and containment capability. Each part demands a different, specialized alloy.

Matching the Material to the Mission

Your choice of material must be guided by the primary operational demand and the most likely point of failure.

- If your primary focus is mechanical endurance and cyclic loading: Prioritize steels with proven high-cycle fatigue resistance and wear characteristics, as required in high-speed rail.

- If your primary focus is long-term stability in a harsh, sealed environment: Select materials engineered for resistance to radiation, high-temperature creep, and corrosion, as seen in nuclear power.

- If your primary focus is maximizing performance while minimizing weight: Target ultra-high-strength steels with an exceptional strength-to-weight ratio and stability across extreme temperature ranges, which is the core of aerospace design.

Understanding these specific demands is the essential first step toward ensuring safety, reliability, and innovation in these critical fields.

Summary Table:

| Industry | Key Requirements | Primary Challenges |

|---|---|---|

| High-Speed Rail | Fatigue resistance, high strength, wear resistance, toughness | Mechanical stress, cyclic loading, temperature variations |

| Nuclear Power | Radiation resistance, creep resistance, corrosion resistance | Long-term stability, high temperatures, radiation embrittlement |

| Aerospace | High strength-to-weight ratio, temperature stability, fatigue and fracture toughness | Weight minimization, extreme temperature ranges, cyclic stress |

Ready to elevate your projects with precision-engineered steel solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental needs in high-speed rail, nuclear power, and aerospace industries. Contact us today to discuss how we can enhance your material performance and reliability!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment