At their core, furnaces designed for 3D printing sintering are defined by a few critical capabilities. These are not simple ovens, but highly engineered systems built for precise thermal and atmospheric control. Their primary characteristics include the ability to maintain uniform high temperatures, create a specific atmosphere (such as a vacuum or inert gas), and operate safely and efficiently to produce dense, high-quality metal or ceramic parts.

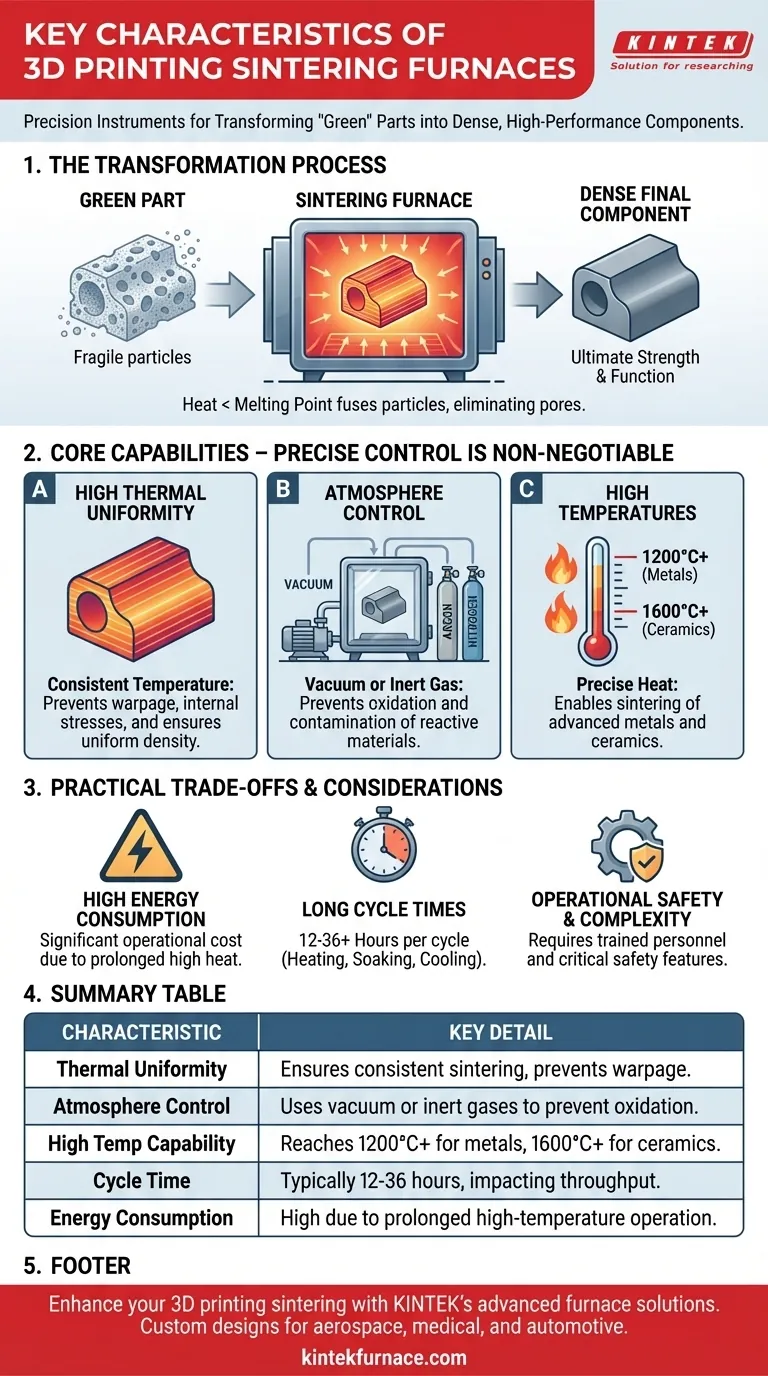

A sintering furnace is a precision instrument engineered to solve one central problem: transforming a fragile, porous 3D printed "green" part into a dense, high-performance final component. Every key feature exists to control heat and chemistry with extreme accuracy, as this transformation is where a printed object gains its ultimate strength and function.

Why Precise Environmental Control is Non-Negotiable

The success of sintering hinges on creating a perfect, repeatable environment. Even small deviations can lead to failed parts, making precise control the most important aspect of a sintering furnace.

Achieving High Thermal Uniformity

Consistent temperature across the entire part is critical. Thermal uniformity ensures that all areas of the component sinter at the same rate.

Without it, you risk internal stresses, warpage, and inconsistent density. This leads to parts that fail to meet mechanical specifications.

The Role of Atmosphere Control

Sintering happens at extremely high temperatures, where materials like metal powders are highly reactive to oxygen. Atmosphere control is essential to prevent oxidation and contamination.

Furnaces achieve this in two primary ways: by creating a vacuum to remove air or by flooding the chamber with an inert gas like argon or nitrogen. This protects the material's integrity and ensures the final part has the desired chemical and mechanical properties.

Reaching High Temperatures for Advanced Materials

Different materials require different sintering temperatures. Stainless steels may sinter around 1200°C, while advanced ceramics can require temperatures well over 1600°C.

A key characteristic of a sintering furnace is its ability to safely and consistently reach the high temperatures needed for the specific metal or ceramic powders being used in industries like aerospace, medical, and automotive.

From Fragile Powder to Functional Part

A sintering furnace is the final, critical step in many powder-based 3D printing workflows. It's where the printed object becomes a functional component.

The Sintering Process in Context

Sintering is a process where compacted powder is heated to a temperature just below its melting point. At this temperature, the particles fuse together, eliminating the pores between them and forming a solid, dense object.

In 3D printing workflows like binder jetting, the initial printed part (the "green" part) is brittle. The sintering furnace provides the necessary heat treatment to give it its final strength.

Enabling Production of Critical Components

The precision of a sintering furnace is what allows for the creation of complex, high-strength parts for demanding applications.

This includes manufacturing wear-resistant ceramic components or dense, isotropic metal parts for medical implants, aerospace brackets, and automotive engine components.

Understanding the Practical Trade-offs

While essential, integrating a sintering furnace into a workflow involves important considerations regarding cost, time, and safety.

High Energy Consumption

Reaching and holding temperatures above 1200°C for many hours is an energy-intensive process. The operational cost, primarily electricity and process gases, is a significant factor in the total cost per part.

Long Cycle Times

A full sintering cycle includes heating, soaking at a specific temperature, and cooling. This entire process can take anywhere from 12 to 36 hours, or even longer. This cycle time is a primary bottleneck that directly impacts overall production throughput.

Operational Safety and Complexity

These are powerful industrial machines. Essential safety features like over-temperature protection, emergency shut-off mechanisms, and clear alarms are not optional. Operating these furnaces requires trained personnel who understand the risks associated with high temperatures and controlled atmospheres.

Making the Right Choice for Your Application

Selecting a furnace requires matching its capabilities to your specific manufacturing goals.

- If your primary focus is research and material development: Prioritize a furnace with maximum flexibility, offering a wide temperature range and options for different process gases to test new materials.

- If your primary focus is high-volume production: Emphasize efficiency, reliability, and features that maximize throughput, such as faster cooling cycles or automation integration.

- If your primary focus is standard metal parts (e.g., steel): Select a robust furnace with a proven track record for your specific material, as extreme temperature capabilities may be unnecessary and add cost.

Ultimately, selecting the right furnace is about matching its precision engineering to the performance demands of your final part.

Summary Table:

| Characteristic | Key Details |

|---|---|

| Thermal Uniformity | Ensures consistent sintering, prevents warpage and internal stresses |

| Atmosphere Control | Uses vacuum or inert gases (e.g., argon, nitrogen) to prevent oxidation |

| High Temperature Capability | Reaches 1200°C+ for metals and 1600°C+ for ceramics |

| Safety Features | Includes over-temperature protection and emergency shut-offs |

| Cycle Time | Typically 12-36 hours, impacting production throughput |

| Energy Consumption | High due to prolonged high-temperature operation |

Ready to enhance your 3D printing sintering process? KINTEK specializes in advanced high-temperature furnace solutions tailored for industries like aerospace, medical, and automotive. Leveraging our exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental and production needs. Contact us today to discuss how our furnaces can deliver superior performance and efficiency for your lab!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety