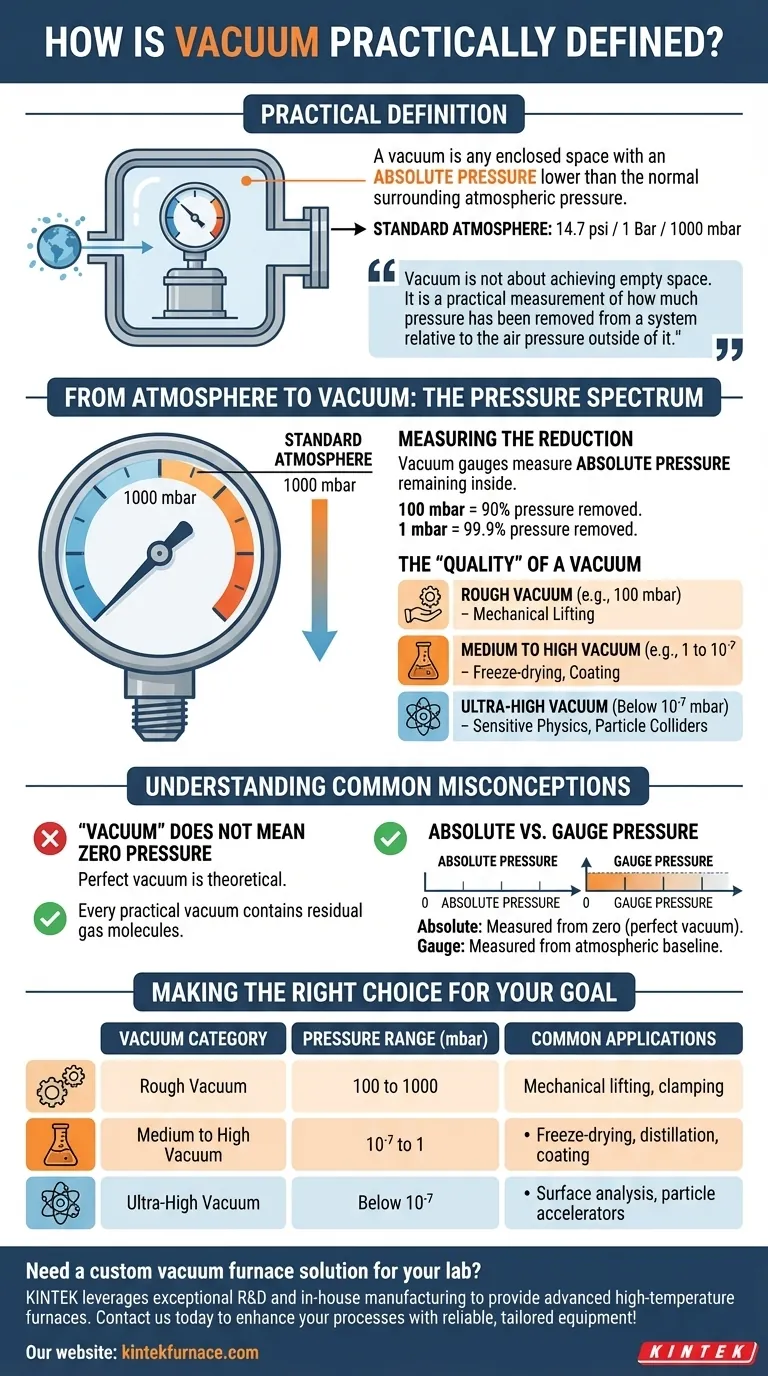

In practical terms, a vacuum is any enclosed space with an absolute pressure lower than the normal surrounding atmospheric pressure. This baseline atmospheric pressure is standardized at sea level as 14.7 pounds per square inch (psi), which is commonly rounded to 1 Bar or 1000 millibars (mbar) for technical work.

The critical insight is that vacuum is not about achieving "empty space." It is a practical measurement of how much pressure has been removed from a system relative to the air pressure outside of it.

From Atmosphere to Vacuum: The Pressure Spectrum

To understand vacuum, you must first understand the pressure you are starting from. All practical vacuum measurements are relative to the blanket of air surrounding us.

Defining the Starting Point: Standard Atmosphere

The air in our atmosphere exerts pressure on everything. This is called atmospheric pressure.

This pressure is the benchmark against which a vacuum is measured. It is defined as 1 atmosphere (atm), which is equivalent to approximately 1000 millibars (mbar).

Measuring the Reduction: The Role of the Gauge

Vacuum gauges do not measure "emptiness." They measure the absolute pressure remaining inside a sealed chamber.

When a gauge reads 100 mbar, it means 90% of the air pressure has been removed. A reading of 1 mbar indicates that 99.9% of the pressure has been removed.

The "Quality" of a Vacuum

The term "vacuum" covers a vast range of pressures. In engineering and science, vacuums are categorized by quality, from rough to ultra-high.

A rough vacuum (e.g., 100 mbar) might be used for mechanical lifting, while an ultra-high vacuum (below 10⁻⁷ mbar) is required for sensitive physics experiments to minimize particle collisions.

Understanding Common Misconceptions

The practical definition of vacuum often leads to a few key points of confusion. Clarifying these is essential for any technical application.

"Vacuum" Does Not Mean Zero Pressure

Achieving a perfect vacuum—a space with zero pressure and zero particles—is a theoretical concept that is practically impossible.

Every practical vacuum contains residual gas molecules. The "quality" of the vacuum simply describes how few of these molecules are left.

Absolute vs. Gauge Pressure

It is critical to distinguish between absolute pressure and gauge pressure.

Absolute pressure is measured from a baseline of zero (a perfect vacuum). Gauge pressure is measured from a baseline of the surrounding atmospheric pressure. Vacuum is almost always discussed in terms of absolute pressure to provide a stable, universal reference point.

Making the Right Choice for Your Goal

The level of vacuum you need is dictated entirely by your application. Different processes require vastly different degrees of pressure reduction.

- If your primary focus is mechanical work (clamping, lifting): A rough or low vacuum (from 900 mbar down to 1 mbar) is almost always sufficient.

- If your primary focus is process engineering (freeze-drying, distillation, coating): A medium to high vacuum (from 1 mbar down to 10⁻⁷ mbar) is typically required to control chemical and physical processes.

- If your primary focus is fundamental science (surface analysis, particle accelerators): An ultra-high vacuum (below 10⁻⁷ mbar) is necessary to create a near-perfectly isolated environment.

Ultimately, defining the required pressure level is the first step in engineering any successful vacuum system.

Summary Table:

| Vacuum Category | Pressure Range (mbar) | Common Applications |

|---|---|---|

| Rough Vacuum | 100 to 1000 | Mechanical lifting, clamping |

| Medium to High Vacuum | 10⁻⁷ to 1 | Freeze-drying, distillation, coating |

| Ultra-High Vacuum | Below 10⁻⁷ | Surface analysis, particle accelerators |

Need a custom vacuum furnace solution for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental requirements. Contact us today to enhance your processes with reliable, tailored equipment!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?