Carbon coating processes and specialized heat treatment are not optional add-ons; they are fundamental necessities for stabilizing silicon-based anode materials. By utilizing equipment like tube furnaces to thermally decompose precursors such as coal tar pitch, manufacturers create a uniform conductive skin around silicon particles. This layer is the primary mechanism for mitigating silicon’s inherent weaknesses—specifically its poor conductivity and massive volume expansion—thereby enabling high-performance battery operation.

Silicon has immense potential but suffers from structural instability during charging. Carbon coating acts as a stabilizing interface that enhances electron flow and physically contains the silicon, transforming a volatile material into a durable battery component.

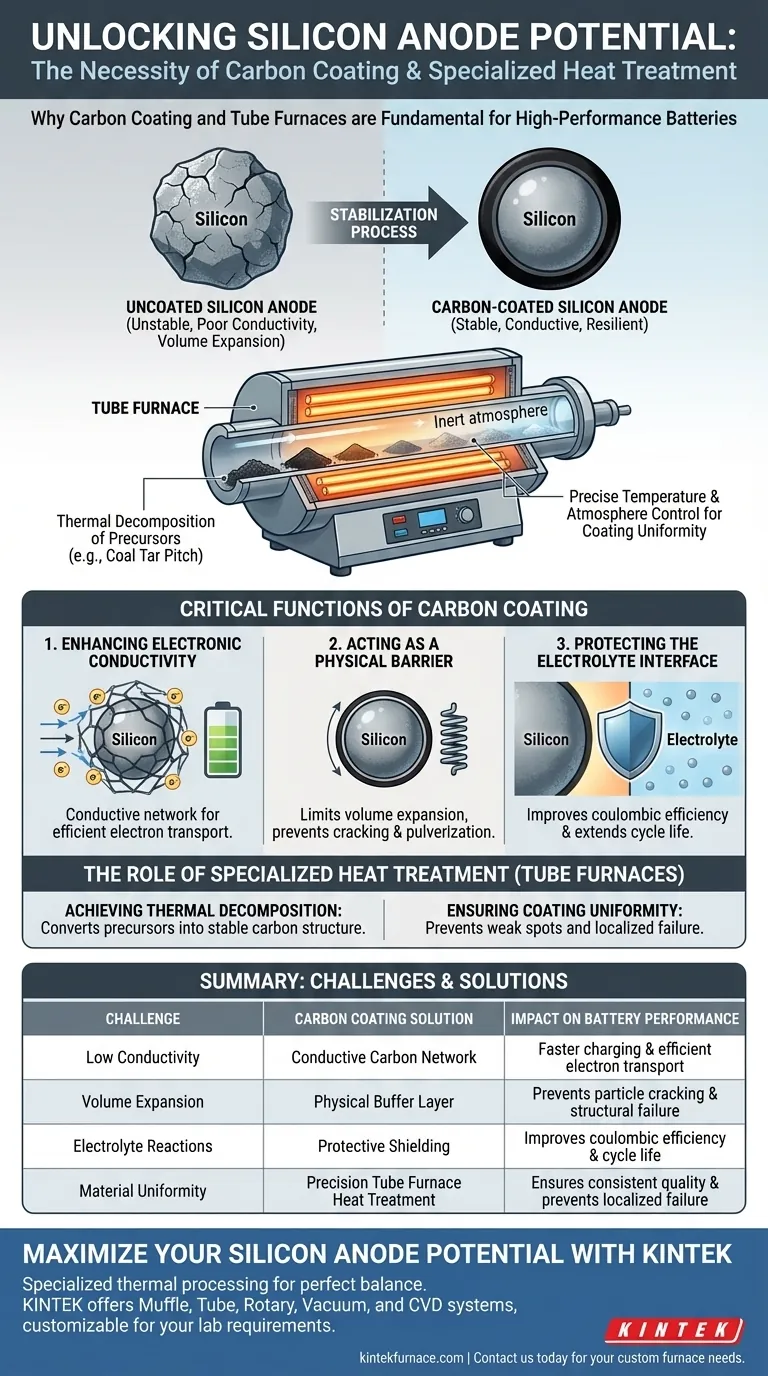

The Critical Functions of Carbon Coating

To understand why this process is necessary, you must look at the specific failures that occur in uncoated silicon anodes. The carbon layer addresses three distinct physical and chemical challenges.

Enhancing Electronic Conductivity

Silicon is a semiconductor, meaning its natural ability to transport electrons is relatively low compared to traditional graphite anodes.

Carbon coating creates a highly conductive network across the surface of the composite particles. This ensures efficient electron transport during rapid charging and discharging cycles.

Acting as a Physical Barrier

One of the most significant challenges with silicon is that it swells dramatically when absorbing lithium ions.

The carbon layer serves as a rigid but resilient buffer. It limits the volume expansion of the active silicon substances, preventing the particle from cracking or pulverizing under stress.

Protecting the Electrolyte Interface

When raw silicon comes into direct contact with battery electrolytes, it often causes unwanted side reactions.

The carbon coating acts as a shield, reducing direct contact between the active silicon and the electrolyte. This preservation of the interface improves coulombic efficiency (the efficiency of electron transfer) and extends the overall cycle life of the battery.

The Role of Specialized Heat Treatment

The quality of the carbon coating is entirely dependent on the precision of the thermal processing. This is where equipment like tube furnaces becomes essential.

Achieving Thermal Decomposition

You cannot simply "paint" carbon onto silicon. The process requires the thermal decomposition of carbon-rich precursors, such as coal tar pitch.

Tube furnaces provide the controlled high-temperature environment necessary to break down these precursors and convert them into a stable, solid carbon structure.

Ensuring Coating Uniformity

For the anode to function reliably, the carbon layer must be uniform across every particle.

Specialized heat treatment equipment allows for precise control over temperature gradients and atmosphere. This ensures the carbon layer forms evenly, preventing weak spots that could lead to localized failure or swelling.

Understanding the Trade-offs

While carbon coating is necessary, it introduces specific variables that must be managed to maintain material performance.

Process Complexity vs. Performance

Implementing high-temperature carbonization adds steps to the manufacturing workflow.

Using tube furnaces increases energy consumption and processing time compared to simpler production methods. However, this "cost" is unavoidable for achieving the stability required for high-performance applications.

Balancing the Layer Thickness

The carbon layer must be thick enough to provide protection but thin enough not to impede lithium ion movement.

If the decomposition process is not controlled, an excessively thick carbon layer could reduce the overall specific capacity of the anode, negating the benefits of using silicon in the first place.

Making the Right Choice for Your Goal

When designing your production process for silicon-based anodes, your heat treatment strategy should align with your specific performance targets.

- If your primary focus is Cycle Life: Prioritize coating uniformity and structural integrity to ensure the carbon barrier can withstand repeated volume expansion without cracking.

- If your primary focus is High-Rate Capability: Focus on the quality of the carbon precursor and decomposition temperature to maximize the electronic conductivity of the surface layer.

Mastering the carbon coating process is the definitive step in bridging the gap between raw silicon potential and a commercially viable energy storage solution.

Summary Table:

| Challenge | Carbon Coating Solution | Impact on Battery Performance |

|---|---|---|

| Low Conductivity | Conductive Carbon Network | Faster charging & efficient electron transport |

| Volume Expansion | Physical Buffer Layer | Prevents particle cracking & structural failure |

| Electrolyte Reactions | Protective Shielding | Improves coulombic efficiency & cycle life |

| Material Uniformity | Precision Tube Furnace Heat Treatment | Ensures consistent quality & prevents localized failure |

Maximize Your Silicon Anode Potential with KINTEK

Precise carbon coating requires specialized thermal processing to achieve the perfect balance of conductivity and structural resilience. At KINTEK, we understand the nuances of battery material innovation.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique high-temperature lab requirements. Whether you are optimizing coal tar pitch decomposition or scaling up silicon-carbon composite production, our systems provide the uniform temperature control necessary for superior performance.

Ready to elevate your energy storage research? Contact us today to discuss your custom furnace needs with our technical team.

Visual Guide

References

- Hyunsik Yoon, Hansu Kim. Magnesiated Si‐Rich SiO<sub><i>x</i></sub> Materials for High‐Performance Lithium‐Ion Batteries. DOI: 10.1002/batt.202500473

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the role of an industrial high-speed ball mill in kaolin pretreatment? Enhance Reactivity & Surface Area

- What are the methods of heat transfer in furnaces? Master Heat Control for Better Results

- What is the significance of programmed temperature control in TiO2 thin film conversion? Master Structural Precision

- Why must the casting dispersion be treated in a 100°C drying oven? Ensure Perfect Film Morphology

- Why is a high-precision substrate heating system required for BST thin films? Achieve Crystal Growth Success

- How does Plasma Flash Sintering (PFS) equipment enable the stabilization of metastable phases? Defy Thermal Limits

- How does oxygen flow at 2 to 8 SLPM regulate PS-PVD coating quality? Master Thermal Barrier Integrity

- What are the three main categories of thin-film deposition methods? Essential Guide for Material Engineers