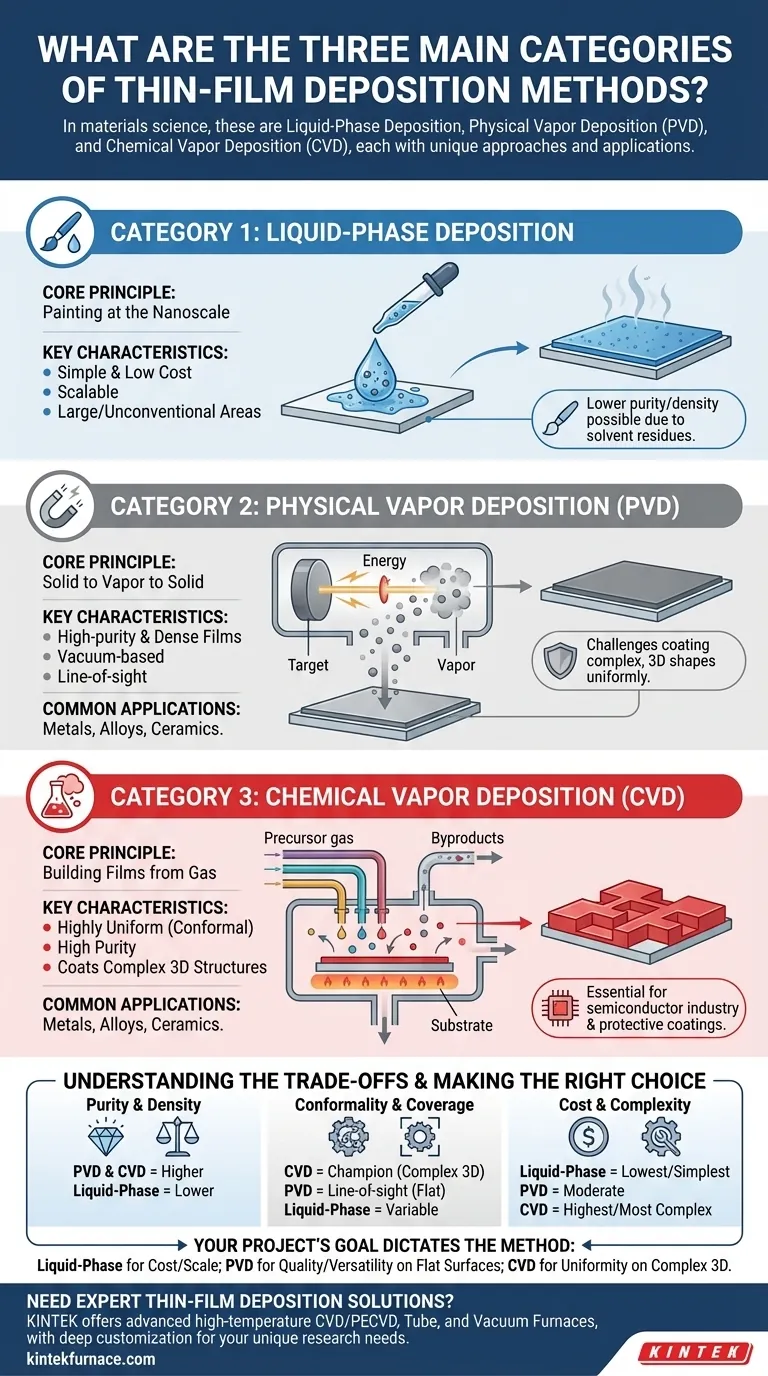

In materials science and engineering, the three primary categories of thin-film deposition are liquid-phase deposition, Physical Vapor Deposition (PVD), and Chemical Vapor Deposition (CVD). Each category represents a fundamentally different approach to transforming a source material into an ultra-thin layer on a substrate, dictating the film's properties, cost, and applications.

The choice between these methods is not arbitrary; it's a critical engineering decision. The core distinction lies in the starting phase of the material and how it is transported to the surface: painted from a liquid, condensed from a physical vapor, or synthesized from reactive gases.

A Framework for Understanding Deposition

At its heart, thin-film deposition is the process of adding material, often just a few atoms or molecules thick, onto a solid surface (the substrate). The goal is to create a film with specific electrical, optical, or mechanical properties.

The category of deposition used is defined by the physical state of the source material and the mechanism used to transfer it to the substrate.

Category 1: Liquid-Phase Deposition

The Core Principle: Painting at the Nanoscale

Liquid-phase deposition is the most intuitive category. It involves dissolving or suspending the source material in a liquid solvent to create a chemical solution or suspension.

This solution is then applied to the substrate, and the solvent is evaporated or driven off, leaving behind a thin film of the desired material. Think of it as a highly controlled form of painting or coating.

Key Characteristics

This method is often valued for its simplicity and low cost, as it typically does not require expensive vacuum equipment. It is highly scalable and excellent for coating large or unconventionally shaped areas.

However, films created this way may have lower purity or density compared to vapor-based methods, as solvent residues or impurities can become trapped in the film.

Category 2: Physical Vapor Deposition (PVD)

The Core Principle: Solid to Vapor to Solid

PVD is a vacuum-based process that involves a physical change of state. A solid source material, known as a "target," is bombarded with energy, causing it to transition into a vapor phase.

This vapor then travels through a vacuum chamber and condenses onto the cooler substrate, forming a high-purity thin film. No chemical reactions occur; it is a purely physical transport mechanism.

Key Characteristics

PVD is the workhorse for depositing a wide range of materials, especially metals, alloys, and some ceramics. Common PVD techniques include sputtering and thermal evaporation.

Because it is a "line-of-sight" process, the vapor travels in a straight line from the source to the substrate. This results in high-purity, dense films but can make it difficult to uniformly coat complex, 3D shapes.

Category 3: Chemical Vapor Deposition (CVD)

The Core Principle: Building Films from Gas

CVD is fundamentally different from PVD. Instead of vaporizing a solid, CVD introduces one or more volatile precursor gases into a reaction chamber.

These gases react or decompose on the surface of a heated substrate, chemically forming a new solid material as a thin film. The byproducts of the reaction are then pumped out of the chamber.

Key Characteristics

CVD excels at producing extremely uniform (conformal) and high-purity films. Because the precursor gases can flow around and into complex geometries, CVD can coat intricate 3D structures with near-perfect uniformity.

This property makes CVD indispensable in the semiconductor industry for manufacturing integrated circuits. It is also used for creating durable and protective coatings on tools and other components.

Understanding the Trade-offs

Choosing the right method requires balancing the desired film quality with the practical constraints of cost, material, and substrate geometry.

Purity and Density

PVD and CVD generally produce films with higher purity and density than liquid-phase methods. The vacuum environment minimizes contamination.

Conformality and Coverage

CVD is the champion of conformality, capable of uniformly coating even the most complex topographies. PVD's line-of-sight nature makes this challenging, while liquid-phase methods are variable.

Cost and Complexity

Liquid-phase deposition is typically the least expensive and simplest to implement. PVD represents a moderate investment in vacuum equipment. CVD is often the most complex and expensive due to the need for high temperatures, precursor gas handling, and safety systems.

Material and Temperature

The material you want to deposit is a major constraint. PVD is versatile for most metals and many compounds. CVD is defined by the availability of suitable precursor gases. The high temperatures often required for CVD can also damage heat-sensitive substrates.

Making the Right Choice for Your Application

Your project's goal will point directly to the best deposition category.

- If your primary focus is low-cost, large-area coating where ultimate purity is not critical: Liquid-phase deposition is your most practical and scalable choice.

- If your primary focus is depositing high-purity metals, alloys, or simple ceramics on a relatively flat surface: Physical Vapor Deposition (PVD) offers the best balance of quality and versatility.

- If your primary focus is creating highly uniform, defect-free films on complex 3D structures, especially for electronics: Chemical Vapor Deposition (CVD) is the industry standard and the most capable technology.

Understanding the fundamental difference between these three categories is the first step toward intentionally engineering materials at the atomic scale.

Summary Table:

| Category | Core Principle | Key Characteristics | Common Applications |

|---|---|---|---|

| Liquid-Phase Deposition | Applying a liquid solution to substrate, then evaporating solvent | Simple, low-cost, scalable; may have lower purity | Large-area coatings, cost-sensitive projects |

| Physical Vapor Deposition (PVD) | Vaporizing solid target in vacuum, condensing on substrate | High-purity, dense films; line-of-sight limits complex shapes | Metals, alloys, ceramics on flat surfaces |

| Chemical Vapor Deposition (CVD) | Reacting gases on heated substrate to form solid film | Highly uniform, conformal coatings; high purity and complexity | Semiconductor devices, 3D structures, protective coatings |

Need expert thin-film deposition solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including CVD/PECVD, Tube, and Vacuum & Atmosphere Furnaces. Our deep customization capabilities ensure precise alignment with your unique experimental needs, whether for semiconductor fabrication, materials research, or industrial coatings. Contact us today to enhance your lab's performance and achieve superior results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition