CVD & PECVD Furnace

RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

Item Number : KT-RFPE

Price varies based on specs and customizations

- RF Power

- 0-2000W

- Ultimate Vacuum

- 2×10-4 Pa

- Chamber Dimensions

- Ф420mm × 400 mm

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Reliable PartnerEasy ordering process, quality products, and dedicated support for your business success.

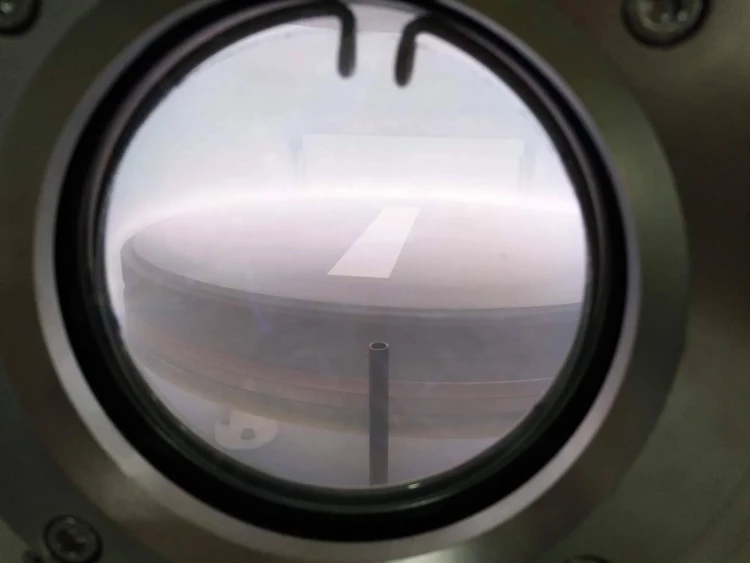

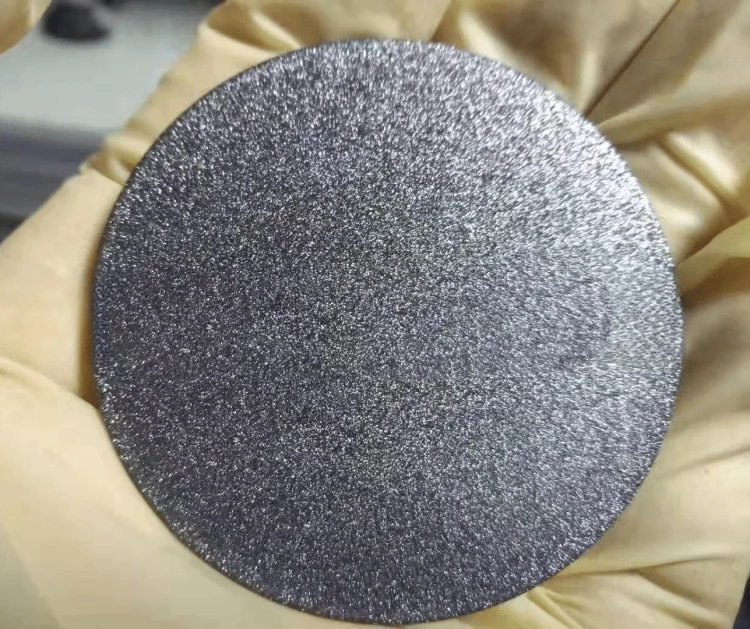

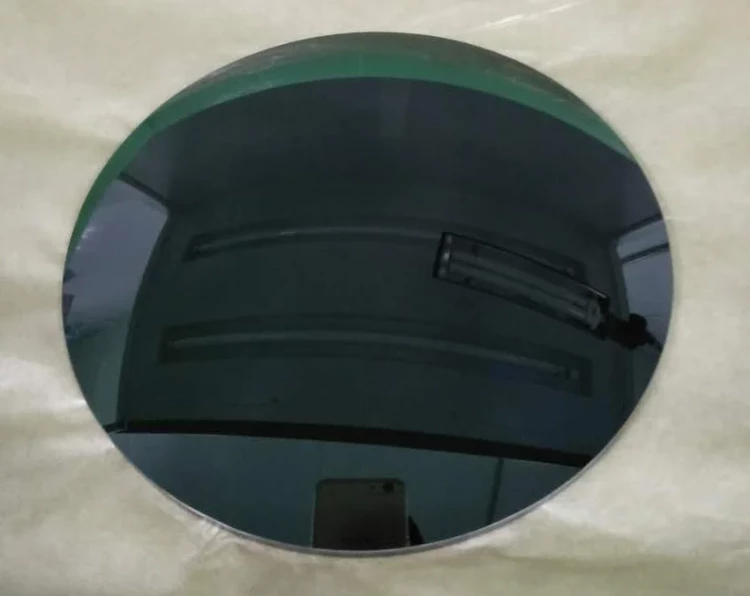

Visual Showcase: RF PECVD System in Detail

Unlock Precision Thin-Film Deposition with KINTEK's RF PECVD Systems

KINTEK's Radio Frequency Plasma-Enhanced Chemical Vapor Deposition (RF PECVD) systems empower diverse laboratories to achieve cutting-edge thin-film deposition. This versatile technique utilizes plasma to precisely deposit a wide array of materials, including metals, dielectrics, and semiconductors, with exceptional control over film thickness, composition, and morphology. Leveraging our exceptional R&D and in-house manufacturing, we deliver advanced RF PECVD solutions tailored to your unique experimental requirements.

Key Applications of RF PECVD

RF-PECVD, a revolutionary technique in the realm of thin-film deposition, finds widespread applications in diverse industries, including:

- Fabrication of optical components and devices

- Manufacturing of semiconductor devices

- Production of protective coatings

- Development of microelectronics and MEMS

- Synthesis of novel materials

Experience Unmatched Control and Efficiency

Our RF PECVD systems are designed to maximize your research outcomes and production efficiency:

Key Features:

- Automated Operation: Simplify your workflow with one-button coating, and process storage and retrieval for consistent, repeatable results.

- Intelligent Control: Benefit from comprehensive process operation logging, proactive alarm functions, and precise signal/valve switching for optimized deposition cycles.

- Reliable Performance: Robust system design including a high-integrity vacuum chamber, efficient pumping system, stable RF source, and precision gas mixing system ensures dependable, long-term operation.

Core Advantages:

- Superior Film Quality: Achieve high-quality film deposition, even at low temperatures suitable for temperature-sensitive substrates.

- Precision & Uniformity: Benefit from precise control over film thickness and composition, with uniform and conformal deposition on complex geometries.

- Clean & Efficient Processing: Experience low particle contamination and high purity films. Our systems are designed as an environmentally friendly process with minimal hazardous waste generation.

- Scalable Solutions: KINTEK's RF PECVD systems are designed for both advanced research and scalable, cost-effective high-volume production.

Robust System Design for Optimal Performance

Our RF PECVD systems are meticulously engineered, comprising a high-vacuum chamber, an efficient vacuum pumping system, precisely controlled cathode and anode targets, a stable RF power source, an advanced inflatable gas mixing system, and a user-friendly computer control cabinet system. This integrated design enables seamless one-button coating, process storage and retrieval, alarm functions, signal and valve switching, comprehensive process operation logging, and reliable deposition of high-quality thin films, such as Diamond-like Carbon (DLC) films on germanium and silicon substrates for applications in the 3-12µm infrared wavelength range.

Technical Specifications

Main equipment part

| Equipment form |

|

| Vacuum chamber |

|

| Host skeleton |

|

| Water cooling system |

|

| Control cabinet |

|

Vacuum system

| Ultimate vacuum |

|

| Restore vacuum time |

|

| Pressure rise rate |

|

| Vacuum system configuration |

|

| Vacuum system measurement |

|

| Vacuum system operation | There are two modes of vacuum manual and vacuum automatic selection;

|

| Vacuum test |

|

Heating system

- Heating method: iodine tungsten lamp heating method;

- Power regulator: digital power regulator;

- Heating temperature: maximum temperature 200°C, power 2000W/220V, controllable and adjustable display, ±2°C control;

- Connection method: fast insertion and quick retrieval, metal shielding cover for anti-fouling, and isolated power supply source to ensure the safety of personnel.

RF radio frequency power supply

- Frequency: RF frequency 13.56MHZ;

- Power: 0-2000W continuously adjustable;

- Function: fully automatic impedance matching function adjustment, fully automatic adjustment to keep the reflection function very low working, internal reflection within 0.5% , with manual and automatic conversion adjustment function;

- Display: with bias voltage, CT capacitor position, RT capacitor position, set power, reflective function display , with communication function, communicate with touch screen, set and display parameters on configuration software, tune line display etc.

Cathode anode target

- Anode target: φ300mm copper substrate is used as the cathode target, the temperature is low when working, and no cooling water is needed;

- Cathode target: φ200mm copper water-cooled cathode target, the temperature is high when working, and the interior is cooled water, to ensure consistent temperature during work, the maximum distance between the anode and the cathode target is 100-250mm.

Inflation control

- Flowmeter: Four-way British flowmeter is used, the flow rate is 0-200SCCM, with pressure display, communication setting parameters, and gas type can be set;

- Stop valve: Qixing Huachuang DJ2C-VUG6 stop valve, works with the flow meter, mixes the gas, fills it into the chamber through the annular inflation device, and flows evenly through the target surface;

- Pre-stage gas storage bottle: mainly a flushing conversion bottle, which vaporizes the C4H10 liquid, and then enters the front-stage pipeline of the flowmeter. The gas storage bottle has a pressure digital display DSP instrument, which performs pressure over pressure and low pressure alarm prompts;

- Mixed gas buffer bottle: The buffer bottle is mixed with four gases in the latter stage. After mixing, it is output from the buffer bottle all the way to the bottom of the chamber and all the way to the top, and one of them can be closed independently;

- Inflating device: the uniform gas pipeline at the outlet of the gas circuit of the chamber body, which is evenly charged to the target surface to make the coating uniform is better.

Control system

- Touch screen: take TPC1570GI touch screen as host computer + keyboard and mouse;

- Control software: tabular process parameter setting, alarm parameter display, vacuum parameter display and curve display, RF power supply and DC direct current power supply parameter setting and display, all valve and switch working state records, process records, alarm records, vacuum record parameters , can be stored for about half a year, and the process operation of the whole equipment is saved in 1 second to save the parameters;

- PLC: Omron PLC is used as the lower computer to collect data of various components and in-position switches, control valves and various components, and then perform data interaction, display and control with configuration software. This is more secure and reliable;

- Control status: one-button coating, automatic vacuuming, automatic constant vacuum, automatic heating, automatic multi-layer process deposition, automatic completion of pick-up and other work;

- Advantages of touch screen: touch screen control software cannot be changed, stable operation is more convenient and flexible, but the amount of stored data is limited, parameters can be directly exported, and when there is a problem with the process;

- Alarm: adopt the sound and light alarm mode, and record the alarm in the configuration alarm parameter library. It can be queried at any time in the future, and the saved data can be queried and called at any time.

Constant vacuum

- Butterfly valve constant vacuum: DN80 butterfly valve cooperates with Inficon CDG025 capacitive film gauge to work constant vacuum, the disadvantage is that the valve port is easy to be polluted and difficult to clean;

- Valve Position Mode: Set the position control mode.

Water, electricity, gas

- The main inlet and outlet pipes are made of stainless steel and equipped with emergency water inlets;

- All water-cooled pipes outside the vacuum chamber adopt stainless steel quick-change fixed joints and plastic high-pressure ( High-quality water pipes, which can be used for a long time without leaking or breaking), and the water inlet and outlet plastic high-pressure water pipes should be displayed in two different colors and correspondingly marked; brand Airtek;

- All water-cooled tubes inside the vacuum chamber are made of high-quality SUS304 material;

- The water and gas circuits are respectively installed with safe and reliable, high-precision display water pressure and air pressure instruments .

- Equipped with 8P chiller for water flow of carbon film machine.

- Equipped with a set of 6KW hot water machine, when the door is opened, hot water will flow through the room.

Security protection requirements

- The machine is equipped with an alarm device;

- When the water pressure or air pressure does not reach the specified flow rate, all vacuum pumps and valves are protected and cannot be started, and an alarm sound and red signal light prompt;

- When the machine is in normal working process, when the water pressure or air pressure is suddenly insufficient, all valves will be automatically closed, and an alarm sound and red signal light will appear;

- When the operating system is abnormal (high voltage, ion source, control system), there will be an alarm sound and a red signal light prompt;

- The high voltage is turned on, and there is a protection alarm device.

Working environment requirements

- Ambient temperature: 10~35℃;

- Relative humidity: not more than 80%;

- The environment around the equipment is clean and the air is clean. There should be no dust or gas that can cause corrosion of electrical appliances and other metal surfaces or cause electrical conduction between metals.

Equipment power requirements

- Water source: industrial soft water, water pressure 0.2~0.3Mpa, water volume~60L/min , water inlet temperature≤25°C; water pipe connection 1.5 inches;

- Air source: air pressure 0.6MPa;

- Power supply: three-phase five-wire system 380V, 50Hz, voltage fluctuation range: line voltage 342 ~ 399V, phase voltage 198 ~ 231V; frequency fluctuation range: 49 ~ 51Hz; equipment power consumption: ~ 16KW; grounding resistance ≤ 1Ω;

- Hoisting requirements: self-provided 3-ton crane, hoisting door not less than 2000X2200mm

Ready to Advance Your Research? Partner with KINTEK.

At KINTEK, we understand that every experiment is unique. Our strong deep customization capability allows us to tailor our RF PECVD systems to your specific requirements. Whether you need modifications to standard models or a completely bespoke solution, our R&D and manufacturing expertise ensures you get the perfect fit for your laboratory.

Discuss your project with our experts today. Fill out our Contact Form, and let's explore how KINTEK can elevate your thin-film deposition capabilities.

FAQ

What Is The Principle Of An MPCVD Machine?

What Is A PECVD Machine Used For?

What Is The Principle Of A CVD Machine?

What Are The Advantages Of Using An MPCVD Machine?

What Are The Main Types Of PECVD Machines?

What Are The Advantages Of Using A CVD Machine?

What Are The Key Applications Of MPCVD Machines?

How Does A PECVD Machine Work?

What Are The Applications Of A CVD Machine?

What Are The Main Components Of An MPCVD Machine?

What Are The Key Features Of A PECVD Machine?

What Are The Key Features Of A CVD Machine?

How Does An MPCVD Machine Enhance Energy Efficiency?

What Are The Advantages Of Using A PECVD Machine?

What Types Of CVD Machines Are Available?

Why Is MPCVD Preferred For Diamond Growth?

What Materials Can Be Deposited Using A PECVD Machine?

Why Is PECVD Preferred Over Other Deposition Methods?

4.9

out of

5

Incredible precision and speed! This system has revolutionized our lab's efficiency.

4.8

out of

5

Top-notch quality and durability. Worth every penny for advanced research.

4.7

out of

5

Fast delivery and easy setup. The technology is cutting-edge and reliable.

4.9

out of

5

Exceptional value for money. The system performs flawlessly under heavy use.

4.8

out of

5

Highly advanced and user-friendly. A game-changer for our semiconductor work.

4.7

out of

5

Impressive durability and performance. Exceeded all our expectations.

4.9

out of

5

The system arrived ahead of schedule and works like a dream. Perfect for high-tech labs.

4.8

out of

5

Precision engineering at its best. This PECVD system is a must-have for serious researchers.

4.7

out of

5

Reliable and efficient. The technology is ahead of its time.

4.9

out of

5

Outstanding performance and quick delivery. Our lab couldn't be happier.

4.8

out of

5

Superior quality and advanced features. A fantastic investment for any lab.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KINTEK Slide PECVD Tube Furnace: Precision thin film deposition with RF plasma, rapid thermal cycling, and customizable gas control. Ideal for semiconductors and solar cells.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

Advanced PECVD Tube Furnace for precise thin film deposition. Uniform heating, RF plasma source, customizable gas control. Ideal for semiconductor research.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

KINTEK's PECVD coating machine delivers precision thin films at low temperatures for LEDs, solar cells & MEMS. Customizable, high-performance solutions.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

KINTEK MPCVD Diamond Machine: High-quality diamond synthesis with advanced MPCVD technology. Faster growth, superior purity, customizable options. Boost production now!

Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

Ultra-Vacuum Electrode Feedthroughs for reliable UHV connections. High-sealing, customizable flange options, ideal for semiconductor & space applications.

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

KINTEK MPCVD Systems: Grow high-quality diamond films with precision. Reliable, energy-efficient, and beginner-friendly. Expert support available.

MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

KINTEK MPCVD Systems: Precision diamond growth machines for high-purity lab-grown diamonds. Reliable, efficient, and customizable for research and industry.

Spark Plasma Sintering SPS Furnace

Discover KINTEK's advanced Spark Plasma Sintering (SPS) Furnace for rapid, precise material processing. Customizable solutions for research and production.

1400℃ Muffle Oven Furnace for Laboratory

KT-14M Muffle Furnace: Precision 1400°C heating with SiC elements, PID control, and energy-efficient design. Ideal for labs.

1200℃ Controlled Inert Nitrogen Atmosphere Furnace

KINTEK 1200℃ Controlled Atmosphere Furnace: Precision heating with gas control for labs. Ideal for sintering, annealing, and material research. Customizable sizes available.

1400℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-14A Controlled Atmosphere Furnace for labs & industry. 1400°C max temp, vacuum sealing, inert gas control. Customizable solutions available.

1700℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-17A Controlled Atmosphere Furnace: Precise 1700°C heating with vacuum & gas control. Ideal for sintering, research & material processing. Explore now!

Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

Discover KINTEK's Hydrogen Atmosphere Furnace for precise sintering & annealing in controlled environments. Up to 1600°C, safety features, customizable.

1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision heating up to 1700°C for material synthesis, CVD, and sintering. Compact, customizable, and vacuum-ready. Explore now!

Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

KinTek Vacuum Porcelain Furnace: Precision dental lab equipment for high-quality ceramic restorations. Advanced firing control & user-friendly operation.

1200℃ Muffle Oven Furnace for Laboratory

KINTEK KT-12M Muffle Furnace: Precision 1200°C heating with PID control. Ideal for labs needing rapid, uniform heat. Explore models & customization options.