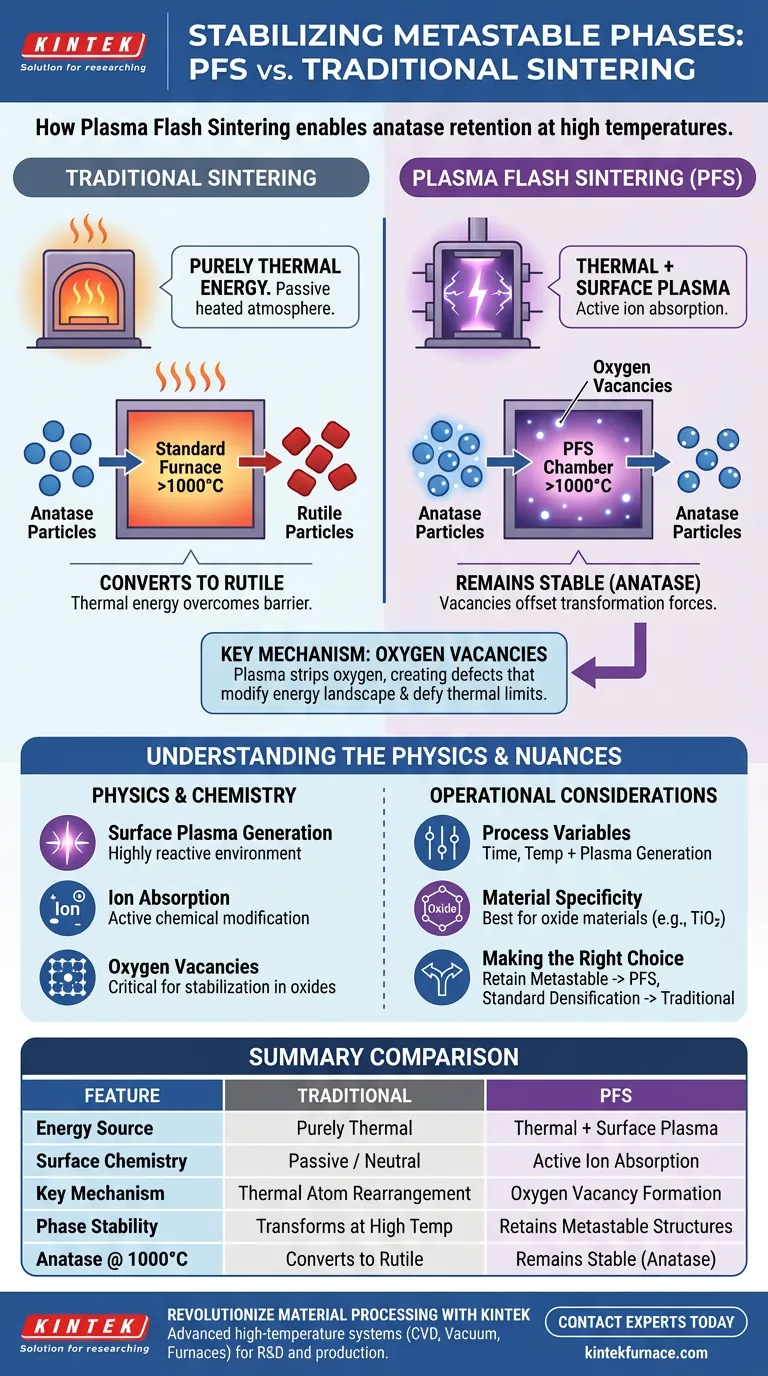

Plasma Flash Sintering (PFS) equipment stabilizes metastable phases by actively generating plasma on the material's surface, which induces specific chemical changes such as oxygen vacancies and the absorption of ionized species. This process fundamentally alters the thermodynamic environment, offsetting the natural driving forces that would normally cause a phase transformation at high temperatures. Consequently, materials like titanium dioxide can retain their metastable anatase phase even at temperatures exceeding 1000°C, a threshold where traditional equipment would force a complete conversion to rutile.

Core Takeaway: The stabilizing power of PFS lies in its ability to generate surface plasma that creates oxygen vacancies. These defects modify the material's energy landscape, allowing it to defy standard thermal limits and retain metastable structures at temperatures that usually force transformation.

The Physics of Stabilization

Surface Plasma Generation

Unlike traditional sintering which relies solely on thermal energy, PFS equipment generates plasma directly on the material surface.

This creates a highly energetic, reactive environment immediately surrounding the particles, rather than just a passive heated atmosphere.

Absorption of Ionized Species

The presence of plasma allows the material to absorb ionized species.

This interaction is not merely physical heating; it is an active chemical modification of the particle surface during the sintering process.

Altering Phase Thermodynamics

Creation of Oxygen Vacancies

The most critical mechanism identified in PFS is the formation of oxygen vacancies.

The plasma interaction strips oxygen from the lattice or rearranges the surface chemistry. These vacancies are not defects in the negative sense; they are the key to stabilization.

Offsetting Transformation Forces

Normally, high heat provides the energy required for atoms to rearrange into a more stable structure (e.g., Rutile).

However, the oxygen vacancies and absorbed ions induced by PFS offset these phase transformation driving forces. The chemical changes make the metastable phase energetically viable even when the thermal energy suggests it should transform.

PFS vs. Traditional Sintering

The Traditional Thermal Limit

In traditional sintering equipment, temperature is the primary variable.

When titanium dioxide is heated to 1000°C in a standard furnace, the thermal energy overcomes the energy barrier, causing the metastable anatase phase to fully transform into the stable rutile phase.

The PFS Advantage

PFS equipment breaks the link between temperature and inevitable phase transformation.

Because of the plasma-assisted effects, the anatase phase remains stable above 1000°C. This allows for high-temperature processing (which aids in densification) without losing the desired crystal structure.

Understanding the Operational Nuances

Complexity of Process Variables

While traditional sintering is largely controlled by time and temperature, PFS introduces plasma generation as a critical variable.

The stability of the phase is directly linked to the successful generation and maintenance of this plasma on the surface.

Material Specificity

The mechanism described relies heavily on defect chemistry, specifically oxygen vacancies.

This implies that the benefits of PFS are most pronounced in oxide materials (like titanium dioxide) where oxygen stoichiometry plays a role in phase stability.

Making the Right Choice for Your Goal

To determine if Plasma Flash Sintering is the correct solution for your application, consider your specific material requirements:

- If your primary focus is retaining metastable phases at high temperatures: Utilization of PFS is essential to leverage plasma-induced oxygen vacancies that counteract thermal transformation.

- If your primary focus is standard densification of stable phases: Traditional sintering methods may suffice, as the plasma-stabilization mechanism is unnecessary for materials where phase transformation is not a concern.

PFS transforms sintering from a purely thermal process into an electro-chemical one, offering a unique pathway to process temperature-sensitive crystal structures.

Summary Table:

| Feature | Traditional Sintering | Plasma Flash Sintering (PFS) |

|---|---|---|

| Energy Source | Purely Thermal | Thermal + Surface Plasma |

| Surface Chemistry | Passive / Neutral | Active Ion Absorption |

| Key Mechanism | Thermal Atom Rearrangement | Oxygen Vacancy Formation |

| Phase Stability | Transforms at High Temp | Retains Metastable Structures |

| Anatase @ 1000°C | Converts to Rutile | Remains Stable (Anatase) |

Revolutionize Your Advanced Material Processing with KINTEK

Don't let traditional thermal limits dictate your material's properties. KINTEK empowers researchers and manufacturers with cutting-edge high-temperature systems, including CVD, Vacuum, and customizable lab furnaces designed to handle complex sintering requirements. Whether you are aiming to stabilize metastable phases or achieve superior densification, our expert R&D team provides the precision tools necessary to push scientific boundaries.

Ready to elevate your material science? Contact our experts today to discuss how our specialized thermal solutions can meet your unique laboratory needs.

Visual Guide

References

- Eva Gil‐González, Luis A. Pérez‐Maqueda. Plasma‐flash sintering: Metastable phase stabilization and evidence of ionized species. DOI: 10.1111/jace.20105

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

People Also Ask

- How does a batch furnace differ from a continuous furnace? Choose the Right Furnace for Your Production Needs

- What is the primary function of a drying oven in the preparation of calcium oxide from eggshell waste? Maximize Purity

- What role do low-temperature carbonization furnaces play in carbon fiber manufacture? Build a Strong Structural Foundation

- What function does high-purity argon gas serve in BPEA PVT preparation? Ensure High-Quality Crystal Growth

- What are the advantages of HTL reactors for algae? Optimize Biomass Conversion Without Pre-Drying

- What is the function of an ultra-high vacuum sputtering system with multi-target for CuGaO2? Precision Synthesis Guide

- How does a dual-stage salt bath design address steel wire sorbitization? Master Precision Gradient Cooling

- Why is programmable heating equipment necessary for composite curing? Master Thermal Control for Superior Strength