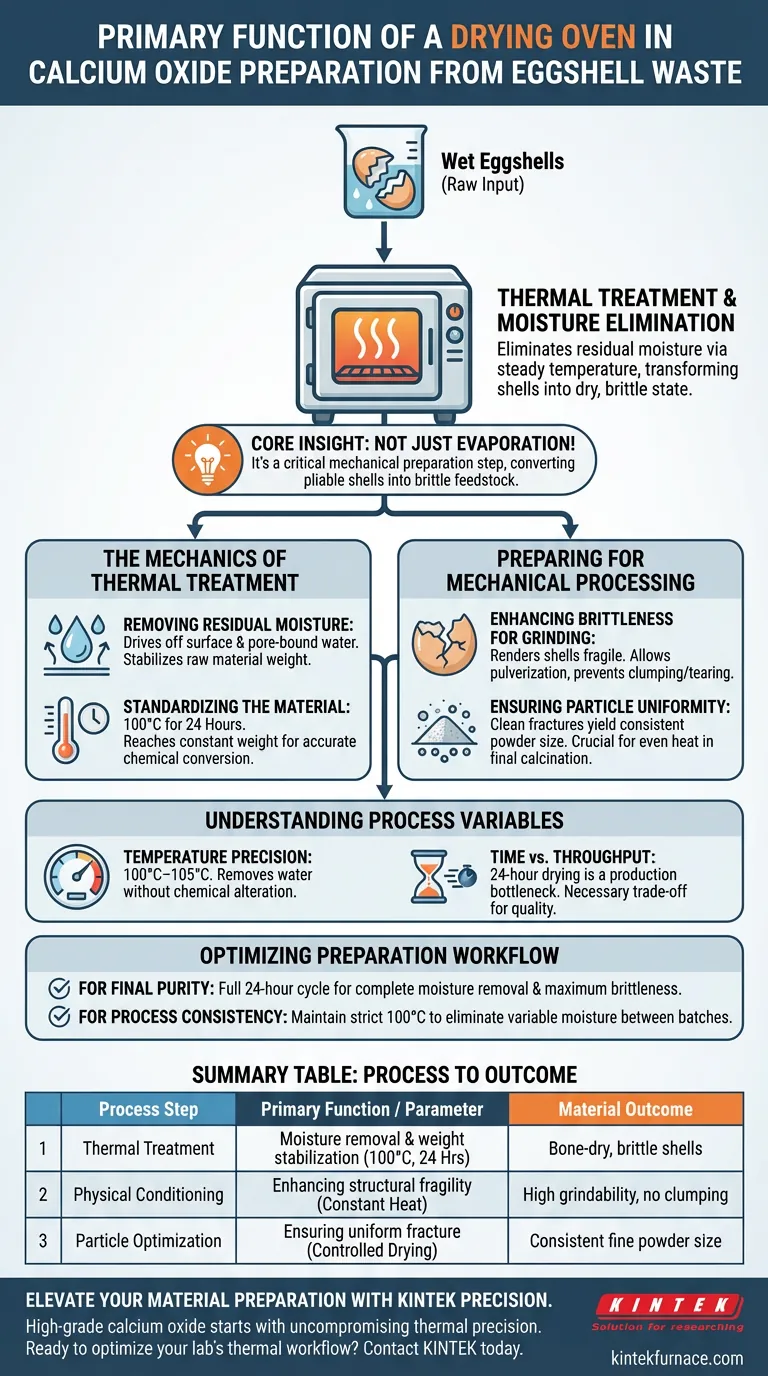

The primary function of a drying oven in this process is to eliminate residual moisture from cleaned eggshells via thermal treatment. By subjecting the waste material to a steady temperature (typically 100°C for 24 hours), the oven transforms the shells into a dry, brittle state. This physical conditioning is essential for successful mechanical grinding and ensures the uniformity of the final powder's particle size.

Core Insight: The drying phase is not merely about water evaporation; it is a critical mechanical preparation step. By removing moisture, you alter the structural integrity of the eggshell, converting it from a pliable organic-inorganic composite into a brittle feedstock capable of being ground into a consistent powder.

The Mechanics of Thermal Treatment

Removing Residual Moisture

After washing, eggshells retain significant surface and pore-bound water. The drying oven provides a consistent thermal environment to drive off this liquid.

This step stabilizes the raw material. By removing volatile moisture, you ensure the starting mass for subsequent steps is accurate, preventing discrepancies in chemical conversion later in the process.

Standardizing the Material

The standard protocol involves heating at approximately 100°C for 24 hours. This duration ensures the material reaches a "constant weight," meaning all free moisture has been evaporated.

Consistency here is vital. If moisture content varies between batches, the efficiency of the calcination process (turning calcium carbonate into calcium oxide) will fluctuate unpredictable.

Preparing for Mechanical Processing

Enhancing Brittleness for Grinding

Wet or damp eggshells possess a degree of elasticity due to residual membranes and water content. They tend to tear or clump rather than shatter.

Thermal treatment renders the shells brittle and fragile. This physical state is required for mechanical grinders to function effectively, allowing the shells to be pulverized rather than mashed.

Ensuring Particle Uniformity

The ultimate goal of the preparation phase is to create a fine powder. The drying process directly impacts the quality of this powder.

Thoroughly dried shells fracture cleanly, resulting in a uniform particle size. Uniform particles are crucial because they ensure even heat distribution during the final high-temperature calcination, leading to higher quality calcium oxide.

Understanding Process Variables and Trade-offs

Temperature Precision

While the goal is drying, precision is key. Operating around 100°C–105°C is the "sweet spot" for removing water without chemically altering the calcium carbonate structure prematurely.

Time vs. Throughput

The 24-hour drying cycle creates a significant bottleneck in production speed.

Attempting to shorten this time by increasing temperature can risk uneven drying or burning organic membranes, while reducing time may leave residual moisture that hampers grinding. This is a necessary trade-off for quality assurance.

Optimizing the Preparation Workflow

To ensure high-quality calcium oxide production, tailor your approach based on your specific requirements:

- If your primary focus is Final Purity: Ensure the drying cycle runs the full 24 hours to guarantee complete moisture removal and maximum brittleness for fine grinding.

- If your primary focus is Process Consistency: Utilize a drying oven capable of maintaining a strict 100°C constant temperature to eliminate variable moisture content between different batches.

Proper drying is the unglamorous but non-negotiable foundation of producing high-grade calcium oxide from waste.

Summary Table:

| Process Step | Primary Function | Typical Parameter | Material Outcome |

|---|---|---|---|

| Thermal Treatment | Moisture removal & weight stabilization | 100°C for 24 Hours | Bone-dry, brittle shells |

| Physical Conditioning | Enhancing structural fragility | Constant Heat | High grindability, no clumping |

| Particle Optimization | Ensuring uniform fracture | Controlled Drying | Consistent fine powder size |

Elevate Your Material Preparation with KINTEK Precision

High-grade calcium oxide starts with uncompromising thermal precision. Backed by expert R&D and manufacturing, KINTEK offers high-performance drying ovens, Muffle, Tube, Rotary, Vacuum, and CVD systems designed to deliver the consistent heat distribution your research demands. Whether you are repurposing waste or developing advanced ceramics, our customizable lab solutions ensure your feedstocks are perfectly conditioned for successful calcination.

Ready to optimize your lab's thermal workflow? Contact us today to find the perfect system for your unique needs.

Visual Guide

References

- Budi Prayitno, Siska Ayu Kartika. THE EFFECT OF CALCINATION TEMPERATURE AND HOLDING TIME ON STRUCTURAL PROPERTIES OF CALCIA POWDERS DERIVED FROM EGGSHELL WASTE. DOI: 10.29303/ipr.v8i1.450

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How do the rotational and orbital movements of the sample stage contribute to the uniformity of coatings on Zircaloy?

- Why is vacuum sealing technology essential for K2In2As3 synthesis? Master High-Purity Solid-State Reactions

- What is the purpose of performing a 600 degree Celsius annealing treatment? Enhance AZO Thin Film Stability

- Why is vacuum degassing necessary for ZIF-8 impregnation? Achieve Uniform Macroporous Material Synthesis

- How does a high-precision laboratory oven ensure the performance of large-scale halide perovskite catalyst plates?

- What is the function of solution and aging heat treatment furnaces? Optimize 17-4 PH Stainless Steel Properties

- Why is high temperature control stability required for KAS method kinetics? Ensure Accurate Activation Energy Results

- What process conditions are provided by the molten NaOH-KOH system? High-Temp Salt Etching for Silicon Recovery