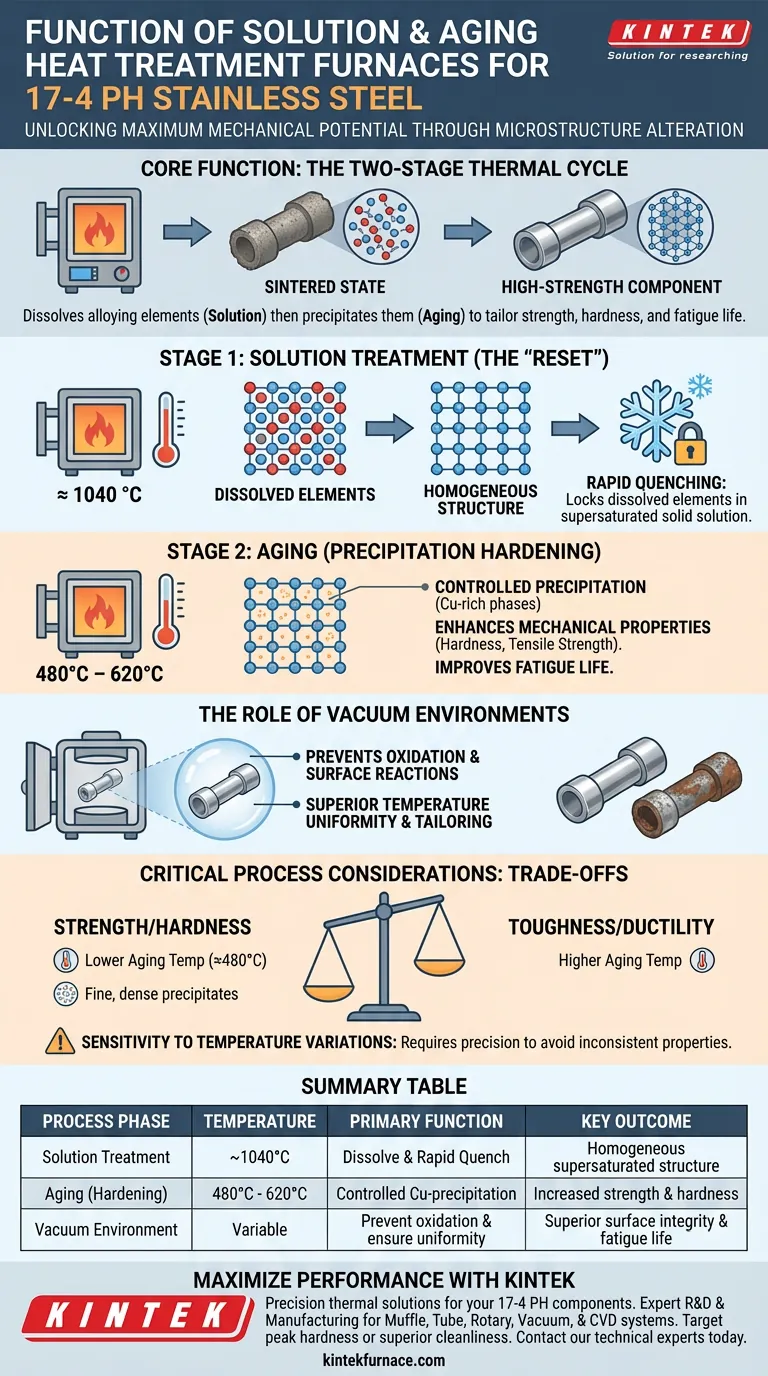

The primary function of solution and aging heat treatment furnaces is to fundamentally alter the microstructure of 17-4 PH stainless steel to unlock its maximum mechanical potential. These furnaces execute a precise two-stage thermal cycle that dissolves alloying elements and then precipitates them in a controlled manner, transforming parts from a standard sintered state into high-strength, durable components.

Core Takeaway Solution and aging furnaces are not merely for finishing; they are critical for property activation. By dissolving alloying elements at high temperatures and precipitating intermetallic compounds at lower temperatures, this equipment provides the necessary control to tailor strength, hardness, and fatigue life for demanding applications.

The Solution Treatment Phase

This initial stage prepares the metal’s atomic structure for strengthening. It acts as a "reset" button for the material's microstructure.

Dissolving Alloying Elements

The furnace heats the 17-4 PH parts to approximately 1040 °C. At this specific temperature, the heat allows the alloying elements to fully dissolve into the iron matrix.

Creating a Homogeneous Structure

This process eliminates segregation within the material. It ensures a uniform distribution of elements, which is essential for consistent performance across the entire part.

Rapid Quenching

Following the high-heat soak, the furnace facilitates rapid quenching. This sudden cooling "locks" the dissolved elements in place, creating a supersaturated solid solution that is ready for the strengthening phase.

The Aging (Precipitation Hardening) Phase

Once the structure is locked, the aging furnace carefully reheats the metal to activate its strength.

Controlled Precipitation

During aging, the furnace holds the parts at temperatures typically between 480°C and 620°C. This induces the precipitation of nano-sized copper-rich (Cu-rich) phases dispersed throughout the material.

Enhancing Mechanical Properties

This dispersion of intermetallic compounds impedes dislocation movement within the crystal lattice. The result is a significant increase in hardness and tensile strength compared to the as-sintered state.

Improving Fatigue Life

Beyond static strength, this precise thermal cycling improves the component's resistance to cyclic loading. This dramatically extends the fatigue life of Metal Injection Molding (MIM) parts.

The Role of Vacuum Environments

Modern aging furnaces, particularly vacuum brazing types, utilize controlled atmospheres to ensure quality.

Superior Temperature Uniformity

Vacuum furnaces offer precise programmable cooling rates and heat distribution. This allows for the exact tailoring of precipitate size and distribution density.

Preventing Surface Reactions

The vacuum environment prevents the material from reacting with environmental impurities. This eliminates oxidation and ensures sample cleanliness, which is critical for the reliability of subsequent electrochemical testing or surface finishing.

Critical Process Considerations

While these furnaces offer immense control, the process involves inherent trade-offs that must be managed.

The Trade-off Between Strength and Ductility

The aging temperature acts as a dial between hardness and toughness. Lower aging temperatures generally yield higher strength but reduced ductility, while higher temperatures increase toughness at the expense of peak hardness.

Sensitivity to Temperature Variations

17-4 PH is highly sensitive to thermal fluctuations during aging. Even minor deviations in furnace uniformity can lead to inconsistent precipitation, resulting in parts that fail to meet strict aerospace or medical specifications.

Making the Right Choice for Your Goal

To maximize the utility of your heat treatment strategy, align your furnace parameters with your specific performance requirements.

- If your primary focus is Maximum Strength and Hardness: Target the lower end of the aging temperature range (near 480°C) to generate fine, dense precipitates.

- If your primary focus is Surface Integrity and Cleanliness: Utilize a vacuum furnace environment to prevent oxidation and ensure the chemical purity of the surface for sensitive applications.

The effectiveness of 17-4 PH stainless steel relies entirely on the precision of the thermal cycle; the furnace is the tool that turns potential chemistry into actual performance.

Summary Table:

| Process Phase | Temperature Range | Primary Function | Key Outcome |

|---|---|---|---|

| Solution Treatment | ~1040°C | Dissolve alloying elements & rapid quench | Homogeneous supersaturated structure |

| Aging (Hardening) | 480°C - 620°C | Controlled precipitation of Cu-rich phases | Increased tensile strength & hardness |

| Vacuum Environment | Variable | Prevents oxidation & ensures uniformity | Superior surface integrity & fatigue life |

Maximize Your Material Performance with KINTEK

Unlock the full potential of your 17-4 PH stainless steel components with KINTEK’s precision thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique metallurgical requirements.

Whether you are targeting peak hardness for aerospace parts or superior surface cleanliness for medical devices, our advanced furnaces provide the temperature uniformity and atmospheric control necessary for critical heat treatments. Contact our technical experts today to find the ideal furnace for your lab or production line.

Visual Guide

References

- Jorge Luis Braz Medeiros, Luciano Volcanoglo Biehl. Effect of Sintering Atmosphere Control on the Surface Engineering of Catamold Steels Produced by MIM: A Review. DOI: 10.3390/surfaces9010007

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does the temperature capability of continuous furnaces benefit industrial processes? Boost High-Volume Production with Extreme Heat

- What is the effect of 750°C to 950°C on activated carbon? Optimize Pore Structure & Surface Area

- What is graphite furnace atomic absorption spectroscopy used for? Detecting Trace Elements at Parts-Per-Billion Levels

- How does a PID intelligent segmented temperature control system impact diamond tools? Precision Sintering Explained

- Why must ultra-high purity argon be continuously supplied for Aluminum-Silicon alloys? Ensure Viscosity Data Accuracy

- What are the benefits of ESR for carbonitride distribution in H13 steel? Enhance Your Material's Isotropic Properties

- Why is dual heat treatment required for SnO2 nanoparticles? Optimize Oxidation for Superior Performance

- What is the primary purpose of a high-temperature furnace in ammonia decomposition? Maximizing Thermal Activation