Electroslag Remelting (ESR) fundamentally refines the internal structure of H13 steel to optimize its mechanical performance. By controlling the cooling process, ESR specifically inhibits the coarsening of large primary carbonitrides and significantly reduces elemental segregation. This results in a material with superior isotropic properties, meaning it possesses uniform strength and toughness in all directions.

The core value of Electroslag Remelting lies in its ability to suppress the growth of large, detrimental carbonitride particles through precise cooling rates. This creates a cleaner, more homogeneous microstructure that is essential for high-performance applications.

The Mechanics of Microstructural Refinement

To understand why ESR improves carbonitride distribution, one must look at how the steel is processed.

The Secondary Refining Process

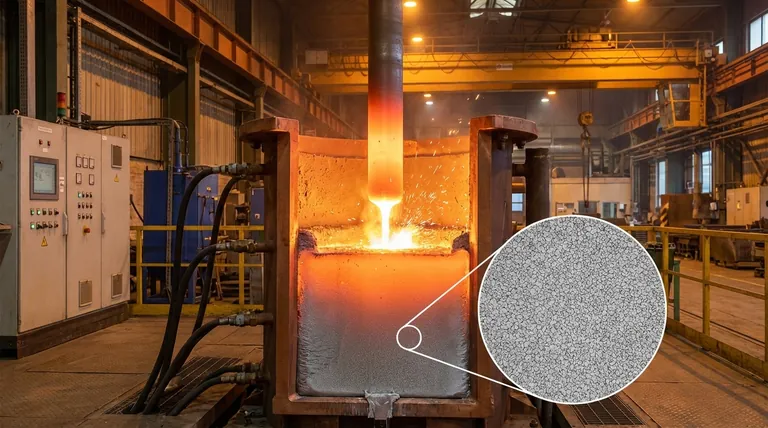

ESR is defined as a secondary refining process. A consumable electrode made of the base steel is melted by the resistance heat generated within a conductive slag pool.

Purification via Slag

As the metal melts, droplets pass through this slag layer. This transit filters the steel, further purifying the metal droplets before they solidify.

Controlled Solidification

The process utilizes a specialized mold with specific cooling characteristics. This controlled environment is the critical factor that dictates the final arrangement of the steel's internal components.

Impact on Carbonitrides and Segregation

The specific cooling provided by ESR directly addresses the common defects found in standard H13 steel production.

Inhibiting Particle Growth

Standard casting can allow carbonitrides to grow into large, brittle clusters. ESR inhibits the coarsening of large primary carbonitrides, keeping these particles small and well-distributed.

Reducing Elemental Segregation

In many steel manufacturing processes, chemical elements tend to separate or "segregate" during cooling. ESR significantly reduces this elemental segregation, ensuring a consistent chemical composition throughout the ingot.

Achieving Isotropic Properties

The combination of fine carbonitride distribution and reduced segregation improves the isotropic properties of H13 steel. This ensures the material behaves predictably regardless of the direction of stress or load.

Understanding the Process Implications

While the benefits are significant, it is important to recognize the nature of the process.

Additional Processing Requirements

ESR is a secondary step, meaning it occurs after the initial creation of the steel electrode. It requires specialized equipment to maintain the slag pool and manage the resistance heat necessary for remelting.

Dependence on Cooling Rates

The success of the carbonitride distribution relies heavily on the specific cooling characteristics of the mold. Deviations in this cooling profile could compromise the inhibition of particle coarsening.

Making the Right Choice for Your Goal

When selecting materials for critical applications, understanding the influence of ESR on H13 steel allows for better decision-making.

- If your primary focus is durability and toughness: Prioritize ESR-processed H13 to ensure large primary carbonitrides are minimized, reducing potential fracture points.

- If your primary focus is multi-directional strength: Select ESR steel to leverage its improved isotropic properties derived from reduced elemental segregation.

By utilizing Electroslag Remelting, you ensure the H13 steel achieves the microstructural uniformity required for high-stress environments.

Summary Table:

| Feature | Impact of ESR Process on H13 Steel |

|---|---|

| Carbonitride Growth | Inhibits coarsening of large primary particles |

| Elemental Distribution | Significantly reduces chemical segregation |

| Internal Structure | Achieves a cleaner, more homogeneous microstructure |

| Mechanical Quality | Provides superior isotropic (multi-directional) properties |

| Purification Method | Filtration of metal droplets through a conductive slag pool |

Elevate Your Material Performance with KINTEK

Are you looking to optimize the microstructural integrity of your high-performance alloys? Backed by expert R&D and manufacturing, KINTEK offers specialized thermal solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique material processing needs.

Whether you are refining H13 steel or developing advanced ceramics, our precision lab high-temp furnaces ensure the controlled solidification and heating environments necessary for superior isotropic properties. Don't settle for inconsistent results.

Contact KINTEK today to discuss your custom furnace requirements and see how our expert technology can bring precision to your laboratory or production line.

References

- Xiaolin Sun, Shuo Zhao. Effects of Ti and N Contents on the Characteristic Evolution and Thermal Stability of MC Carbonitrides Holding at 1250 °C in H13 Die Steel. DOI: 10.3390/met14030317

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a forced-air drying oven necessary for impregnated kaolin catalysts? Achieve Uniform Component Immobilization

- What role does pack media play in the solid-state powder boriding process? Enhance Metal Hardness at High Temperatures

- Why must Ru/GNK catalysts undergo vacuum drying? Ensure Peak Performance with Safe Desorption

- Why are graphite molds preheated to 800 °C for Invar 36 casting? Unlock High-Quality Ingot Production

- What is the importance of a laboratory oven's programmed heating for epoxy-polyimide curing? Essential Thermal Control

- Why is film uniformity important in semiconductor manufacturing? Ensure High Device Performance and Yield

- What are the advantages of using the foil-fiber-foil method for SiC/TB8 plates? Efficient SiC/TB8 Composite Production

- What additional benefits do vacuum chambers provide beyond environmental control? Enhance Material Purity and Process Efficiency