Preheating high-performance graphite molds to 800 °C is a strategic thermal management technique used to drastically reduce the cooling rate of molten Invar 36 alloy. This specific temperature threshold is critical for preventing rapid solidification, which is the primary cause of structural defects in the finished metal.

By significantly slowing the cooling process, preheating prevents the formation of internal casting voids. This ensures the production of high-quality ingots that maintain their structural integrity during subsequent thermal processing.

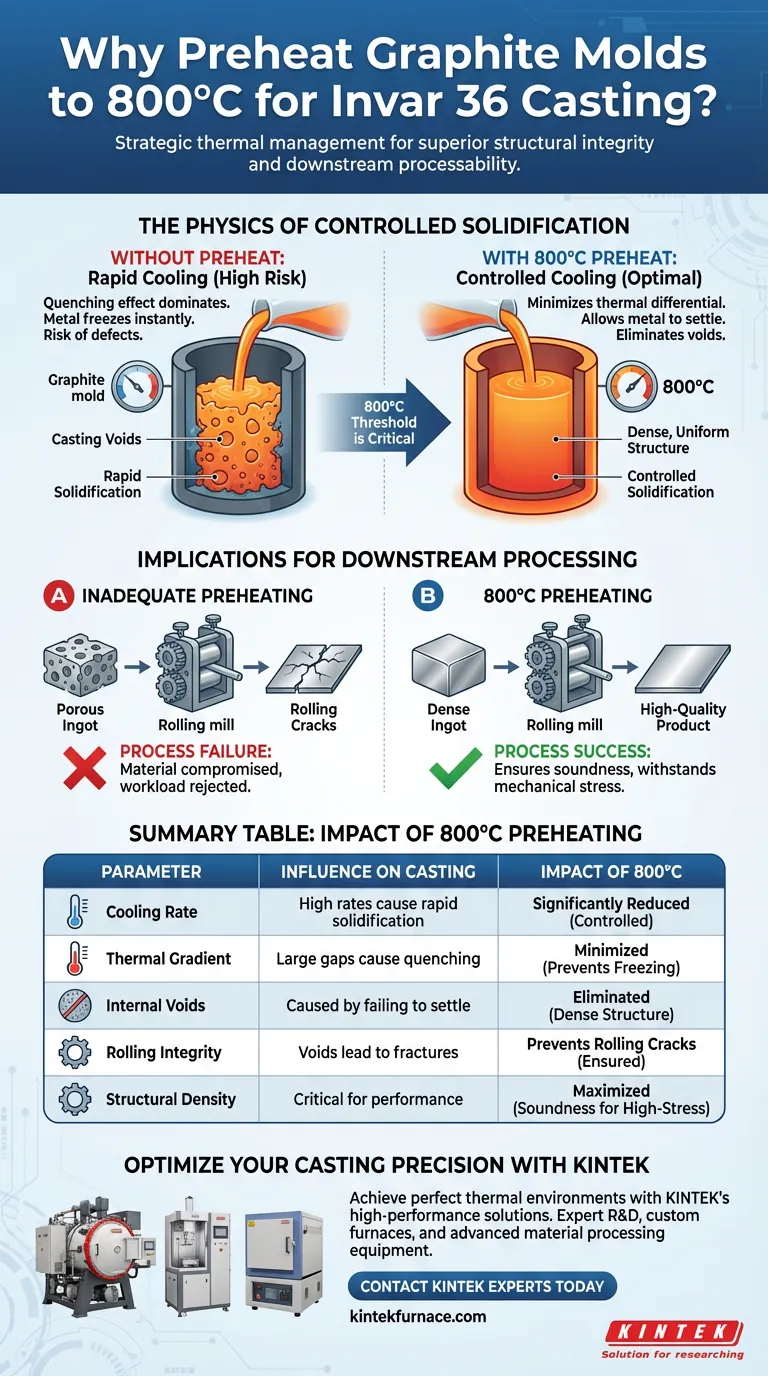

The Physics of Controlled Solidification

To understand why 800 °C is the target temperature, one must look at the behavior of the molten alloy as it enters the mold.

Mitigating the Quenching Effect

When molten metal comes into contact with a mold significantly cooler than itself, it undergoes a "quenching effect." This causes the metal to freeze almost instantly upon contact.

By preheating the graphite mold to 800 °C, manufacturers minimize the temperature differential between the mold and the melt. This ensures the metal remains in a liquid state longer, allowing for a controlled, gradual solidification process.

Eliminating Casting Voids

The primary danger of rapid solidification is the formation of casting voids. These are internal cavities or gaps that occur when the metal solidifies too quickly to settle properly.

Slowing the cooling rate allows the molten Invar 36 to settle and fill the mold volume completely before hardening. This directly counters the creation of voids, resulting in a dense, uniform ingot.

Implications for Downstream Processing

The benefits of preheating extend beyond the casting phase; they are essential for the viability of the metal in later manufacturing stages.

Preventing Rolling Cracks

Invar 36 ingots typically undergo rolling—a thermal process used to flatten or shape the metal—after casting. If the ingot contains casting voids, the stress of rolling will cause the material to fracture.

These fractures, known as rolling cracks, compromise the entire workload. By preventing voids during the initial cast via preheating, manufacturers significantly reduce the likelihood of these cracks appearing during rolling.

Ensuring High-Quality Ingots

The ultimate goal of this thermal preparation is the production of a "high-quality" ingot. In this context, quality is defined by internal soundness and the ability to withstand mechanical stress.

Without the 800 °C preheat, the ingot would likely be rejected due to internal defects or fail during subsequent processing steps.

Common Pitfalls: The Risks of Inadequate Preheating

While preheating adds time and energy to the process, failing to reach the requisite 800 °C introduces severe risks to the material's integrity.

The Danger of Rapid Cooling

If the mold temperature is too low, the cooling rate accelerates. This reverts the process to a state where the quenching effect dominates, reintroducing the risk of cold shuts (where metal streams fail to fuse) or incomplete mold filling.

Compromised Structural Density

Insufficient preheating leads to an ingot with a compromised internal structure. Even if the surface appears sound, internal voids created by rapid cooling will act as stress concentrators, leading to inevitable failure when the material is worked mechanically.

Making the Right Choice for Your Goal

To apply this to your specific manufacturing context, consider your primary objectives regarding material integrity and processing.

- If your primary focus is Internal Soundness: Ensure the mold reaches the full 800 °C to maximize the settling time of the melt and eliminate casting voids.

- If your primary focus is Downstream Processability: Prioritize the preheat cycle to protect against rolling cracks, which are direct consequences of initial casting defects.

Mastering the preheat temperature is not just a casting step; it is the foundational assurance of the alloy's future performance.

Summary Table:

| Parameter | Influence on Invar 36 Casting | Impact of 800 °C Preheating |

|---|---|---|

| Cooling Rate | High rates cause rapid solidification | Significantly reduced; allows controlled cooling |

| Thermal Gradient | Large gaps cause quenching effects | Minimized; prevents immediate metal freezing |

| Internal Voids | Caused by metal failing to settle | Eliminated; ensures dense, uniform ingot structure |

| Rolling Integrity | Voids lead to fractures during shaping | Prevents rolling cracks during downstream processing |

| Structural Density | Critical for mechanical performance | Maximized; ensures soundness for high-stress applications |

Optimize Your Casting Precision with KINTEK

Achieving the perfect 800 °C thermal environment requires precision equipment that stands up to rigorous industrial demands. KINTEK provides industry-leading high-temperature furnaces, vacuum systems, and CVD solutions specifically designed for advanced material processing.

Whether you are casting Invar 36 or developing specialized alloys, our expert R&D team offers customizable lab and industrial furnaces to ensure your molds reach exact temperature thresholds every time. Prevent defects and maximize your production yield today.

Ready to elevate your thermal processing?

Visual Guide

References

- Mehmet Kul, Markus Merkel. Minimum and Stable Coefficient of Thermal Expansion by Three-Step Heat Treatment of Invar 36. DOI: 10.3390/cryst14121097

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary function of adding bentonite and cement as binders? Optimize Iron Ore Briquette Strength

- What type of furnace was chosen for annealing silicon-based materials and what were the key requirements? Discover the Ideal Solution for Precise Heat Treatment

- How does controlled thermal treatment affect delta-MnO2? Optimize Porosity & Surface Area for Better Battery Performance

- Why is aluminum foil used during selenization and carbonization? Unlock Superior ZnSe Nanoparticle Synthesis

- What role does active carbon play in CaS:Eu2+ phosphor synthesis? Key to Activating High-Efficiency Luminescence

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a high vacuum drying oven in B4C/Al powder pretreatment? Protect Purity & Prevent Pores

- What role does a laboratory oven play in the drying phase of Co–Mg catalyst precursors? Ensuring Component Uniformity