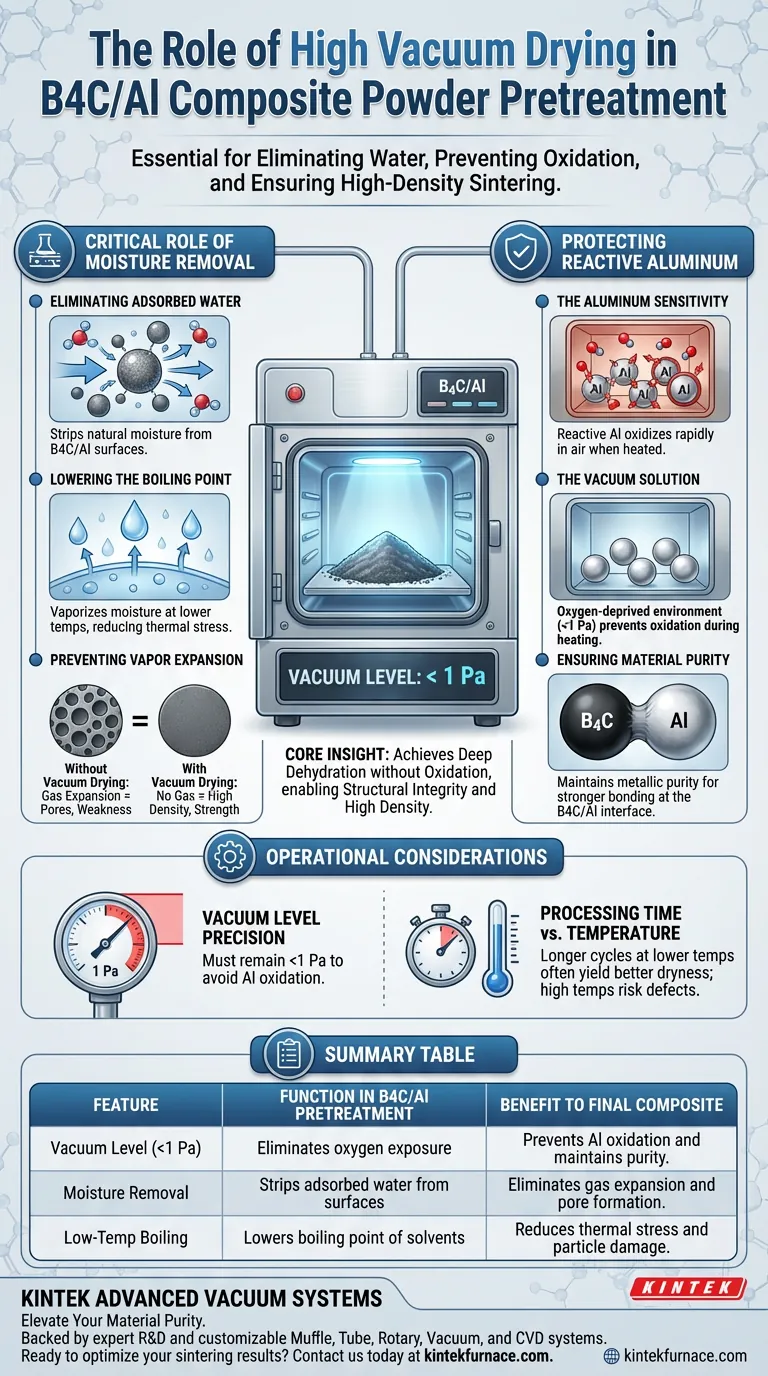

The primary function of a high vacuum drying oven in the pretreatment of B4C/Al (Boron Carbide/Aluminum) composite powders is to thoroughly eliminate adsorbed water while preventing the oxidation of the aluminum component. By maintaining a vacuum environment below 1 Pa, the oven ensures the raw materials remain chemically pure, creating the necessary conditions for successful high-density sintering.

Core Insight High vacuum drying resolves a critical conflict in material processing: it allows for deep dehydration of reactive powders without exposing them to the oxygen found in standard thermal drying. This step is the "gatekeeper" for structural integrity, as residual moisture or surface oxides will inevitably lead to pores and structural failure during the subsequent densification phase.

The Critical Role of Moisture Removal

Eliminating Adsorbed Water

The surface of Boron Carbide and Aluminum powders naturally attracts and holds moisture (adsorbed water) from the ambient environment. The high vacuum drying oven is specifically engineered to strip this water away from the particle surfaces.

Lowering the Boiling Point

By creating a low-pressure environment, the vacuum oven significantly lowers the boiling point of water and other residual solvents. This allows moisture to vaporize and escape at lower temperatures, reducing the thermal stress on the material.

Preventing Vapor Expansion

If this moisture is not removed prior to the next processing stage, it will vaporize rapidly during high-temperature sintering. This gas expansion within the material matrix creates pores, which destroys the density and mechanical strength of the final composite.

Protecting Reactive Aluminum

The Aluminum Sensitivity

Aluminum powder is highly reactive and prone to rapid oxidation when heated in the presence of air. A standard drying oven would remove the water but simultaneously degrade the aluminum by forming a thick oxide layer on the particles.

The Vacuum Solution

Operating at a vacuum level below 1 Pa creates an oxygen-deprived environment. This allows the system to apply the heat necessary for drying without triggering the chemical reaction that oxidizes aluminum.

Ensuring Material Purity

Preserving the metallic purity of the aluminum is essential for the interface between the metal matrix and the ceramic reinforcement. High purity ensures better bonding during the sintering process, leading to a stronger final composite.

Operational Considerations and Trade-offs

Vacuum Level Precision

Achieving the specific threshold of below 1 Pa is not optional for this specific composite. If the vacuum pressure rises above this limit, the partial pressure of oxygen may become sufficient to initiate oxidation in the aluminum powder, negating the benefit of the process.

Processing Time vs. Temperature

While vacuum drying allows for lower temperatures, it often requires longer cycle times to achieve the same level of dryness compared to atmospheric heating. Attempting to rush this process by aggressively raising the temperature—even under vacuum—can risk particle agglomeration or other thermal defects.

Making the Right Choice for Your Goal

To ensure the success of your B4C/Al composite fabrication, consider your specific processing objectives:

- If your primary focus is Maximum Density: Prioritize achieving the deepest possible vacuum (<1 Pa) to ensure zero moisture remains to form pores during sintering.

- If your primary focus is Material Purity: strictly monitor the vacuum seal integrity to ensure no oxygen leakage occurs during the heating cycle, protecting the aluminum surface.

This pretreatment is not merely a cleaning step; it is the fundamental control point that determines whether your B4C/Al composite will achieve its theoretical strength.

Summary Table:

| Feature | Function in B4C/Al Pretreatment | Benefit to Final Composite |

|---|---|---|

| Vacuum Level (<1 Pa) | Eliminates oxygen exposure | Prevents Al oxidation and maintains purity |

| Moisture Removal | Strips adsorbed water from surfaces | Eliminates gas expansion and pore formation |

| Low-Temp Boiling | Lowers boiling point of solvents | Reduces thermal stress and particle damage |

| Pure Environment | Maintains metallic interface | Ensures strong bonding between ceramic and metal |

Elevate Your Material Purity with KINTEK Advanced Vacuum Systems

Precise pretreatment is the difference between structural failure and high-performance composites. At KINTEK, we understand that B4C/Al processing requires rigorous vacuum precision and thermal control.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temp furnaces are fully customizable to meet your unique research or production needs, ensuring your powders stay oxygen-free and perfectly dry.

Ready to optimize your sintering results? Contact us today to discuss your custom furnace requirements with our technical team!

Visual Guide

References

- Chunfa Huang, Qiulin Li. Synergistic Optimization of High-Temperature Mechanical Properties and Thermal Conductivity in B4C/Al Composites Through Nano-Al2O3 Phase Transformation and Process Engineering. DOI: 10.3390/met15080874

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the function of a laboratory vacuum drying oven in alpha-K3[CuIO6]·4H2O synthesis? Protect Crystal Integrity

- What is the function of an industrial drying oven in ZnZrOx catalyst prep? Ensure Uniform Metal Precursor Adsorption

- What are the advantages of supersonic inert gas cooling in DGCC? Transform Heat Treatment and Microstructure Control

- What type of reaction environment is required for the synthesis of Ge-Se-Tl-Sb chalcogenide glasses? | KINTEK

- What role does a precision mass loss measurement system play? Identifying Vapor Pressure in High-Temp Furnaces

- What is the significance of using a 650°C annealing furnace for 42CrMo/Cr5 composite rollers after forging?

- What is the function of ball milling in Li-NASICON synthesis? Optimize Your Solid Electrolyte Performance

- Why is an industrial constant temperature oven required to cure thermal pads? Ensure Superior Polymer Cross-Linking