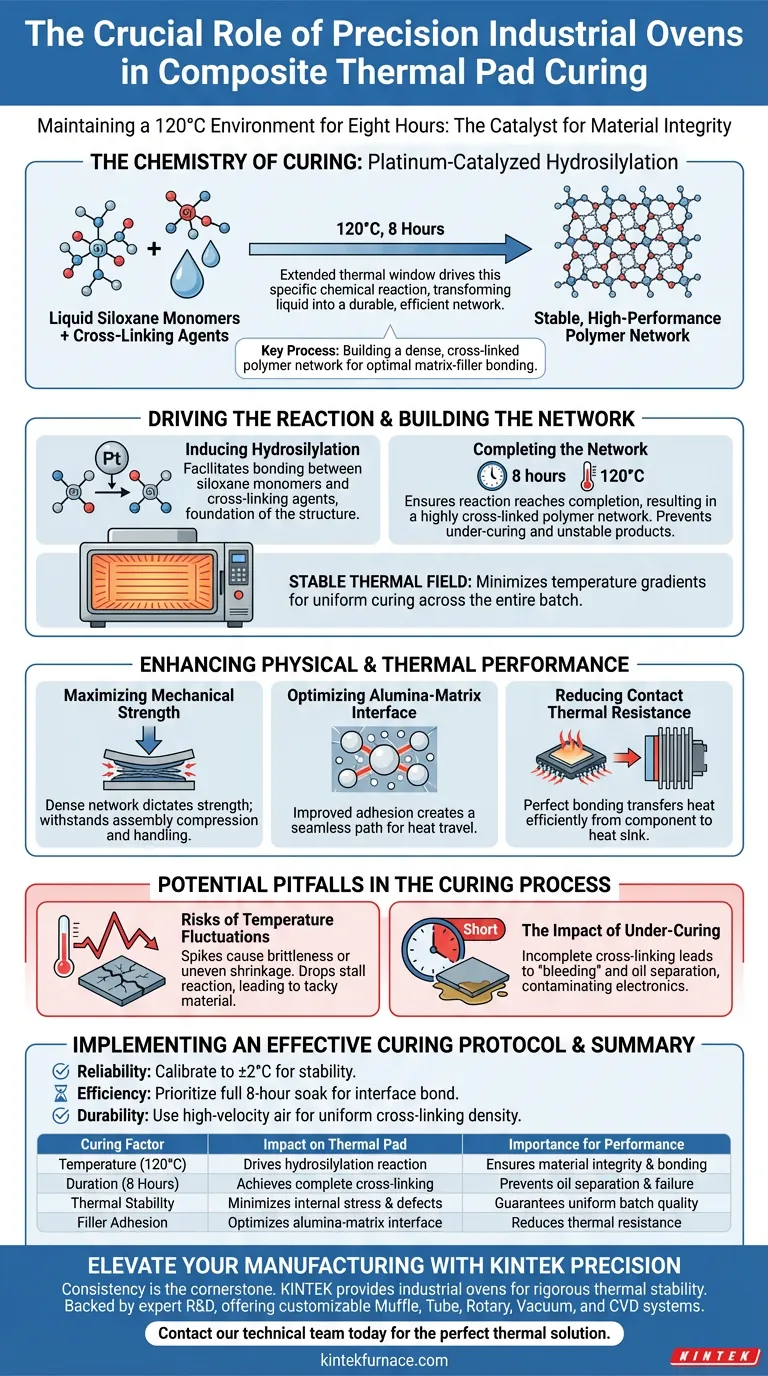

Precise temperature control is the catalyst for material integrity. To effectively cure composite thermal pads, an industrial oven must maintain 120°C for eight hours to drive a specific chemical reaction known as platinum-catalyzed hydrosilylation. This extended thermal window transforms liquid siloxane monomers into a stable, high-performance polymer network that provides both structural durability and efficient heat transfer.

The eight-hour curing cycle at 120°C is a controlled chemical process designed to build a dense, cross-linked polymer network. This precise thermal treatment optimizes the bond between the matrix and thermal fillers, ensuring the finished pad meets rigorous mechanical and thermal conductivity standards.

The Chemistry of Curing

Driving the Hydrosilylation Reaction

The primary purpose of the constant temperature is to induce the platinum-catalyzed hydrosilylation reaction. This chemical process facilitates the bonding between siloxane monomers and cross-linking agents, which is the foundation of the thermal pad's structure.

Building the Cross-Linked Network

Maintaining 120°C for a full eight hours ensures that the reaction reaches completion, resulting in a highly cross-linked polymer network. Without this specific duration, the material may remain "under-cured," leading to a soft or unstable product that fails in the field.

Ensuring a Stable Thermal Field

Industrial ovens are required because they provide a stable thermal field that minimizes temperature gradients. Uniform heat distribution is essential to ensure that the entire batch of thermal pads cures at the same rate, preventing internal stresses or localized defects.

Enhancing Physical and Thermal Performance

Maximizing Mechanical Strength

The density of the cross-linked network directly dictates the mechanical strength of the final thermal pad. A fully cured network allows the pad to withstand compression and handling during the assembly of electronic components without tearing or losing its shape.

Optimizing the Alumina-Matrix Interface

Thermal pads often contain alumina particles to enhance conductivity. The eight-hour cure improves the adhesion between these particles and the siloxane matrix, creating a seamless path for heat to travel through the material.

Reducing Contact Thermal Resistance

Improved interface adhesion has a direct impact on performance by reducing contact thermal resistance. When the matrix and the alumina particles are perfectly bonded, the pad can transfer heat from a component to a heat sink more efficiently.

Potential Pitfalls in the Curing Process

Risks of Temperature Fluctuations

If the temperature drops below 120°C, the hydrosilylation reaction may stall, resulting in a tacky or weak material. Conversely, spikes in temperature can cause the polymer to become brittle or lead to uneven shrinkage, which compromises the pad's flat profile.

The Impact of Under-Curing

Shortening the eight-hour window is a common mistake that leads to incomplete cross-linking. This often results in "leeding" or oil separation over time, which can contaminate sensitive electronic circuitry and lead to premature component failure.

Implementing an Effective Curing Protocol

Guidelines for Success

To ensure your thermal pads meet the necessary performance specifications, the curing process must be treated as a critical manufacturing step rather than a secondary task.

- If your primary focus is long-term reliability: Ensure the oven is calibrated to maintain ±2°C accuracy to guarantee the stability of the polymer network.

- If your primary focus is thermal efficiency: Prioritize the full eight-hour soak to maximize the interface bond between the alumina fillers and the matrix.

- If your primary focus is mechanical durability: Verify that the cross-linking density is uniform across the entire batch by using an oven with high-velocity air circulation.

Consistency in the thermal environment is the only way to guarantee that a composite thermal pad will perform reliably in high-stress electronic applications.

Summary Table:

| Curing Factor | Impact on Thermal Pad | Importance for Performance |

|---|---|---|

| Temperature (120°C) | Drives platinum-catalyzed hydrosilylation | Ensures material integrity and chemical bonding |

| Duration (8 Hours) | Achieves complete cross-linking density | Prevents oil separation and mechanical failure |

| Thermal Stability | Minimizes internal stress and defects | Guarantees uniform batch quality and conductivity |

| Filler Adhesion | Optimizes alumina-matrix interface | Reduces thermal resistance for better heat transfer |

Elevate Your Manufacturing with KINTEK Precision

Consistency is the cornerstone of high-performance composite curing. KINTEK provides industry-leading industrial ovens designed to maintain the rigorous thermal stability required for eight-hour curing cycles.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized lab high-temperature furnaces—all fully customizable to your specific heating profiles and material needs.

Don't let temperature fluctuations compromise your product's reliability. Contact our technical team today to find the perfect thermal solution for your laboratory or production line.

Visual Guide

References

- Seul-Ki Kim, Eun Young Jung. Fabrication and Characterization of Al2O3-Siloxane Composite Thermal Pads for Thermal Interface Materials. DOI: 10.3390/ma17040914

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is the significance of using an Annealing Furnace in gas sensors? Enhance Stability and Sensitivity

- How does the analysis of optimized process paths assist in lab equipment selection? Expert Guide for Research Success

- What is the importance of the feeding system and ore distributing device? Unlock Peak Oil Shale Retorting Efficiency

- What are some examples of low-temperature industrial heating processes? Boost Efficiency and Sustainability

- What is the purpose of the sulfidation treatment process? Enhance Reactor Performance with DMDS Passivation

- What are the advantages of combining vacuum hot rolling with small hole vacuuming? High-Bonding Clad Plate Production

- Why is a stainless steel high-pressure autoclave essential for starch hydrogenation? Unlock Peak Reaction Efficiency

- What processes can continuous furnaces perform in a single step? Master Debinding and Sintering for High-Volume Production