In a single, uninterrupted operation, a continuous furnace is expertly designed to combine multiple thermal processes, most notably debinding and sintering. This integration is fundamental to high-volume manufacturing methods like Metal Injection Molding (MIM) and additive manufacturing, where a "green" part must have its binding agent removed before being fused into its final, dense metallic form.

The true value of a continuous furnace isn't just performing multiple steps at once; it's about transforming a series of discrete, variable batch jobs into a single, highly repeatable, and cost-effective industrial flow. This shift prioritizes consistency and throughput above all else.

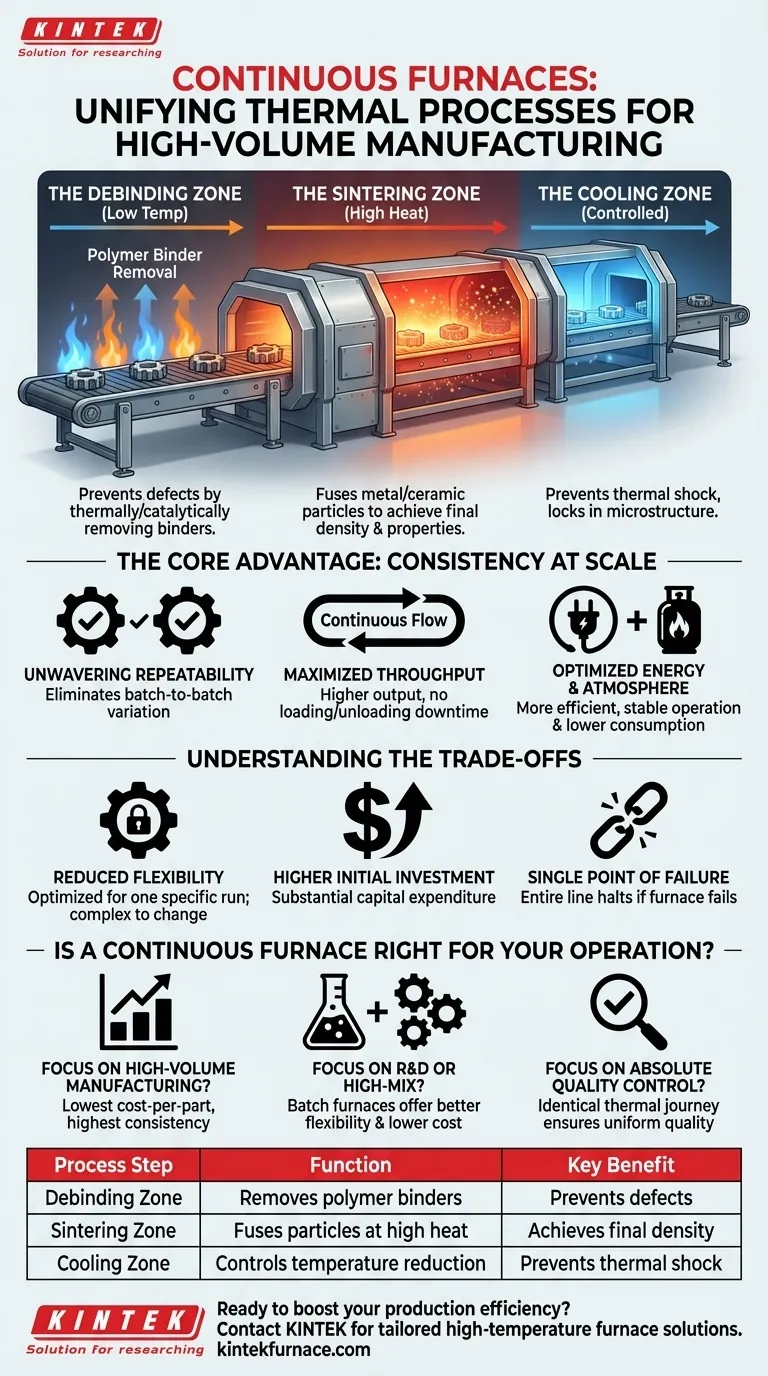

How Continuous Furnaces Integrate Processes

A continuous furnace isn't a single hot box. It's a long tunnel engineered with distinct thermal zones, each optimized for a specific stage of the manufacturing process. Parts move through these zones on a conveyor belt or pusher system, ensuring every single component experiences the exact same temperature profile.

The Debinding Zone

The first stage a part enters is the debinding zone. Here, at relatively low temperatures, the furnace's atmosphere is carefully controlled to thermally or catalytically decompose and remove the polymer binders that give the "green" part its initial shape. This step is critical for preventing defects in the final product.

The Sintering Zone

After the binders are removed, the parts move into the high-heat sintering zone. The temperature is ramped up significantly, often close to the material's melting point. In this zone, the metal or ceramic particles fuse together, eliminating voids and densifying the part to achieve its final mechanical properties.

The Cooling Zone

The final, and equally critical, stage is a controlled cooling zone. Parts are gradually brought back to room temperature at a specific rate. This prevents thermal shock, which can cause cracking, and locks in the desired microstructure and material characteristics.

The Core Advantage: Consistency at Scale

Combining these processes into one automated flow delivers significant operational advantages over using separate batch furnaces for each step. The primary benefit is achieving unparalleled consistency across massive production volumes.

Unwavering Process Repeatability

Because every part follows the identical path through the same thermal zones, batch-to-batch variation is virtually eliminated. This is a crucial factor for quality control in industries like medical, aerospace, and automotive, where part performance must be absolutely reliable.

Maximized Throughput

A continuous furnace operates without interruption. There is no time lost loading, unloading, heating, and cooling the furnace for individual batches. This continuous flow results in a much higher production output compared to a series of batch operations.

Optimized Energy and Atmosphere Consumption

Maintaining stable temperatures in dedicated zones is far more energy-efficient than repeatedly heating and cooling an entire batch furnace. Likewise, the consumption of specialized atmosphere gases (like nitrogen or hydrogen) is lower and more consistent, reducing operational costs.

Understanding the Trade-offs

While powerful, a continuous furnace is not the universal solution for all thermal processing needs. Its design creates specific limitations that must be understood.

Reduced Flexibility

These furnaces are optimized for one specific, high-volume production run. Changing the process—for instance, adjusting the temperature profile for a different material or part geometry—is a complex and time-consuming task. They are poorly suited for research, development, or high-mix, low-volume manufacturing.

Higher Initial Investment

Continuous furnaces are large, complex systems that represent a significant capital expenditure. The initial cost is substantially higher than that of multiple, smaller batch furnaces.

The "Single Point of Failure" Risk

If a continuous furnace requires maintenance or experiences a failure, the entire production line it serves comes to a halt. A manufacturing setup using multiple batch furnaces offers more redundancy, as one furnace can be taken offline without stopping all production.

Is a Continuous Furnace Right for Your Operation?

Choosing between a continuous and a batch system depends entirely on your production goals and business model.

- If your primary focus is high-volume manufacturing: A continuous furnace will deliver the lowest cost-per-part and the highest level of consistency for a stable, long-running product line.

- If your primary focus is R&D or high-mix production: The flexibility and lower initial cost of batch furnaces are far more suitable for developing new processes or handling many different small jobs.

- If your primary focus is absolute quality control: The identical thermal journey for every part in a continuous furnace is a powerful advantage for eliminating process variability and ensuring uniform quality at scale.

Understanding this fundamental trade-off between throughput and flexibility is the key to selecting the right thermal processing technology for your manufacturing goals.

Summary Table:

| Process Step | Function | Key Benefit |

|---|---|---|

| Debinding Zone | Removes polymer binders at low temperatures | Prevents defects in final parts |

| Sintering Zone | Fuses metal/ceramic particles at high heat | Achieves final density and mechanical properties |

| Cooling Zone | Controls gradual temperature reduction | Prevents thermal shock and locks in microstructure |

Ready to boost your production efficiency with tailored furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in high-volume manufacturing or need flexible options, our expertise ensures optimal performance and cost savings. Contact us today to discuss how we can enhance your thermal processing workflows!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput