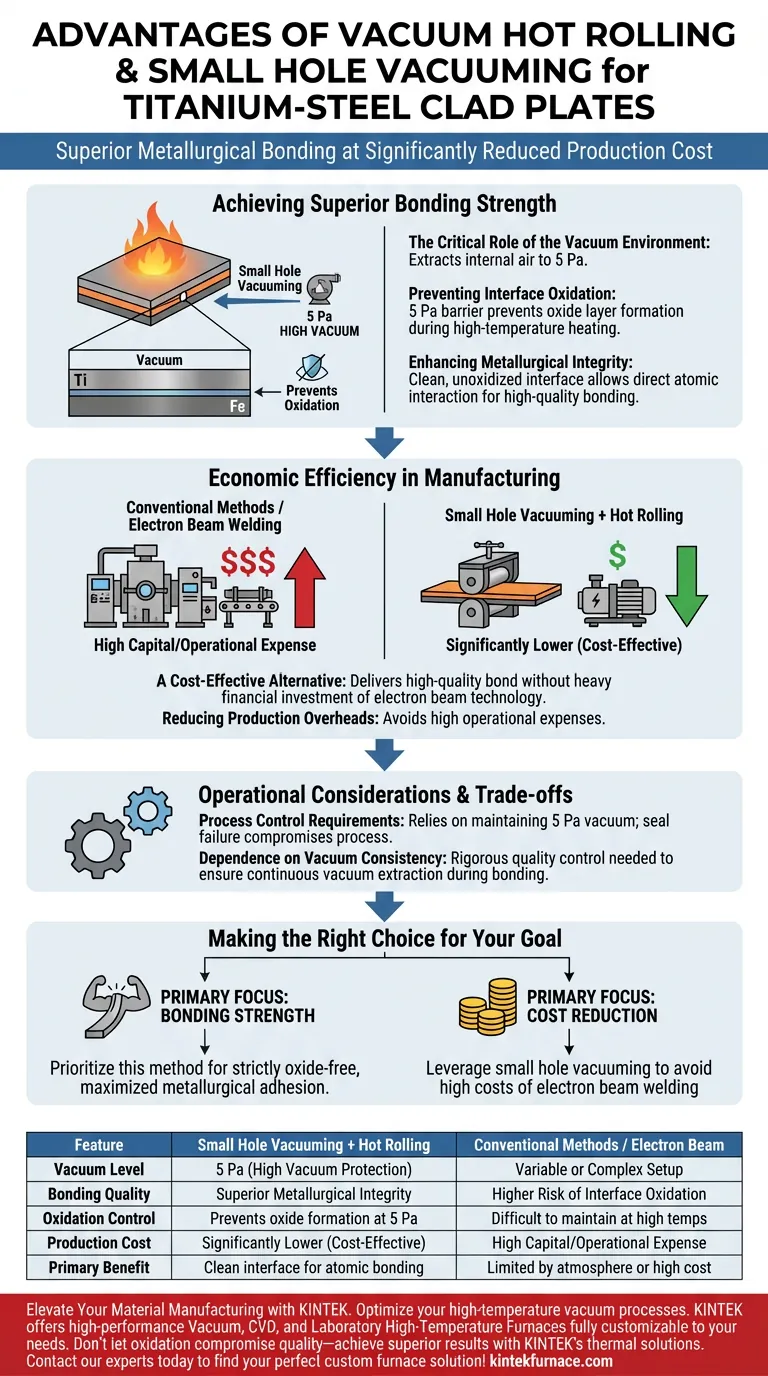

The primary advantage of combining vacuum hot rolling with the small hole vacuuming method is the achievement of superior metallurgical bonding at a significantly reduced production cost. This technique creates a pristine, high-vacuum environment that eliminates internal air, preventing oxidation during the heating process and ensuring a stronger interface between the titanium and steel layers compared to standard methods.

By reaching a vacuum level of 5 Pa, this process effectively shields the metal interface from oxidation during high-temperature heating. This results in robust structural integrity while avoiding the high operational expenses associated with vacuum electron beam welding.

Achieving Superior Bonding Strength

The Critical Role of the Vacuum Environment

The core technical advantage of this method lies in its ability to extract internal air from the billet effectively. By utilizing the small hole vacuuming technique, manufacturers can achieve a vacuum level of 5 Pa.

Preventing Interface Oxidation

Titanium and steel are highly reactive at elevated temperatures. Presence of oxygen during the heating phase typically results in the formation of oxide layers that weaken the bond.

The 5 Pa vacuum environment acts as a protective barrier. It ensures that the interface remains clean and unoxidized throughout the heating process.

Enhancing Metallurgical Integrity

Because the interface is protected from oxidation, the two metals can interact directly at the atomic level. This facilitates high-quality metallurgical bonding.

The result is a clad plate with significantly enhanced bonding strength, ensuring the material performs reliably under stress.

Economic Efficiency in Manufacturing

Reducing Production Overheads

High-performance clad plates often require expensive manufacturing techniques to ensure quality. A common alternative is vacuum electron beam welding.

However, electron beam welding is a complex, resource-intensive process that drives up manufacturing costs.

A Cost-Effective Alternative

The combination of vacuum hot rolling and small hole vacuuming offers a distinct economic advantage. It delivers the necessary high-quality bond without the heavy financial investment required for electron beam technology.

This makes the process highly attractive for large-scale production where keeping unit costs low is a priority.

Operational Considerations and Trade-offs

Process Control Requirements

While this method is cost-effective, it relies heavily on maintaining the specific vacuum level of 5 Pa.

Any failure to seal the small hole effectively or achieve the target pressure can compromise the vacuum. This would allow oxidation to occur, negating the benefits of the process.

Dependence on Vacuum Consistency

Success is dictated by the consistency of the vacuum extraction. Unlike electron beam welding, which applies energy locally, this method treats the entire internal billet environment.

Therefore, rigorous quality control is necessary to ensure the vacuum is maintained until the bonding process is complete.

Making the Right Choice for Your Goal

To determine if this manufacturing route aligns with your project requirements, consider the following technical priorities:

- If your primary focus is bonding strength: Prioritize this method to ensure the titanium-steel interface remains strictly oxide-free, maximizing metallurgical adhesion.

- If your primary focus is cost reduction: Leverage the small hole vacuuming technique to avoid the high capital and operational costs associated with vacuum electron beam welding.

This approach effectively bridges the gap between high-performance material specifications and the need for economical manufacturing processes.

Summary Table:

| Feature | Small Hole Vacuuming + Hot Rolling | Conventional Methods / Electron Beam |

|---|---|---|

| Vacuum Level | 5 Pa (High Vacuum Protection) | Variable or Complex Setup |

| Bonding Quality | Superior Metallurgical Integrity | Higher Risk of Interface Oxidation |

| Oxidation Control | Prevents oxide formation at 5 Pa | Difficult to maintain at high temps |

| Production Cost | Significantly Lower (Cost-Effective) | High Capital/Operational Expense |

| Primary Benefit | Clean interface for atomic bonding | Limited by atmosphere or high cost |

Elevate Your Material Manufacturing with KINTEK

Are you looking to optimize your high-temperature vacuum processes? Backed by expert R&D and precision manufacturing, KINTEK offers high-performance Vacuum, CVD, and Laboratory High-Temperature Furnaces designed to meet the rigorous demands of advanced material engineering.

Whether you are developing titanium-steel clad plates or specialized metallurgical bonds, our systems are fully customizable to your unique research and production needs. Don't let oxidation compromise your quality—achieve superior results with KINTEK's industry-leading thermal solutions.

Contact our experts today to find your perfect custom furnace solution!

Visual Guide

References

- Juan Pu, Yunxia Chen. Effect of Heat Treatment Temperature on the Microstructure and Properties of Titanium-Clad Steel Plate Prepared by Vacuum Hot Rolling. DOI: 10.3390/coatings14091096

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a Rapid Thermal Processing (RTP) furnace necessary for diode fabrication? Achieve Stable Ohmic Contacts

- What is the function of placing a Nickel Mesh in a reactor? Maximizing Heat in Nickel-Hydrogen Systems

- How is mechanochemical grinding used in lithium battery recovery? Unlock Efficient Solid-State Material Repair

- What role does phosphoric acid (H3PO4) play during the chemical activation stage of sawdust? Boost Porosity & Efficiency

- What are the technical advantages of using an ALD system over PVD? Achieve Precise Ge:ZnO Thin Film Fabrication

- Why is a constant temperature drying oven necessary during the preparation of porous activated carbon? Key Benefits

- How does a programmable high-temperature furnace improve the control of cooling rates? Enhance Ceramic Part Integrity

- Why is a high-precision mass flow controller essential for long-term restart performance testing of catalysts?