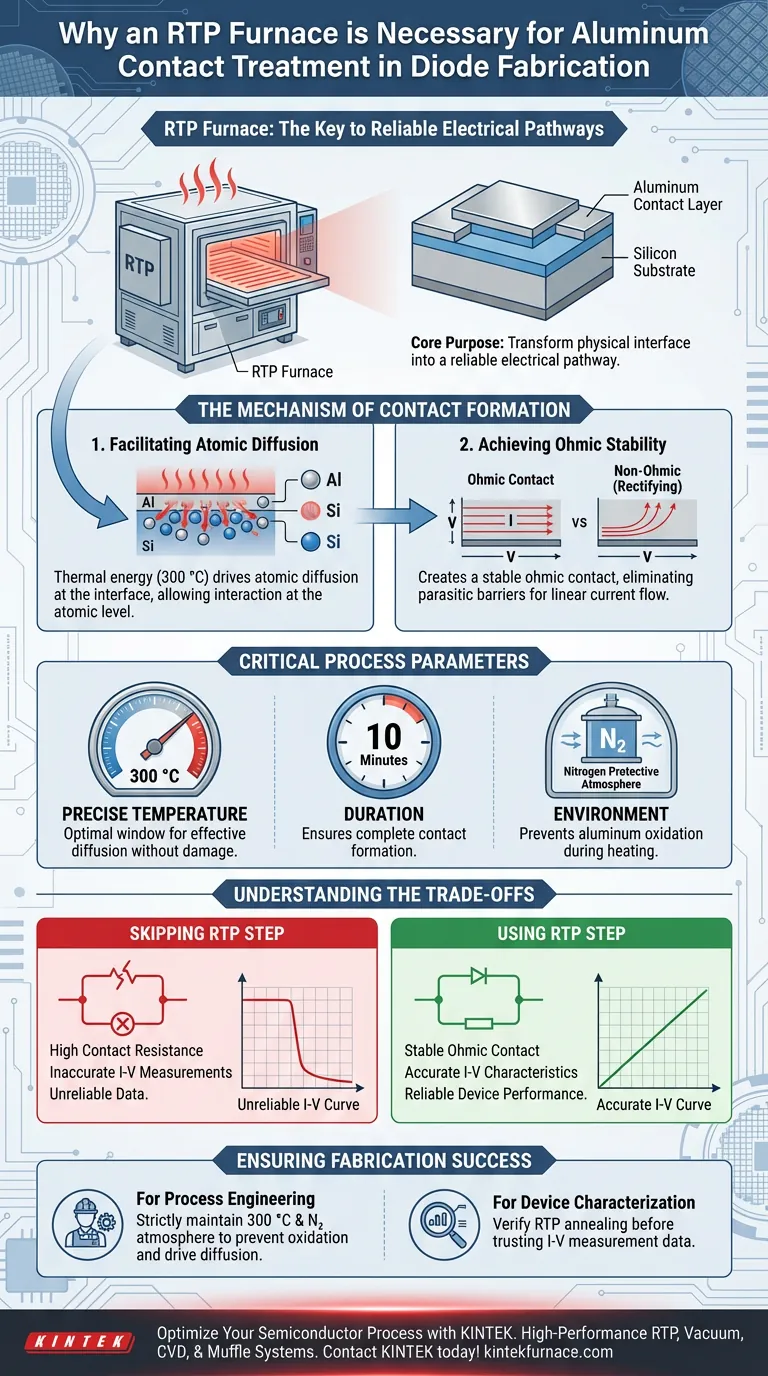

The Rapid Thermal Processing (RTP) furnace is essential for diode fabrication because it provides the precise thermal energy required to finalize the electrical connection between the metal and the semiconductor. By subjecting the aluminum contact layer to 300 °C for 10 minutes, the furnace drives atomic diffusion at the interface. This step is non-negotiable for reducing contact resistance and creating a stable ohmic contact.

The core purpose of the RTP step is to transform a physical interface into a reliable electrical pathway. Without the atomic diffusion facilitated by this annealing process, the contact resistance remains too high, rendering accurate current-voltage (I-V) measurements impossible.

The Mechanism of Contact Formation

Facilitating Atomic Diffusion

The primary role of the RTP furnace is to facilitate atomic diffusion at the aluminum-silicon interface. Simply depositing aluminum onto silicon does not immediately create a high-quality electrical connection.

Thermal energy is required to mobilize the atoms at the junction. The RTP furnace provides this energy, allowing the aluminum and silicon to interact at the atomic level.

Achieving Ohmic Stability

This diffusion process is critical for establishing a stable ohmic contact. An ohmic contact allows current to flow linearly in accordance with Ohm's law, without rectifying behavior at the contact itself.

By ensuring the contact is ohmic, you eliminate parasitic barriers to current flow. This ensures the device functions as intended rather than being limited by the quality of its terminals.

Critical Process Parameters

Precise Temperature and Timing

The reference process dictates a specific annealing protocol: 300 °C for 10 minutes. This specific window provides sufficient energy to lower resistance without damaging the device structure.

Adhering to these parameters ensures the diffusion is controlled and effective. Deviating from this time or temperature could result in incomplete contact formation.

Environmental Control

The annealing process must occur under a nitrogen protective atmosphere. The RTP furnace allows for this controlled environment, which is vital for the success of the treatment.

Nitrogen prevents oxidation of the aluminum during the heating phase. Oxidation at this stage would degrade the contact quality and increase resistance, countering the goal of the annealing process.

Understanding the Trade-offs

The Cost of Omission

Skipping the RTP step is a critical error in diode fabrication. Without this thermal treatment, the contact resistance remains effectively untreated.

High contact resistance introduces voltage drops that are not part of the diode's intrinsic behavior. This obscures the true performance of the device.

Impact on Characterization

The most significant trade-off involves measurement accuracy. The formation of a stable ohmic contact is critical for the accurate measurement of current-voltage (I-V) characteristics.

If the contact is not stable, data collected during testing will be unreliable. You will be measuring the resistance of the bad contact rather than the physics of the diode.

Ensuring Fabrication Success

To ensure your diode fabrication yields functional, testable devices, consider the following based on your specific role:

- If your primary focus is process engineering: Strictly maintain the 300 °C temperature profile and nitrogen atmosphere to prevent oxidation while driving diffusion.

- If your primary focus is device characterization: Verify that the RTP annealing step has been completed before trusting any I-V measurement data.

A properly annealed aluminum contact is the bridge between a theoretical semiconductor structure and a working electronic device.

Summary Table:

| Parameter | Specification | Purpose |

|---|---|---|

| Temperature | 300 °C | Provides energy for atomic diffusion |

| Duration | 10 Minutes | Ensures complete contact formation |

| Atmosphere | Nitrogen ($N_2$) | Prevents aluminum oxidation |

| Goal | Ohmic Contact | Enables linear current flow and accuracy |

Optimize Your Semiconductor Process with KINTEK

Precision thermal processing is the difference between a failed measurement and a high-performance device. At KINTEK, we understand that every degree and every second counts. Backed by expert R&D and manufacturing, we provide high-performance RTP, Vacuum, CVD, and Muffle systems designed to deliver the precise environmental control and temperature stability your lab demands.

Whether you are refining aluminum contact layers or developing next-generation semiconductor structures, our customizable lab furnaces ensure your research is supported by reliable, repeatable results.

Ready to upgrade your fabrication capabilities? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- G. Naga Raju, P.R. Sekhar Reddy. Microstructural and Current-voltage Characteristics in Mo/HfO2/n‑Si Based Metal-Insulator-Semiconductor (MIS) Diode using Different Methods for Optoelectronic Device Applications. DOI: 10.36948/ijfmr.2024.v06i02.16012

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How does microstructural observation assist in optimizing LATP sintering? Master High-Density Material Processing

- What factors are assessed during the evaluation for an Industrial Furnace project? Optimize Your Thermal Process

- How do laboratory thermostatic baths contribute to the phosphoric acid treatment of 3Y-TZP ceramics? Boost Bioactivity

- What is the significance of pre-equilibrating samples in silicate studies? Maximize Experimental Efficiency

- Why is Water Quenching Critical for Metastable Phases in Titanium? Unlock High-Performance Alloy Strength

- What is the purpose of performing a 600 degree Celsius annealing treatment? Enhance AZO Thin Film Stability

- Why is a furnace with programmed temperature control required for catalyst regeneration? Ensure Catalyst Stability

- What is the primary function of compacting PVC and metal oxide mixtures? Enhancing Dechlorination Efficiency