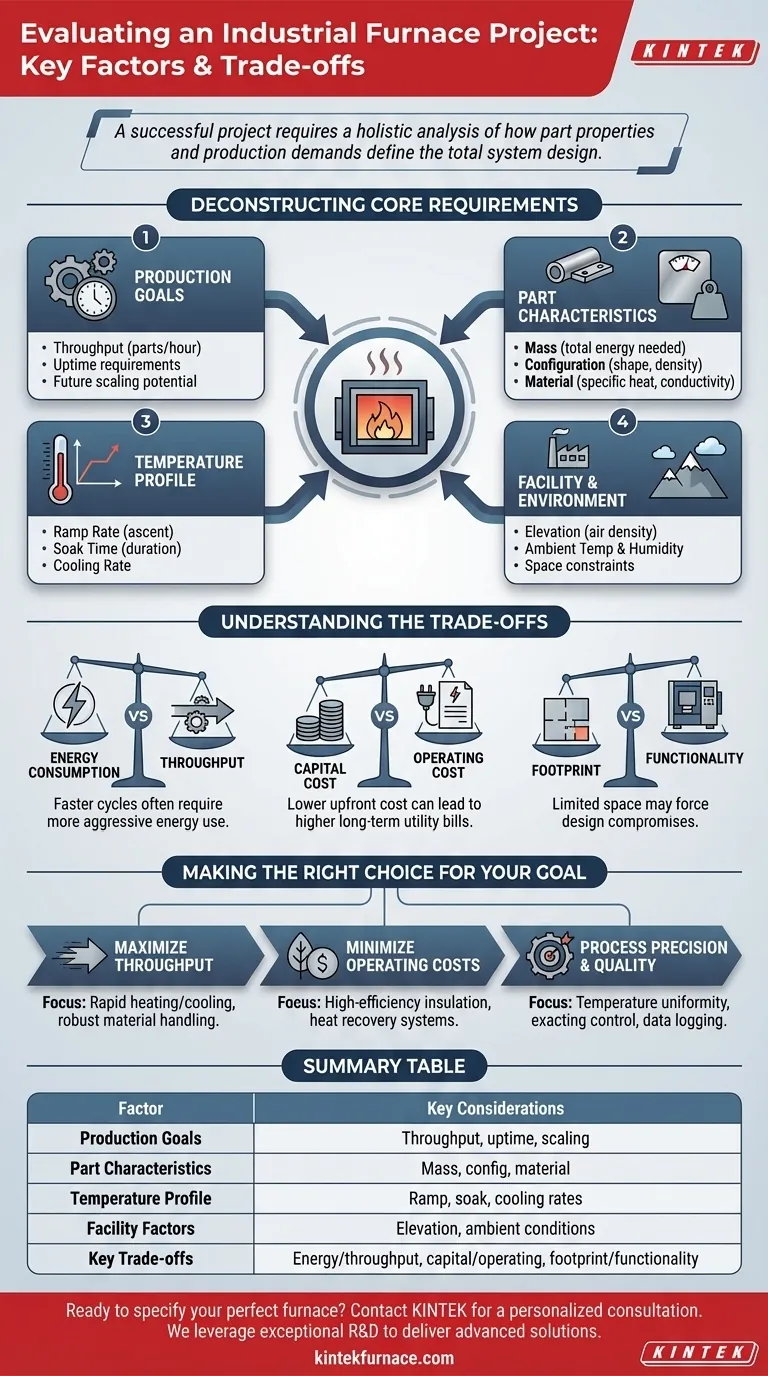

To properly evaluate an industrial furnace project, you must assess a specific set of operational and physical parameters. The core factors include production goals, the mass and physical configuration of the parts being processed, the required temperature profile, and the environmental conditions of the facility, such as its elevation.

A successful furnace project goes beyond specifying a temperature and size. It requires a holistic analysis of how the part's properties and the production demands collectively define the total energy and system design needed to achieve a reliable and efficient thermal process.

Deconstructing the Core Requirements

A furnace is not a simple oven; it is an engineered system where every component is specified to meet a precise thermal processing goal. Understanding how each requirement influences the final design is critical to avoiding costly errors in performance and efficiency.

Production Goals

Your production goals set the pace for the entire system. This is not just about the number of parts per hour but also the required uptime and potential for future scaling.

This data directly informs the furnace's size, the power of its heating system, and the design of its material handling components (e.g., conveyor belt speed or batch loading mechanisms).

Part Characteristics (Mass, Configuration, and Construction)

The part itself is the single most important variable. Its physical properties dictate how it will behave inside the furnace.

Part mass determines the total amount of energy (BTUs or kWh) required to raise its temperature. A heavier part requires significantly more energy and time to heat than a lighter one.

Part configuration—its shape, density, and complexity—affects how it absorbs heat. A dense, solid block will heat much slower than a thin, hollow structure, as heat must penetrate to its core.

The material of construction (e.g., steel, aluminum, ceramic) is also crucial due to its specific heat capacity and thermal conductivity, which define how quickly it accepts and distributes thermal energy.

The Temperature Profile

The temperature profile is the part's prescribed thermal journey. It's far more than just a peak temperature.

This profile includes the rate of temperature ascent (ramp rate), the duration at a specific temperature (soak time), and the rate of cooling.

Each phase dictates a different aspect of the furnace design. A rapid ramp rate requires a high-power heating system, while a long soak time demands excellent insulation and precise temperature controls to ensure uniformity and prevent overshoot.

Facility and Environmental Factors

The furnace does not operate in a vacuum. Its surrounding environment directly impacts its performance and safety.

The facility's elevation is a critical factor for fuel-fired furnaces. Higher elevations have lower air density, which means less oxygen is available for combustion. This requires adjustments to the burner and air supply systems to ensure efficient and complete fuel burning.

Ambient temperature and humidity can also affect heating element life, control cabinet cooling, and overall energy efficiency.

Understanding the Trade-offs

Specifying an industrial furnace is an exercise in balancing competing priorities. Being aware of these trade-offs is essential for making an informed investment.

Energy Consumption vs. Throughput

Increasing throughput by shortening cycle times often requires a more aggressive application of energy. This can lead to higher energy costs per part.

The key is to find the optimal balance where production targets are met without excessive energy waste, often through efficient heat recovery systems or optimized insulation.

Capital Cost vs. Operating Cost

A furnace with a lower upfront cost may be tempting, but it can lead to higher long-term expenses.

Cheaper models may use less effective insulation or less efficient heating systems, resulting in continuous energy loss and higher utility bills for years. Investing more in superior insulation and heat recovery can yield a significantly lower total cost of ownership.

Footprint vs. Functionality

The physical space available in your facility is a hard constraint. A larger furnace might offer better temperature uniformity and efficiency, but it may not fit.

This can force compromises in design, such as vertical configurations or more complex material handling systems, which can impact maintenance access and operational workflow.

Making the Right Choice for Your Goal

To ensure your furnace specification aligns with your business objectives, clearly define your primary driver for the investment.

- If your primary focus is maximizing throughput: Your specification must prioritize rapid heating and cooling capabilities and robust material handling systems.

- If your primary focus is minimizing long-term operating costs: Emphasize high-efficiency insulation, advanced control systems, and heat recovery technologies, even if it increases the initial capital investment.

- If your primary focus is process precision and part quality: Center your requirements on temperature uniformity, exacting control over the entire thermal profile, and data logging capabilities.

A thorough, well-defined evaluation is the foundation of a successful and profitable thermal processing operation.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Production Goals | Throughput, uptime, future scaling needs |

| Part Characteristics | Mass, configuration, material of construction |

| Temperature Profile | Ramp rate, soak time, cooling rate |

| Facility Factors | Elevation, ambient temperature, humidity |

| Key Trade-offs | Energy vs. throughput, capital vs. operating cost, footprint vs. functionality |

Ready to specify an industrial furnace that perfectly balances your production goals, energy efficiency, and budget?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to deliver advanced, high-performance furnace solutions. Whether you need a standard Muffle, Tube, or Rotary Furnace, or a custom-designed Vacuum, Atmosphere, or CVD/PECVD System, our deep customization capability ensures your unique thermal processing requirements are met precisely.

Contact our experts today for a personalized consultation and let us help you build the foundation for a successful and profitable thermal processing operation.

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does the quartz tube furnace minimize heat loss? Double Insulation for Energy Efficiency

- What are the common applications of quartz tube furnaces? Unlock Precision in High-Temp Processing

- How does the sealing mechanism in Quartz Tube Furnaces differ from traditional systems? Discover Advanced Sealing for Reliable Results

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing

- How does the work process of a quartz tube furnace typically proceed? Master Precision Heating for Advanced Materials