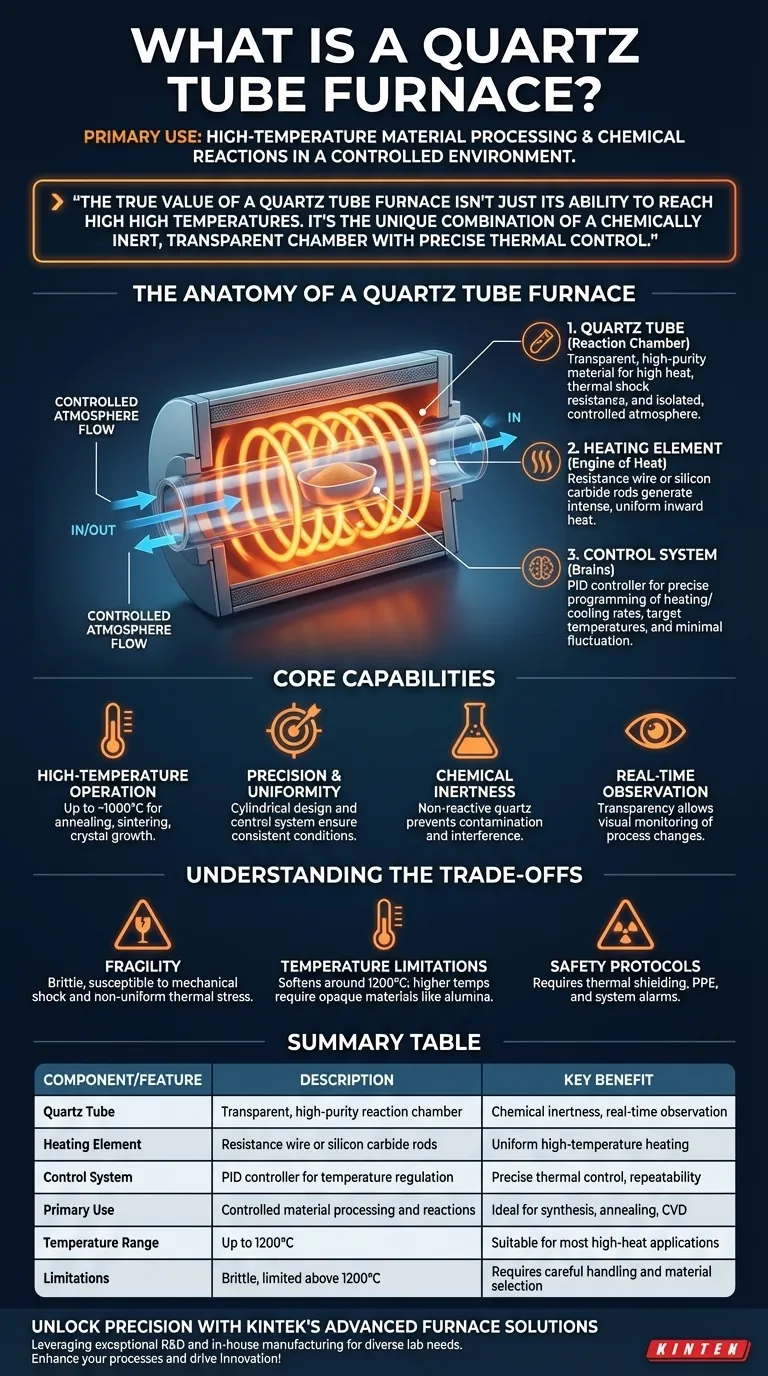

At its core, a quartz tube furnace is a high-temperature heating device that uses a transparent quartz tube as a sealed reaction chamber. Its primary use is to process materials or induce chemical reactions in a highly controlled and observable environment, making it indispensable in materials science, chemistry, and semiconductor manufacturing.

The true value of a quartz tube furnace isn't just its ability to reach high temperatures. It's the unique combination of a chemically inert, transparent chamber with precise thermal control, allowing for processes that are otherwise impossible.

The Anatomy of a Quartz Tube Furnace

Understanding how this device works requires looking at its three essential components, which function together to create a controlled heating environment.

The Quartz Tube: The Reaction Chamber

The furnace's central component is a tube made of high-purity quartz. This material is chosen for its ability to withstand high temperatures and rapid temperature changes (thermal shock).

Its primary function is to house the sample, creating an isolated environment where the atmosphere can be carefully controlled, for example, by introducing inert gases or creating a vacuum.

The Heating Element: The Engine of Heat

Heating elements, typically made of resistance wire or silicon carbide rods, are arranged around the outside of the quartz tube. When electricity passes through them, they generate the intense, uniform heat required for processing.

The design ensures the heat radiates inward, providing even temperature distribution along the length of the sample inside the tube.

The Control System: The Brains of the Operation

A sophisticated temperature control system is crucial for a tube furnace's function. Modern systems often use a PID (Proportional-Integral-Derivative) controller.

This allows researchers to program precise heating and cooling rates, set specific target temperatures, and hold them with minimal fluctuation, ensuring process repeatability and accuracy.

Core Capabilities and Why They Matter

The specific features of a quartz tube furnace directly enable its most important scientific and industrial applications.

High-Temperature Operation

These furnaces are designed to operate consistently at temperatures often exceeding 1000°C. This capability is fundamental for processes like annealing metals, sintering ceramics, and growing crystals.

Precision and Uniformity

The combination of a cylindrical design and a modern control system allows for exceptionally uniform heating. This ensures that an entire sample is processed under the exact same thermal conditions, which is critical for consistent material properties.

Chemical Inertness

Quartz is highly non-reactive. This inertness prevents the tube itself from contaminating the sample or interfering with a chemical reaction, which is essential when working with highly pure or reactive substances.

Real-Time Observation

The transparency of the quartz tube is a unique and powerful advantage. It allows operators and scientists to visually monitor the process in real-time, observing color changes, melting, or other physical transformations as they happen.

Understanding the Trade-offs

While powerful, a quartz tube furnace is a specialized tool with specific limitations that must be respected.

The Fragility of Quartz

Quartz is a form of glass and is inherently brittle. It is susceptible to mechanical shock and can crack if mishandled or subjected to extreme, non-uniform thermal stress. Care must be taken during setup and operation.

Temperature Limitations vs. Other Materials

While excellent for many high-temperature applications, quartz begins to soften at temperatures approaching 1200°C. For processes requiring even higher heat, furnace tubes made from materials like alumina are necessary, but this comes at the cost of transparency.

The Importance of Safety Protocols

Operating any device at these temperatures poses inherent risks. Proper safety measures, including thermal shielding, personal protective equipment, and system alarms for over-temperature conditions, are not optional—they are essential for safe operation.

Making the Right Choice for Your Goal

Selecting and using a quartz tube furnace effectively depends entirely on your specific objective.

- If your primary focus is material synthesis (like CVD): Its ability to maintain a pure, controlled atmosphere is the most critical feature.

- If your primary focus is process observation: The transparency of the quartz tube is its defining advantage over other furnace types.

- If your primary focus is ultra-high temperature processing (>1200°C): A tube furnace is still the right tool, but you must opt for a tube made of alumina or another advanced ceramic.

This tool empowers you to control matter at high temperatures with exceptional precision.

Summary Table:

| Component/Feature | Description | Key Benefit |

|---|---|---|

| Quartz Tube | Transparent, high-purity reaction chamber | Chemical inertness and real-time observation |

| Heating Element | Resistance wire or silicon carbide rods | Uniform high-temperature heating |

| Control System | PID controller for temperature regulation | Precise thermal control and repeatability |

| Primary Use | Controlled material processing and reactions | Ideal for synthesis, annealing, and CVD |

| Temperature Range | Up to 1200°C | Suitable for most high-heat applications |

| Limitations | Brittle, limited above 1200°C | Requires careful handling and material selection |

Unlock Precision in Your Laboratory with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements.

Whether you're in materials science, chemistry, or semiconductor manufacturing, our quartz tube furnaces offer superior control, uniformity, and real-time observation for reliable results. Contact us today to discuss how we can enhance your processes and drive innovation in your lab!

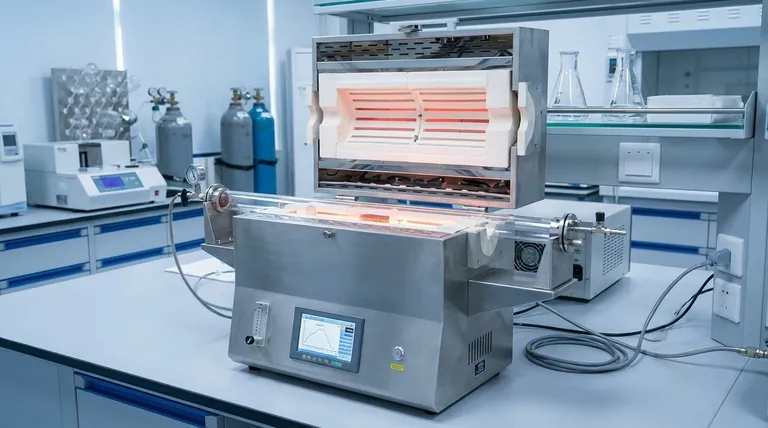

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency