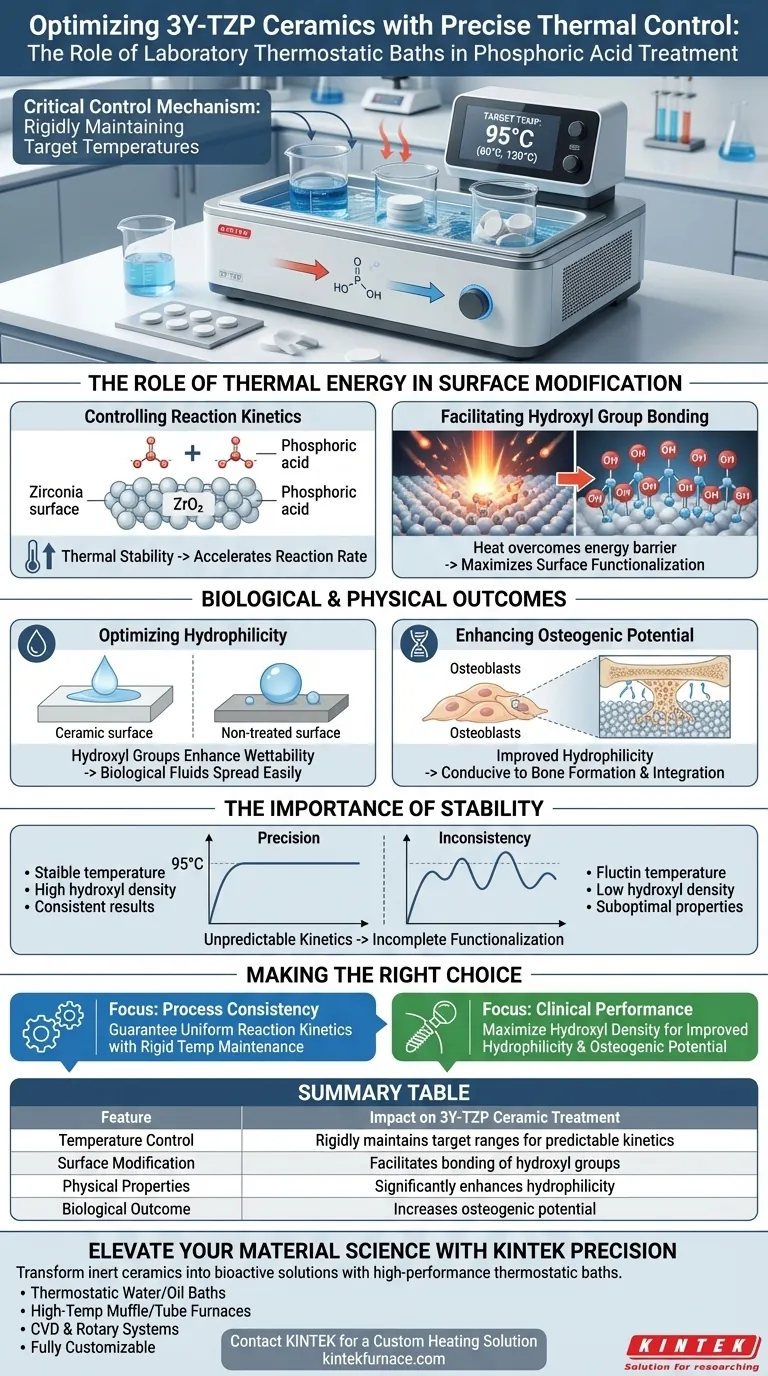

Laboratory thermostatic baths and heating devices act as the critical control mechanism for the surface modification of 3Y-TZP ceramics. By rigidly maintaining phosphoric acid solutions at specific target temperatures—such as 60°C, 95°C, or 120°C—these devices ensure the precise thermal energy supply required to drive the chemical reaction between the acid and the zirconia surface.

Temperature is the primary variable that governs the reaction kinetics between phosphoric acid and zirconia. Thermostatic devices provide the necessary thermal stability to accelerate the bonding of hydroxyl groups, which is the fundamental mechanism for optimizing the material's biological performance.

The Role of Thermal Energy in Surface Modification

Controlling Reaction Kinetics

The interaction between phosphoric acid and 3Y-TZP ceramics is highly dependent on reaction kinetics. Temperature does not merely sustain the solution; it acts as a catalyst for the chemical process.

Thermostatic devices ensure that the thermal energy supply is constant. This stability is required to accelerate the reaction rate to a predictable and effective level.

Facilitating Hydroxyl Group Bonding

The primary goal of the thermal treatment is to alter the surface chemistry of the ceramic. The heat supplied by the device facilitates the bonding of hydroxyl functional groups to the zirconia surface.

Without precise heating, the energy barrier for this bonding process might not be overcome efficiently. The device ensures the environment is energetic enough to maximize this surface functionalization.

Biological and Physical Outcomes

Optimizing Hydrophilicity

The presence of hydroxyl groups directly influences the physical properties of the ceramic. Specifically, these groups significantly enhance the hydrophilicity (wettability) of the surface.

A hydrophilic surface allows biological fluids to spread more easily across the implant material. This is a direct result of the chemical changes driven by the heated acid treatment.

Enhancing Osteogenic Potential

The ultimate downstream benefit of this process is biological. By optimizing hydrophilicity through controlled heating, the osteogenic potential of the 3Y-TZP ceramic is improved.

This means the material becomes more conducive to bone formation and integration. The thermostatic device, therefore, plays a vital role in determining the clinical success of the ceramic implant.

The Importance of Stability

Precision vs. Inconsistency

The effectiveness of phosphoric acid treatment relies on the stability of the temperature.

If the temperature fluctuates or fails to reach the targets (e.g., 60, 95, or 120°C), the reaction kinetics become unpredictable. This can lead to incomplete surface functionalization and suboptimal biological properties.

Making the Right Choice for Your Goal

To ensure the successful treatment of 3Y-TZP ceramics, consider the following regarding your thermal equipment:

- If your primary focus is Process Consistency: Ensure your device can rigidly maintain the specific target temperatures (60°C, 95°C, or 120°C) without fluctuation to guarantee uniform reaction kinetics.

- If your primary focus is Clinical Performance: Prioritize thermal precision to maximize the density of hydroxyl groups, as this directly correlates to improved hydrophilicity and osteogenic potential.

Precise thermal control is not just a procedural requirement; it is the enabling factor that transforms an inert ceramic into a bioactive material.

Summary Table:

| Feature | Impact on 3Y-TZP Ceramic Treatment |

|---|---|

| Temperature Control | Rigidly maintains target ranges (60°C, 95°C, 120°C) for predictable kinetics |

| Surface Modification | Facilitates bonding of hydroxyl groups to the zirconia surface |

| Physical Properties | Significantly enhances hydrophilicity and surface wettability |

| Biological Outcome | Increases osteogenic potential for better bone formation and integration |

Elevate Your Material Science with KINTEK Precision

Precise thermal energy is the key to transforming inert ceramics into bioactive medical solutions. KINTEK provides high-performance laboratory heating systems and thermostatic baths designed to deliver the rigid temperature stability required for critical 3Y-TZP surface modifications.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of equipment, including:

- Thermostatic Water/Oil Baths for precise acid treatment

- High-Temp Muffle, Tube, and Vacuum Furnaces

- CVD & Rotary Systems for advanced surface engineering

All our systems are fully customizable to meet your unique research or manufacturing needs. Ensure consistent reaction kinetics and superior clinical outcomes for your ceramic implants today.

Contact KINTEK for a Custom Heating Solution

Visual Guide

References

- Satoshi KOBAYASHI, Takumi Sekine. Effect of bioactivation treatment using phosphoric acid on mechanical properties and osteogenesis for 3Y-TZP. DOI: 10.1299/mej.24-00376

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is a reaction vessel with pressure control necessary for Ru nanoparticle synthesis? Achieve Precision Morphology

- What is the function of a high-pressure reactor in SHS? Optimize Tungsten Carbide Synthesis with Precision

- How does a resistance heating furnace contribute to Al/Cu bimetallic interface preparation? Expert Thermal Solutions

- How does the thermal treatment enhance the mechanical properties of AZO and ZnO coatings? Boost Durability & Hardness

- Why Roast SiC Particles for 2024Al/Gr/SiC Composites? Optimize Surface Modification and Bonding

- What is the role of a vacuum drying oven in processing MOF precursors? Preserve Integrity for Co-HCC Synthesis

- What are the key advantages of using an annealing furnace? Enhance Material Quality and Manufacturing Efficiency

- What are the advantages of continuous furnaces? Boost Efficiency and Cut Costs in High-Volume Production