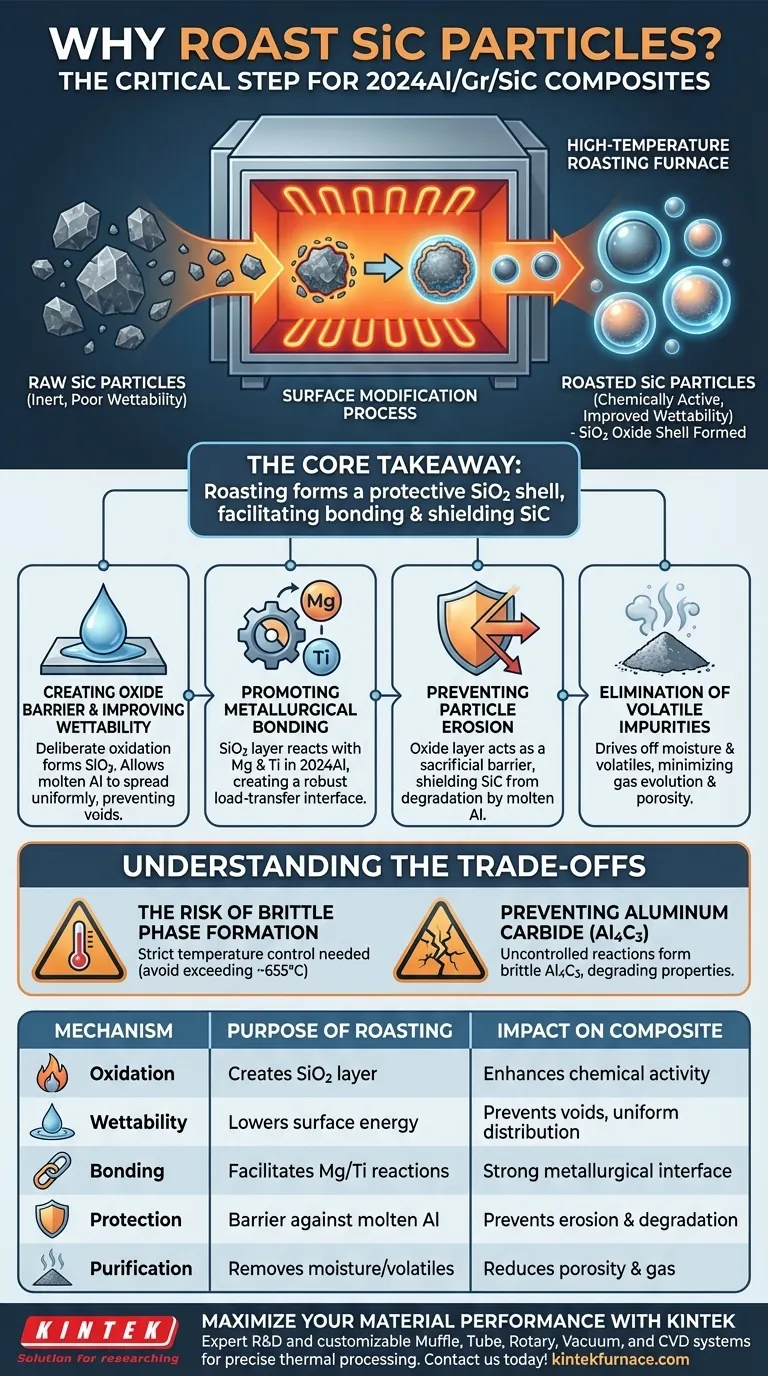

Roasting Silicon Carbide (SiC) particles is a critical surface modification step primarily intended to generate a coherent silicon dioxide (SiO2) layer on the particle surface. This high-temperature treatment transforms the SiC from an inert, difficult-to-wet ceramic into a chemically active reinforcement ready for integration into the 2024 aluminum alloy matrix.

The Core Takeaway Raw SiC particles suffer from poor wettability and are prone to erosion when in contact with molten aluminum. Roasting solves this by forming a protective SiO2 oxide shell that facilitates strong metallurgical bonding with alloying elements (like Mg and Ti) while shielding the SiC from degradation.

The Mechanics of Surface Modification

Creating the Oxide Barrier

The primary function of roasting is the deliberate oxidation of the SiC surface. By exposing the particles to high temperatures, a thin, coherent layer of silicon dioxide (SiO2) is formed.

Improving Wettability

Molten aluminum does not naturally "wet" or spread over raw silicon carbide effectively. The creation of the SiO2 layer fundamentally changes the surface energy of the particle. This allows the aluminum matrix to spread uniformly across the reinforcement, preventing voids and ensuring structural continuity.

Strengthening the Interface

Promoting Metallurgical Bonding

The SiO2 layer is not just a passive coating; it serves as a reaction site. It enables chemical reactions with specific elements within the 2024 aluminum alloy, specifically Magnesium (Mg) and Titanium (Ti). These elements react with the oxide layer to form a robust metallurgical bonding interface, which is essential for transferring load between the soft matrix and the hard reinforcement.

Preventing Particle Erosion

Without protection, SiC particles can be eroded or degraded by direct contact with molten aluminum. The oxide layer acts as a sacrificial or protective barrier. It prevents the aggressive aluminum melt from directly attacking the SiC core, preserving the geometry and mechanical integrity of the reinforcement particles.

Elimination of Volatile Impurities

While the primary goal is oxidation, the heating process serves a secondary purification role. Similar to preheating processes used for other powders, high-temperature treatment drives off adsorbed moisture and volatile impurities. This minimizes gas evolution during the casting or sintering phases, which could otherwise lead to porosity or splashing.

Understanding the Trade-offs

The Risk of Brittle Phase Formation

While the oxide layer is necessary, the subsequent processing temperatures must be strictly controlled. If the temperature during the composite preparation (e.g., vacuum hot pressing) exceeds critical limits (typically around 655°C) or is held too long, the aluminum may react excessively.

Preventing Aluminum Carbide (Al4C3)

The goal is to promote bonding, not total degradation. If the interface reactions are uncontrolled, aluminum can react with carbon to form Aluminum Carbide (Al4C3). This is a brittle, water-soluble phase that significantly degrades the mechanical properties and corrosion resistance of the final composite. The roasted oxide layer helps modulate this reaction, but precise temperature control remains essential.

Making the Right Choice for Your Goal

To maximize the performance of your 2024Al/Gr/SiC composite, align your processing parameters with these objectives:

- If your primary focus is Interface Strength: Ensure the roasting time and temperature are sufficient to create a continuous SiO2 layer, facilitating the reaction with Mg and Ti for maximum load transfer.

- If your primary focus is Microstructural Integrity: Use the heating step to thoroughly dehydrate the powder, preventing gas porosity that compromises the matrix density.

- If your primary focus is Material Longevity: Rely on the oxide layer to shield the SiC from erosion, but strictly monitor subsequent sintering temperatures to avoid forming brittle Al4C3.

Summary: Roasting is not merely about cleaning the particles; it is an active engineering step that creates the chemical bridge required for the aluminum and SiC to function as a unified composite.

Summary Table:

| Mechanism | Purpose of Roasting SiC Particles | Impact on Composite Quality |

|---|---|---|

| Oxidation | Creates a coherent SiO2 surface layer | Enhances chemical activity of inert SiC |

| Wettability | Lowers surface energy for molten aluminum | Prevents voids and ensures uniform distribution |

| Bonding | Facilitates reactions with Mg and Ti | Creates a strong metallurgical interface for load transfer |

| Protection | Acts as a barrier against molten Al attack | Prevents particle erosion and structural degradation |

| Purification | Removes moisture and volatile impurities | Reduces porosity and gas evolution during casting |

Maximize Your Material Performance with KINTEK

Precise interface control in 2024Al/Gr/SiC composites starts with the right thermal processing. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temp furnaces, all fully customizable to meet your unique roasting and sintering needs.

Our advanced high-temperature solutions ensure the precise oxidation and dehydration required to prevent brittle phase formation and enhance metallurgical bonding. Contact us today to discover how our high-precision furnaces can optimize your composite fabrication process!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the objectives of melt stirring and insulation treatment during the Al-5Er-Ti master alloy preparation process?

- What are the advantages of continuous furnaces? Boost Efficiency and Cut Costs in High-Volume Production

- What are the advantages of electric current-assisted TLP bonding? Maximize Efficiency for Inconel 718 Joining

- What roles does a laboratory oven play in biochar production? Enhance Efficiency and Accuracy in Thermal Processing

- What are the core technical advantages of a flash sintering system? Elevate KNN Ceramic Manufacturing Performance

- What are the advantages of heterogeneous catalysts in HTL? Boost Biofuel Quality and Process Efficiency

- What are the primary advantages of using powder metallurgy for Ti and TiZr alloys? Achieve Ultimate Structural Precision

- Why is an electric heating furnace integrated with a capsule-piercing reactor? Ensure Precise Fluid Analysis