The primary advantage of electric current-assisted TLP bonding equipment lies in its ability to utilize Joule heating for rapid thermal cycling, drastically outperforming the slow heating rates of traditional vacuum furnaces. This method significantly increases bonding efficiency and reduces energy consumption while offering precise control over the heat affected zone.

By shifting from bulk heating to localized Joule heating, this technology reduces process times from hours to minutes. Crucially, it preserves the integrity of Inconel 718 by preventing the negative microstructural changes often caused by prolonged exposure to high temperatures.

The Mechanics of Process Efficiency

Leveraging Joule Heating

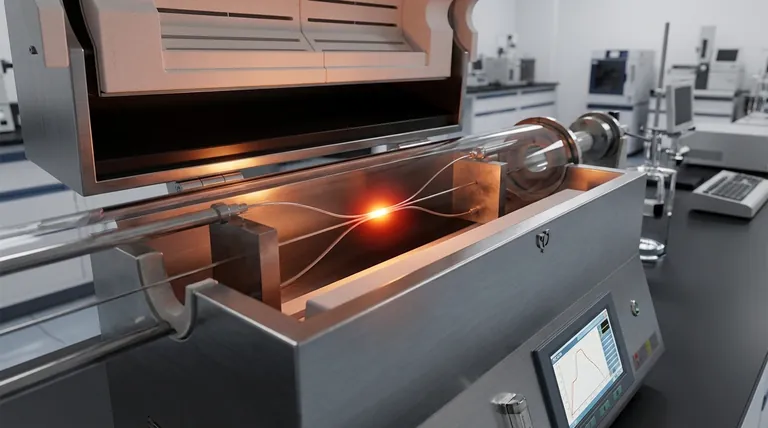

Unlike vacuum furnaces that rely on radiation to heat an entire chamber, electric current-assisted equipment applies heat directly through the component.

This utilizes Joule heating, where the electrical resistance of the material generates heat internally. This allows for immediate energy transfer and rapid temperature escalation.

Drastic Reduction in Cycle Time

Traditional vacuum furnace cycles are often lengthy, sometimes lasting several hours to ensure uniform soaking.

Electric current-assisted bonding achieves rapid heating and cooling rates. This speed significantly shortens the overall bonding cycle, leading to higher throughput and improved operational efficiency.

Lower Energy Consumption

Because the heat is generated within the workpiece rather than the environment, energy waste is minimized.

This direct application of energy results in a far more sustainable process compared to the high energy demands required to maintain vacuum furnace temperatures for extended periods.

Preserving Material Integrity

Advantages of Localized Heating

For ultra-thin capillaries, prolonged exposure to global heat can be detrimental.

Electric current-assisted equipment utilizes localized heating characteristics. This ensures that heat is concentrated exactly where the bond forms, rather than subjecting the entire capillary length to unnecessary thermal stress.

Controlling Microstructure

Inconel 718 is sensitive to prolonged thermal exposure, which can alter its mechanical properties.

The rapid thermal cycle of electric current-assisted bonding minimizes negative impacts on the base metal's microstructure. Specifically, it helps prevent the unwanted precipitation of the gamma double prime phase, a common issue when Inconel 718 is subjected to the slow thermal cycles of traditional furnaces.

Operational Considerations

Managing Thermal Precision

While traditional furnaces offer a stable, "slow-soak" environment, they lack agility.

The shift to electric current-assisted bonding requires acknowledging the move from bulk stability to dynamic precision. The benefit is speed, but the process relies on the precise application of current to ensure the bond forms correctly without overshooting, given the rapid timeframe.

Equipment Footprint and Focus

Vacuum furnaces are generally batch-processing units designed for volume.

Electric current-assisted setups are typically more focused on individual or continuous joining of specific features. This makes them ideal for targeted applications like capillary joining where the specific interaction at the joint interface is more critical than bulk heat treatment.

Making the Right Choice for Your Goal

When selecting between electric current-assisted TLP bonding and traditional vacuum furnaces for Inconel 718 capillaries, consider your primary constraints:

- If your primary focus is microstructure preservation: Choose electric current-assisted bonding to utilize localized heating and avoid gamma double prime phase precipitation.

- If your primary focus is energy and time efficiency: Choose electric current-assisted bonding to exploit Joule heating for significantly faster cycles and reduced power usage.

Ultimately, for ultra-thin Inconel 718 applications, electric current-assisted bonding offers a superior balance of speed and metallurgical protection.

Summary Table:

| Feature | Electric Current-Assisted TLP | Traditional Vacuum Furnace |

|---|---|---|

| Heating Mechanism | Internal Joule Heating | External Radiation/Bulk Heating |

| Cycle Time | Minutes (Rapid) | Hours (Slow) |

| Heat Zone | Localized at Joint | Global Chamber Heating |

| Energy Efficiency | High (Direct Energy Transfer) | Low (Significant Heat Waste) |

| Material Impact | Prevents Gamma Double Prime Phase | Risk of Thermal Microstructure Change |

| Application Focus | Targeted/Continuous Precision | Batch Volume Processing |

Optimize Your Advanced Material Joining with KINTEK

Don't let slow thermal cycles compromise the integrity of your ultra-thin Inconel 718 components. KINTEK provides cutting-edge laboratory solutions and industrial systems designed to meet the most rigorous metallurgical standards. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique research and production needs.

Ready to reduce your cycle times and enhance bond quality? Contact our specialists at KINTEK today to discover how our high-temperature thermal systems can revolutionize your workflow.

References

- Yueshuai Song, Min Wan. Electric Current-Assisted TLP: Bonding of Ultrathin-Walled Inconel 718 Capillaries Temperature Field Simulation and Microstructural Analysis. DOI: 10.1088/1742-6596/2679/1/012015

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the functions of hydrogen gas for graphene on silver? Enhance Crystallinity & Stability

- How is mechanochemical grinding used in lithium battery recovery? Unlock Efficient Solid-State Material Repair

- Why are specific heating pulses applied when monitoring molten metal surface oscillations? Unlock Material Insights

- What is the function of 0.5 mbar nitrogen in sintering? Prevent Chromium Loss for Stronger Cermets

- Why is a nitrogen (N2) purging system necessary for biomass torrefaction? Prevent Combustion and Maximize Biochar Yield

- What is Skin Depth and how does it affect induction heating? Master Frequency Control for Precise Heat

- What is the role of a high-energy ball mill in NiWO4/GO preparation? Master High-Performance Composite Synthesis

- What is the purpose of using an industrial oven for the pretreatment of reinforcement powders? | Enhance Composite Bond