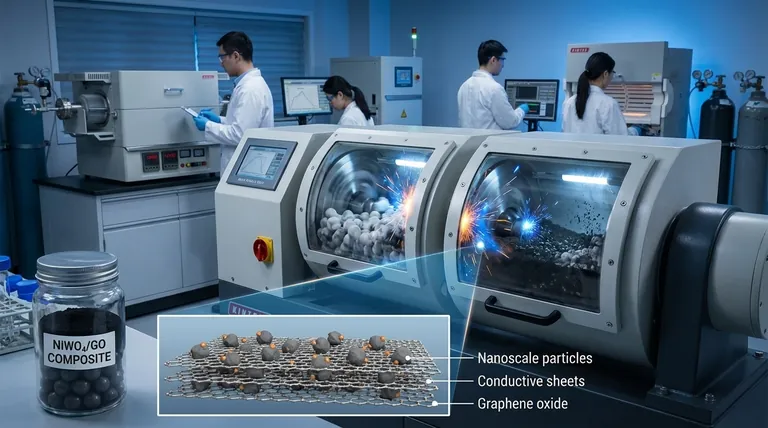

High-energy ball milling serves as the critical mechanical catalyst for synthesizing high-performance Nickel Tungstate (NiWO4) and Graphene Oxide (GO) composites. Through the generation of powerful impact and friction forces via grinding media, the device physically refines NiWO4 particles and drives their uniform adsorption onto the conductive GO network.

By replacing complex chemical synthesis with high-impact mechanical force, this process ensures that active particles are uniformly anchored to a conductive backbone, directly enhancing the material's electrochemical efficiency.

The Mechanics of Composite Formation

Generating Impact and Friction

The core function of the high-energy ball mill is the application of intense kinetic energy.

Grinding media within the mill collide with the raw materials, generating significant impact and friction. This mechanical stress is the driving force that facilitates the integration of the two distinct materials.

Particle Refinement

The high-energy environment does more than simply mix the powders; it actively alters their physical state.

The process achieves particle refinement, breaking down the NiWO4 into smaller, more manageable units. This reduction in size is essential for maximizing the surface area available for interaction with the graphene oxide.

Creating the Structural Architecture

Uniform Surface Anchoring

The primary structural goal of this process is the creation of a cohesive composite rather than a loose mixture.

The mechanical forces cause the refined NiWO4 particles to anchor uniformly onto the surface of the graphene oxide. This ensures that the active material (NiWO4) is in constant, direct contact with the conductive substrate.

Establishing the Conductive Network

Graphene oxide serves as a conductive framework or "skeleton" for the composite.

By physically embedding the NiWO4 onto the GO, the ball milling process leverages the conductive network of the graphene. This architecture allows the composite to utilize the inherent electrical properties of graphene effectively.

Enhancing Electrochemical Performance

Shortening Ion Migration Paths

The structural arrangement achieved by ball milling has direct functional benefits for electrode performance.

The intimate contact between the particles and the graphene sheets shortens the paths that ions must travel during electrochemical reactions. This efficiency leads to faster reaction kinetics.

Boosting Electronic Conductivity

The ultimate result of this mechanical integration is a significant upgrade in electrical capability.

The uniform distribution of particles on the conductive GO network enhances the overall electronic conductivity of the electrode. This makes high-energy ball milling a key method for constructing high-performance composite architectures.

Understanding the Trade-offs

Risk of Structural Damage

While high energy is necessary for integration, it presents a risk to the material's integrity.

Excessive impact or prolonged milling times can physically damage the graphene oxide sheets, breaking the conductive network you are trying to utilize. Balancing the energy input is critical to maintaining the structural stability of the GO.

Potential for Impurities

The friction that drives the process can also act as a source of contamination.

As grinding media impacts the materials, microscopic wear from the balls or jar can introduce impurities into the NiWO4/GO mixture. This requires careful selection of grinding media hardness relative to the composite materials.

Making the Right Choice for Your Goal

To maximize the effectiveness of high-energy ball milling for your specific application, consider the following priorities:

- If your primary focus is Ion Transport: Ensure the milling duration is sufficient to achieve maximum particle refinement, minimizing the distance ions must travel.

- If your primary focus is Electronic Conductivity: Prioritize the uniformity of the mixture to ensure the NiWO4 is evenly anchored across the entire graphene oxide network without agglomeration.

Mastering the mechanical intensity of the ball mill allows you to precisely engineer the interface between active particles and conductive supports, unlocking superior electrode performance.

Summary Table:

| Key Function | Mechanical Action | Direct Benefit |

|---|---|---|

| Particle Refinement | Intense impact and friction | Maximizes surface area for higher reactivity |

| Surface Anchoring | Uniform physical adsorption | Ensures NiWO4 is securely fixed to the GO network |

| Structural Architecture | Creation of a conductive skeleton | Shortens ion migration paths for faster kinetics |

| Electrochemical Boost | Integration of active/conductive phases | Enhances overall electronic conductivity and efficiency |

Elevate Your Composite Synthesis with KINTEK Precision

Ready to achieve superior material refinement and electrochemical performance? Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory solutions, including specialized High-Energy Ball Mills, Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable for your unique research needs.

Whether you are developing advanced NiWO4/GO composites or next-generation electrode materials, our team of experts is here to provide the high-performance tools your lab requires.

Contact us today to find the perfect solution for your research!

Visual Guide

References

- Likai Deng, Shifa Wang. Advanced Electrochemical Performance of NiWO4/Graphene Oxide as Cathode Material for Zinc Ion Battery. DOI: 10.3390/en18082023

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the effect of sintering BZCYYb electrolyte pellets at 1000°C? Boost Your PCFC Performance Today

- What are the energy-saving advantages of using a SHS system for tungsten carbide? Cut Energy Costs by up to 90%

- What are the typical functions performed by laboratory furnaces? Unlock Precise Thermal Processing for Your Materials

- Why is immediate water quenching required for CuAlMn alloys? Master Phase Retention in Shape Memory Alloys

- What is the primary function of an industrial-grade electric oven for concrete? Optimize High-Temp Material Testing

- What are the advantages of using a batch furnace? Achieve Unmatched Process Flexibility and Precision

- How is the graphitization degree quantified using Raman spectroscopy? Master the $I_D/I_G$ Ratio for Carbon Materials

- How does the pulling and rotation control system of a Czochralski growth furnace affect crystal quality?