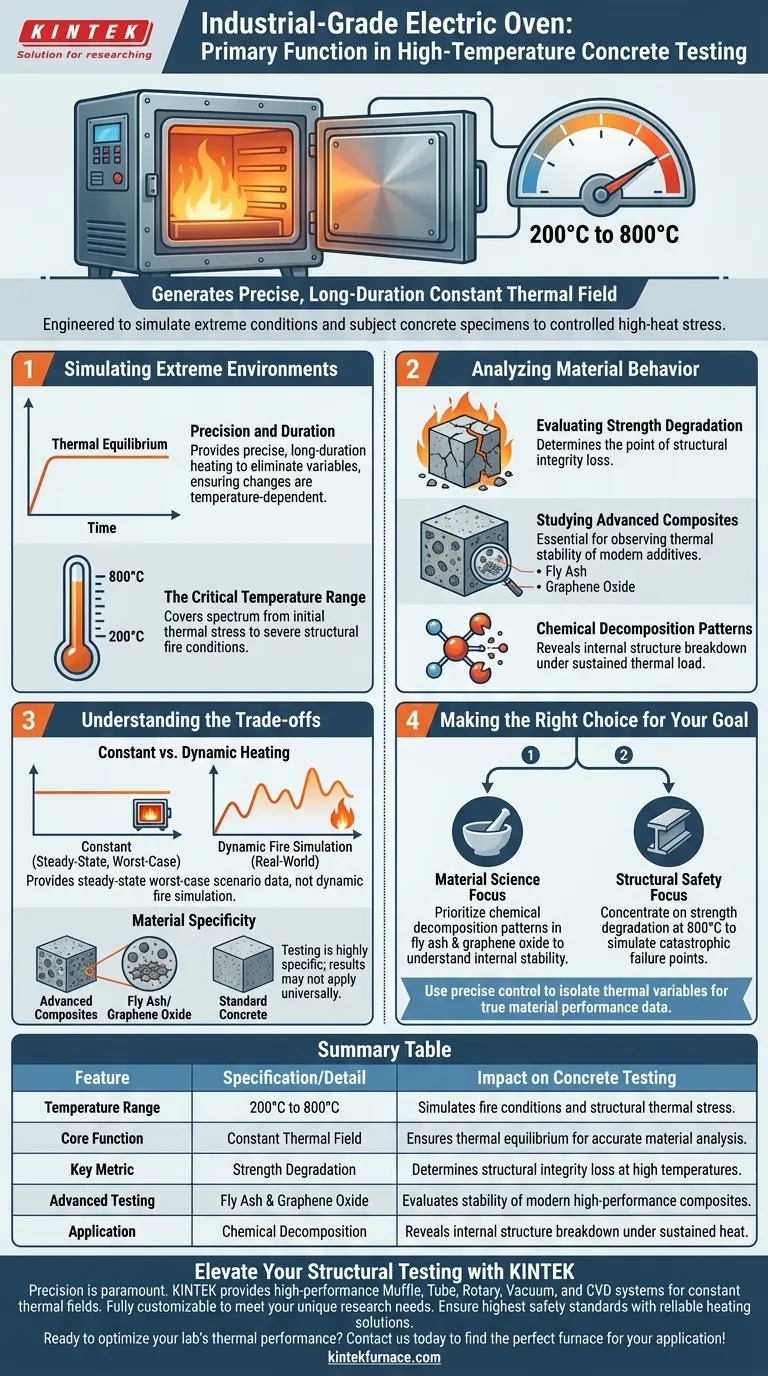

The primary function of an industrial-grade electric oven in concrete testing is to generate a precise, long-duration constant thermal field. These units are engineered to simulate extreme environmental conditions, typically ranging from 200°C to 800°C, allowing researchers to subject concrete specimens to controlled high-heat stress.

By maintaining a stable, high-temperature environment, these ovens allow for the critical evaluation of thermal stability and strength degradation in advanced concrete composites. This testing is essential for understanding how materials like fly ash and graphene oxide behave under fire-simulated conditions.

Simulating Extreme Environments

To accurately assess how concrete will perform during a fire or high-heat event, the testing environment must be rigorously controlled.

Precision and Duration

The oven's role goes beyond simply heating a specimen. It must provide precise, long-duration heating to ensure the material reaches thermal equilibrium.

This consistency eliminates variables, ensuring that any changes observed in the concrete are due to the temperature itself, not fluctuations in the heating source.

The Critical Temperature Range

Industrial-grade ovens for this purpose typically operate between 200°C and 800°C.

This specific range is crucial because it covers the spectrum from initial thermal stress to the temperatures found in severe structural fires.

Analyzing Material Behavior

The core purpose of this thermal application is to study the physical and chemical changes within the concrete matrix.

Evaluating Strength Degradation

One of the most critical metrics evaluated is strength degradation.

By subjecting specimens to fire-simulated conditions, engineers can determine at what point the concrete loses its structural integrity.

Studying Advanced Composites

Modern concrete often includes additives to improve performance. The oven is essential for studying fly ash and graphene oxide composites.

Researchers use the controlled heat to observe the specific thermal stability of these composite materials.

Chemical Decomposition Patterns

High heat causes chemical reactions within the concrete.

The oven facilitates the study of chemical decomposition patterns, revealing how the internal structure of the material breaks down under sustained thermal load.

Understanding the Trade-offs

While industrial electric ovens are vital for material characterization, understanding their operational context is key to interpreting results.

Constant vs. Dynamic Heating

The primary reference highlights the oven's ability to provide constant temperature heating.

However, real-world fires are rarely constant; they fluctuate dynamically. Therefore, data from these ovens represents a "steady-state" worst-case scenario rather than a dynamic fire simulation.

Material Specificity

The testing described is highly specific to materials like fly ash and graphene oxide composites.

Standard concrete mixes may behave differently, meaning the decomposition patterns observed in these advanced composites may not universally apply to all concrete types.

Making the Right Choice for Your Goal

When designing a testing protocol using an industrial-grade electric oven, align your parameters with your specific research objectives.

- If your primary focus is material science: Prioritize the analysis of chemical decomposition patterns in fly ash and graphene oxide to understand internal stability.

- If your primary focus is structural safety: Concentrate on evaluating strength degradation at the upper end of the 200°C to 800°C range to simulate catastrophic failure points.

Use the precise control of these ovens to isolate thermal variables, ensuring your data reflects true material performance under fire-simulated conditions.

Summary Table:

| Feature | Specification/Detail | Impact on Concrete Testing |

|---|---|---|

| Temperature Range | 200°C to 800°C | Simulates fire conditions and structural thermal stress. |

| Core Function | Constant Thermal Field | Ensures thermal equilibrium for accurate material analysis. |

| Key Metric | Strength Degradation | Determines structural integrity loss at high temperatures. |

| Advanced Testing | Fly Ash & Graphene Oxide | Evaluates stability of modern high-performance composites. |

| Application | Chemical Decomposition | Reveals internal structure breakdown under sustained heat. |

Elevate Your Structural Testing with KINTEK

Precision is paramount when simulating fire conditions or analyzing the thermal stability of advanced concrete composites. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to deliver the constant thermal fields required for rigorous high-temperature testing.

Whether you are evaluating strength degradation or chemical decomposition patterns, our industrial-grade furnaces are fully customizable to meet your unique research needs. Ensure your materials meet the highest safety standards with our reliable heating solutions.

Ready to optimize your lab's thermal performance? Contact us today to find the perfect furnace for your application!

Visual Guide

References

- I. Ramana, N. Parthasarathi. Synergistic effects of fly ash and graphene oxide composites at high temperatures and prediction using ANN and RSM approach. DOI: 10.1038/s41598-024-83778-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of high-precision furnaces in Inconel 718 heat treatment? Master Microstructural Engineering

- How does temperature control precision affect c-BAs crystal growth? Ensure Lattice Integrity in Two-Week Cycles

- Why is high-temperature hydrogen reduction used for HI decomposition catalysts? Boost Efficiency and Surface Purity

- What are the advantages of HTL reactors for algae? Optimize Biomass Conversion Without Pre-Drying

- What are the functions of hydrogen gas for graphene on silver? Enhance Crystallinity & Stability

- Why use liquid nitrogen freezing & vacuum freeze-drying for cement and biomass hydration? Preserve Microstructure Now

- How does a vacuum drying oven contribute to biodiesel moisture control? Ensure Fuel Quality & Stability

- What is the function of an industrial drying oven in PET waste pretreatment? Optimize Your Activated Carbon Production